Construction of Concrete Block Retaining Walls with Steps

How to Build Concrete Block Retaining Walls?

Construction of concrete block retaining walls, with step by step process, materials, advantages, applications and its construction inspection are discussed.

Retaining wall structure is commonly constructed to retain earth mass or back fill materials. It is constructed in various engineering projects to serve different purposes.

There are different types of retaining wall such as reinforced concrete retaining wall, segmental retaining wall, gabion wall and concrete block retaining wall.

The focus of this article will be on the construction of concrete block retaining wall.

Fig.1: Concrete Block Retaining Wall (SEXTON, 2017)

Fig.2: Concrete Block Retaining Wall (GADANG, 2017)

Following topics regarding construction of concrete block retaining walls are discussed:

- Advantages and application of concrete block masonry wall

- Concrete block retaining wall construction steps

- Construction inspection

Advantages of Applications of Concrete Block Retaining Wall

- It retains backfill materials.

- It eliminates slopes of earth or earth fill materials.

- It helps in control of erosion.

- Concrete block retaining wall is simple and easy to construct.

- It is cost effective.

- It is durable compared to other types of retaining walls.

Construction of Concrete Block Retaining Wall with Steps

Concrete block retaining wall construction consists of number of phases including excavation, foundation soil preparation, retaining wall base construction, concrete block unit placement, grouting and drainage system installation. These phases are explained briefly:

Excavation Work for Concrete Block Retaining walls

Proper machines or tools should be selected and used for this purpose and undisturbed and satisfactory strong soil can be reached after the removal of the soil.

The work should be carried out based on the lines and grades provided by the retaining wall design drawings. Considerable care should be practiced to prevent excessive excavation.

It should be remembered that the position of structures and utilities at the vicinity of the project site should be specified and necessary measures should be taken to prevent damages because of excavation work.

Fig.3: Site Excavation and Grading for Retaining Wall Construction

Foundation Soil Preparation for Concrete Block Retaining walls

Foundation soil under the basement should be excavated in accordance with drawings of the concrete block retaining wall design. It should be compacted to at least 95% standard proctor compaction test.

Site engineer should explore and examine foundation soil to ensure that it meets the requirements of the design. If the soil foundation does not meet the design requirements, it should be replaced with acceptable material.

Fig.4: Compaction of foundation Soil (Ref. Properly Compacting Soil When Building a Retaining Wall, Part 2, 2011)

Construction of Concrete Block Retaining Wall Base

Similar to other part of the retaining wall, the placement of base material should be carried out as per drawings provided. It is recommended to consider low permeable granular material as a base material and this soil layer is placed on foundation soil.

When base materials are placed, adequate depth should be lifted according to recommendations of applicable codes or design documents to install and bury the bottom of the wall.

The base material need to be compacted at 95% standard proctor and the top surface is advised to be leveled using 13mm thickness of well graded sand.

Fig.5: Retaining Wall Base Material Leveling (KOWALSKI, 2008)

The thickness of the base material is based on the height of retaining wall. For example, 100mm can be adopted for heights less than 1.2m and 150mm for heights greater than 1.2m.

Fig.6: Retaining Wall Base Material Compaction (KOWALSKI, 2008)

Concrete Block Unit Placement in Retaining Wall

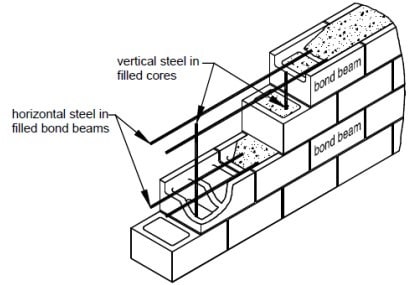

Concrete block units should be installed properly in accordance with design documents and need to be plumbed. They should be placed cells vertical and mortar need to be applied for all sides of the block both in horizontal and vertical directions. It should be guaranteed that first course of the wall should adequately be in contact with base material.

The horizontal and vertical mortar joint thickness should not be smaller than 10mm. If joints are visible, then concave joint section should be created otherwise the finishing work will be struck with trowel.

It is recommended to use a mortar of 1 cement or 1 lime: 6 sand or 1 cement: 5 sand plus water thickener. If the retaining wall is reinforced with steel bars, then cell should be cleaned from the first course using proper means and techniques.

The cleaning is considerably advantageous since the position of the steel bars would be influenced by debris in the spaces.

Additionally, mortars that stick into the spaces should be removed either along construction progression or after completion of block placement. Weep holes are required to be placed at a recommended spacing of 1200mm.

The reinforcement bars are embedded into the space of the wall and fastened sufficiently to prevent their disposition.

Fig.7: Reinforcement Placement in Concrete Block Retaining Wall

Fig.8: Typical Placement of Horizontal and Vertical Reinforcement in Concrete Block Masonry Wall

Fig.9: Detailing of Reinforced Concrete Block Retaining Wall

Grouting of Concrete Block Retaining Wall

Grouting process carried out as follow:

- Seal clean out holes.

- Pour the grout and ensure that all spaces are filled adequately with grout to produce the best possible bond in the wall.

- Voids in the grout should be eliminated by applying compaction.

- Building code requirement for masonry structures and commentary provides minimum space requirements for grouting which can be seen in Table 1.

Table-1: Grout Space Requirements (MSJC, 2011)

| Grout type | Maximum grout pour height, m | Minimum clear width of grout space, mm | Minimum clear grout space dimensions for grouting cells of hollow units, mm x mm |

| Fine | 0.3 | 19.1 | 38.1 x 50.8 |

| Fine | 1.63 | 50.8 | 50.8 x 76.2 |

| Fine | 3.86 | 63.5 | 63.5 x 76.2 |

| Fine | 7.32 | 76.2 | 76.2 x 76.2) |

| Coarse | 0.30 | 38.1 | 38.1 x 76.2 |

| Coarse | 1.63 | 50.8 | 63.5 x 76.2 |

| Coarse | 3.86 | 63.5 | 76.2 x 76.2 |

| Coarse | 7.32 | 76.2 | 76.2 x 102 |

Construction Inspection of Concrete Block Retaining Wall

It is necessary to conduct inspection at various construction phases which are explained below:

- Inspection would be necessary after the completion of foundation excavation work and reinforcement placement, and it should be conducted prior to concrete pouring.

- Before the placement of grouts, after concrete blocks are placed and steel bars are inserted.

- Prior to the placement of backfill material.

- Finally, after the entire construction work is ended.

No comments:

Post a Comment