Types of Joints in Concrete Water Tank Structures and their Spacings

There are different types of joints which are provided in the reinforced concrete water tank structures for different purposes such as to contain different movements and during construction process. This article presents various types of joints provided in water tanks structures.

Movement joints

Movement joints are introduced to contain relative movements between different types of the structure. This type of joints may not be needed in elevated water tanks since restraints are small. There are three types of movement joints which are discussed below:

1. Contraction Joint

- Contraction joint purpose is to contain contraction of concrete.

- It is a movement joint with deliberate discontinuity without initial gap between the concrete on either side of the joint.

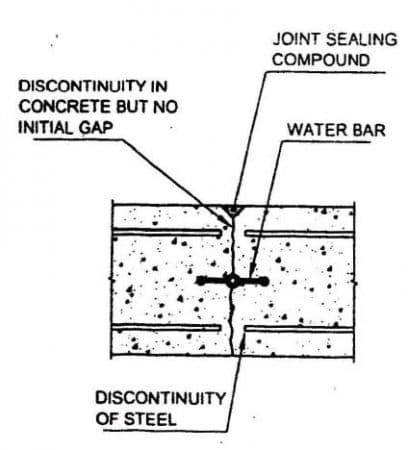

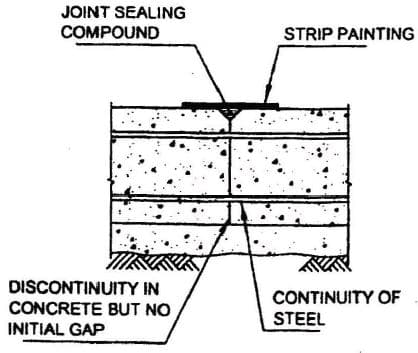

- A contraction joint may be either complete contraction joint (Fig.1) or partial contraction joint (Fig.3).

- complete contraction joint is one in which both steel and concrete are interrupted.

- In complete contraction joint, the mouth of the joint is filled with joint sealing compound and then strip painted.

- partial contraction joint is one in which only the concrete is interrupted, the reinforcing steel running through.

2. Expansion Joint

- expansion joint provided to contain either expansion or contraction of concrete.

- It is a joint with complete discontinuity in both reinforcing steel and concrete.

- This type of joint requires the provision of an initial gap between the adjoining parts of a structure which by closing or opening accommodates the expansion or contraction of the structure.

- The initial gap is filled with joint filler.

- Joint fillers are usually compressible sheet or strip materials used as spacers.

- With an initial gap of 30 mm, the maximum expansion or contraction that the filler materials may allow may be of the order of 10 mm.

- An expansion type water bar shall be provided either centrally in a wall or on the soffit of a floor.

3. Sliding Joint

- It is a joint with complete discontinuity in both reinforcement and concrete and with special provision to facilitate movement in plane of the joint.

- This type of joint is provided between wall and floor in some cylindrical tank designs.

- It allows two structural members to slide relative to one another with minimal restraint.

Construction joints

- This type of joint is provided for convenience in construction.

- Arrangement is made to achieve subsequent continuity without relative movement.

- One application of these joints is between successive lifts in a reservoir wall.

- The number of joints should be as small as possible and these joints should be kept from possibility of percolation of water.

- The position and arrangement of all construction joints should be predetermined by the engineer.

Temporary joint

- A temporary open joint is a gap temporarily left parts of a structure, which after a suitable interval and before the structure is put into use, is filled with mortar or concrete completely as shown in fig, or with the inclusion of suitable jointing material as illustrated in.

- when the gap is filled with concrete, width of gap should be sufficient to allow the sides to be prepared before filling.

Spacing between joints of water tank structures

Unless alternative effective means are taken to avoid cracks by al lowing for the additional stresses that may be induced by temperature or shrinkage changes or by unequal settlement, movement joints should be provided at the following spacing:

- In reinforced concrete floors, movement joints should be spaced at not more than 7.5m apart in two direct ions at right angles.

- For floors with only nominal percentage of reinforcement (smaller than the minimum specified) the concrete floor should be cast in panels with sides not more than 4.5m.

- In concrete walls, the movement joints should normally be placed at a maximum spacing of 7.5m. In reinforced walls and 6m in unreinforced walls.

- expansion joints should normally be provided at a spacing of not more than 30m between successive expansion joints or between the end of the structure and the next expansion joint.

- When, however, the temperature changes to be accommodated are abnormal or occur more frequently than usual as in the case of storage of warm liquids or in uninsulated roof slabs, a smaller spacing than 30m should be adopted that is greater proportion of movement joints should be of the expansion type).

- When the range of temperature is small, for example, in certain covered structures, or where restraint is small, for example, in certain elevated structures none of the movement joints provided in small structures up to 45m length need be of the expansion type.

No comments:

Post a Comment