Difference between Control Joint and Expansion Joint?

Control Joint in Concrete

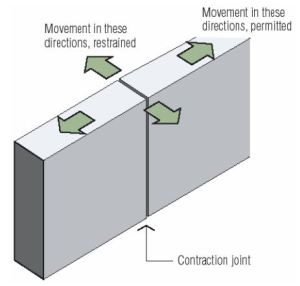

Control joints in concrete are provided at regular interval to from a weak plane, so that cracks are formed at the joints but not in undesired places. Control joints are provided in concrete pavements, slabs, walls, floors, dams, canal linings, bridge, retaining walls etc.

When concrete is placed, due to shrinkage, creep and thermal movement concrete tends to reduce in size due to which small cracks are formed in the concrete at weak zone.

Need of Control joint in Concrete

Concrete tends to shrink or reduce in size when it starts hardening. This shrinkage of concrete creates tensile stresses in the concrete which develops the minute cracks at the weak plane.

These cracks are restricted and prevent the formation of large cracks due to the presence of reinforcement in the concrete. But if its unreinforced concrete, the small cracks tends to develop into a large cracks at irregular interval. To prevent such cracks, control joints must be installed at appropriate intervals. It is also recommended to install these joints in reinforced concrete too.

Location of Contraction Joint

Generally these joints are pre-defined in the drawings given by designer or architect. If not defined, they will be in a regular pattern or be an integral part of the architectural features. Control joints form a convenient point at which to stop concrete work at the end of the day. Control joints should never be formed in the middle of a bay.

Control joint is placed at the location of highest concentration of tensile stresses resulting from shrinkage are expected:

- At abrupt changes of cross-section; and

- In long walls, slabs.

Expansion Joint in Concrete

Expansion joints are placed in concrete to prevent expansive cracks formed due to temperature change. Concrete undergoes expansion due to high temperature when in a confined boundary which leads to cracks. Expansion joints are provided in slabs, pavements, buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Need of Expansion Joint in Concrete

Concrete is not an elastic substance, and therefore it does not bend or stretch without failure. However, concrete moves during expansion and shrinkage, due to which the structural elements shift slightly.

To prevent harmful effects due to concrete movement, several expansion joints are incorporated in concrete construction, including foundations, walls, roof expansion joints, and paving slabs.

These joints need to be carefully designed, located, and installed. If a slab is positioned continuously on surfaces exceeding one face, an expansion joint will be necessary to reduce stresses. Concrete sealer may be used for the filling of gaps produced by cracks.

Characteristics of Expansion Joints

- Expansion joints permits thermal contraction and expansion without inducing stresses into the elements.

- An expansion joint is designed to absorb safely the expansion and contraction of several construction materials, absorb vibrations, and permit soil movements due to earthquakes or ground settlement.

- The expansion joints are normally located between sections of bridges, paving slabs, railway tracks, and piping systems.

- The expansion joints are incorporated to endure the stresses.

- An expansion joint is simply a disconnection between segments of the same materials.

- In the concrete block construction, the expansion joints are expressed as control joints.

Types of Expansion Joint

Based on the location of joint, expansion joints are divided into following types,

- Bridge expansion joints

- Masonry Expansion Joint

- Railway Expansion Joints

- Pipe Expansion Joints

Based on the type of material used in making of joint, expansion joints are further classified into following types,

- Rubber expansion joint

- Fabric expansion joint

- Metal expansion joint

- Toroidal expansion joint

- Gimbal expansion joint

- Universal expansion joint

- In-line expansion joint

- Refractory lined expansion joint

No comments:

Post a Comment