Practical Methods of Providing Concrete Cover to Reinforcement

The concrete cover thickness is a major protection measure that prevents corrosion and deterioration of reinforcement steel bars. There are number of approaches that have been used to make sure that the exact required cover thickness is obtained during construction.

This article will shed light on the different practical techniques used to execute and maintain concrete cover during building construction process so as to match the cover thickness specified in the design.

Fig.1: Plastic spacer for maintaining concrete cover during concrete pouring

Fig.2: Concrete spacer used to maintain accurate concrete cover during construction

Methods of Providing Concrete Cover During Construction

Application of Concrete Cuboids (Biscuits)

This technique is one of the most well known practical methods used to execute concrete cover. Commonly, the dimension of biscuit is 50x100mm and its thickness varies based on the concrete cover thickness requirement.

Figure 3 shows the application of pieces of concrete cuboids in the construction of reinforced concrete slab.

Fig.3: Utilization of concrete cuboids to make sure that designed cover thickness is maintained during construction

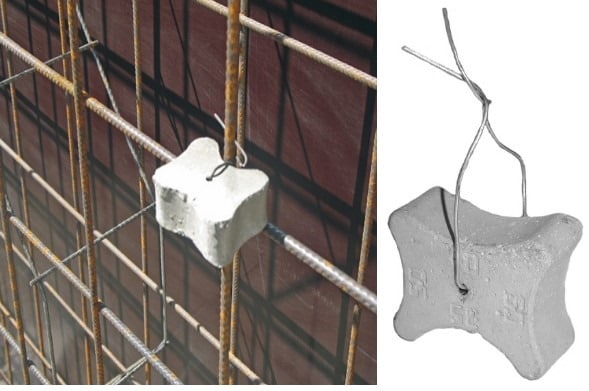

Steel wires are inserted into biscuits to tie steel bars to cuboids and keep the required spacing between bars as shown in Figure 4.

Fig.4: Steel wire used to tie concrete cuboids with steel bras

The most outstanding advantage of biscuit is that they are cost effective. With regard to concrete cuboids disadvantage, cuboids might be cracked and damaged due to concentrated loads that imposed by workers when they are move along bars to pour concrete or to inspect and supervise the construction process.

So, if biscuits are cracked and damaged, then they would not serve their purpose which is to maintain the designed concrete cover thickness during construction process.

Utilization of Plastic Pieces for Concrete Cover

This technique is assumed to the most practical one compare with other methods. Not only does the cost of plastic pieces is low but also it executes the cover thickness accurately since it can bear great loads due to its high strength. That is why the application of these plastics has recently been increased significantly.

Various types of plastics are produced based on the diameter and forms of the bar, thickness of concrete cover, and the location of steel bars.

Different forms of plastic pieces are shown from Figure 5 to Figure 7.

Fig.5: Round plastic spacer used to maintain concrete cover during construction

Fig.6: Plastic A clip spacer

Fig.7: Plastic pieces used to keep accurate concrete cover during construction

Plastic pieces would stabilize reinforcement bars and maintain cover thickness of different reinforced concrete elements such as beams, columns, slabs, and foundations.

When a customer makes an order, the supplier should receive certain information from the customer. This information includes quantity and thickness of concrete cover, diameter of steel bars which will be utilized, and type of reinforced concrete element that will be constructed since type of plastic would vary according to the type of members like columns, beams, and slabs.

Moreover, there are certain types of plastics which are specifically manufactured for intersection of steels as shown in Figure 8.

Fig.8: Plastic pieces at steel intersection

Not only does this type of cuboids maintain the cover thickness but also prevent the movement of steel bars and consequently keep the required spacing reinforcements.

Finally, biscuits can also be employed to support chairs which are beneficial to protect steel bars that are exposed to concrete’s outer surface.

Use of Aggregate Beneath Steel Bars for Concrete Cover

The application of suitable size of aggregate beneath steel bars is another method to maintain concrete cover thickness that has been employed prior to the previous techniques.

But this method is not acceptable nowadays since it does not guarantee proper execution of designed cover thickness.

However, the application of using proper aggregate size underneath steel bars has not stopped totally and it is still employed in low cost buildings in certain developed countries.

Nonetheless, it is shown that, this method lead to improper execution of concrete cover thickness and consequently steel bars would suffer corrosion.

The repair cost of deteriorated concrete element is higher than cost of the use of plastic pieces and concrete cuboids. That is why, certain specification requires the measurement of concrete cover thickness in structures exposed to sever condition.

For example, British Standard states that, concrete cover thickness should be measured according to BS 1881 part 204 employing electromagnetic devices. Such device measures the cover thickness and size of embedded bars.

According to the British standard, the measured cover thickness should not be smaller than needed nominal cover minus 5mm.

Finally, it is necessary to check reinforcements and nominal concrete cover both before and during placement in order to decrease or eliminate errors.

No comments:

Post a Comment