Initial Setting Time and Final Setting Time of Concrete

Initial setting time of concrete is the time when cement paste starts hardening while final setting time is the time when cement paste has hardened sufficiently in such a way that 1 mm needle makes an impression on the paste in the mould but 5 mm needle does not make any impression.

Theoretically, Initial setting time of concrete is the time period between addition of water to cement till the time at 1 mm square section needle fails to penetrate the cement paste, placed in the Vicat’s mould 5mm to 7mm from the bottom of the mould. Final setting time is that time period between the time water is added to cement and the time at which 1 mm needle makes an impression on the paste in the mould but 5 mm attachment does not make any impression.

Table of Contents

Technical Aspects of Concrete Setting Times

- It is essential that cement set neither too rapidly nor too slowly. In the first case there might be insufficient time to transport and place the concrete before it becomes too rigid. In the second case too long a setting period tends to slow up the work unduly, also it might postpone the actual use of the structure because of inadequate strength at the desired age.

- Setting should not be confused with hardening, which refers to the gain in mechanical strength after the certain degree of resistance to the penetration of a special attachment pressed into it.

- Setting time is the time required for stiffening of cement paste to a defined consistency.

- Indirectly related to the initial chemical reaction of cement with water to form aluminum-silicate compound.

- Initial setting time is the time when the paste starts losing its plasticity.

- Initial setting time test is important for transportation, placing and compaction of cement concrete.

- Initial setting time duration is required to delay the process of hydration or hardening.

- Final setting time is the time when the paste completely loses its plasticity.

- It is the time taken for the cement paste or cement concrete to harden sufficiently and attain the shape of the mould in which it is cast.

- Determination of final setting time period facilitates safe removal of scaffolding or form.

- During this period of time primary chemical reaction of cement with water is almost completed.

Procedure to Find Setting Time of Cement

Apparatus Required

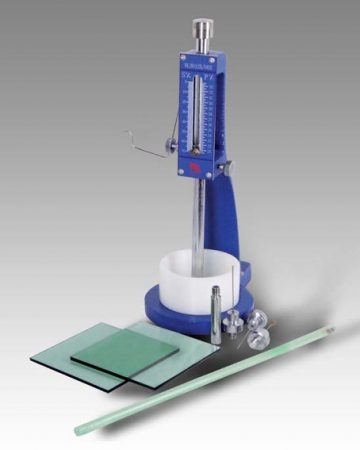

- Vicat’s apparatus

- Balance

- Measuring cylinder

- Stop watch

- Glass plate

- Enamel tray

- Trowel

Test Procedure

Initial Preparation

- Consistency test to be done before starting the test procedure to find out the water required to give the paste normal consistency (P).

- Take 400 g of cement and prepare a neat cement paste with 0.85P of water by weight of cement.

- Gauge time is kept between 3 to 5 minutes. Start the stop watch at the instant when the water is added to the cement. Record this time (T1).

- Fill the Vicat mould, resting on a glass plate, with the cement paste gauged as above. Fill the mould completely and smooth off the surface of the paste making it level with the top of the mould. The cement block thus prepared is called test block.

Fig 1: Vicat’s Apparatus used for determination of setting time of cement

Test for Initial Setting Time

- Place the test block confined in the mould and resting on the non-porous plate, under the rod bearing the needle.

- Lower the needle gently until it comes in contact with the surface of test block and quick release, allowing it to penetrate into the test block.

- In the beginning the needle completely pierces the test block. Repeat this procedure i.e. quickly releasing the needle after every 2 minutes till the needle fails to pierce the block for about 5 mm measured from the bottom of the mould. Note this time (T2).

Test for Final Setting Time

- For determining the final setting time, replace the needle of the Vicat’s apparatus by the needle with an annular attachment.

- The cement is considered finally set when upon applying the final setting needle gently to the surface of the test block; the needle makes an impression thereon, while the attachment fails to do so. Record this time (T3).

Calculations

Initial setting time=T2-T1

Final setting time=T3-T1

Where,

T1 =Time at which water is first added to cement

T2 =Time when needle fails to penetrate 5 mm to 7 mm from bottom of the mould

T3 =Time when the needle makes an impression but the attachment fails to do so.

Standard Specification of Setting Time for Different Type of Cement

Depending upon the admixtures added into the cement in the process of manufacture of cement, the setting time differs for different cement. Standard setting times are listed in the below table as per IS Codes.

Table-1: Setting Time for Different Type of Cement

| Cement Type | Initial Setting Time, min (min.) | Final Setting Time, min (max.) |

| OPC(33) | 30 | 600 |

| OPC(43) | 30 | 600 |

| OPC(53) | 30 | 600 |

| SRC | 30 | 600 |

| PPC | 30 | 600 |

| RHPC | 30 | 600 |

| PSC | 30 | 600 |

| High alumina | 30 | 600 |

| Super sulphated | 30 | 600 |

| Low heat | 60 | 600 |

| Masonry cement | 90 | 1440 |

| IRS-T-40 | 60 | 600 |

No comments:

Post a Comment