Contraction Joint in Concrete – Their Location and Construction

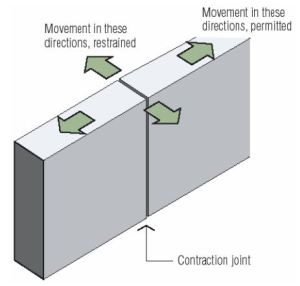

Contraction joints in concrete are provided at regular interval to from a weak plane, so that cracks are formed at the joints but not in undesired places. Contraction joints are provided in concrete pavements, slabs, walls, floors, dams, canal linings, bridge, retaining walls etc.

When concrete is placed, due to shrinkage, creep and thermal movement concrete tends to reduce in size due to which small cracks are formed in the concrete at weak zone.

In this article we discuss about the need of contraction joints, how to make a contraction joint and locating a contraction joint.

Need of Contraction joint in Concrete

Concrete tends to shrink or reduce in size when it starts hardening. This shrinkage of concrete creates tensile stresses in the concrete which develops the minute cracks at the weak plane.

These cracks are restricted and prevent the formation of large cracks due to the presence of reinforcement in the concrete. But if its unreinforced concrete, the small cracks tends to develop into a large cracks at irregular interval

To prevent such cracks, contraction joints must be installed at appropriate intervals. It is also recommended to install these joints in reinforced concrete too.

Construction of Contraction Joint in Concrete

The main aim of providing a weak joint is to create a weak plane in the concrete at regular intervals where the possibility of cracking is more. These joints are placed to produce panels that are as square as possible and never exceed a length to width ratio of 1 ½ to 1. Joints are commonly spaced at distances equal to 24 to 30 times the slab thickness. The contraction joint is known as control joint.

The process of forming contraction joint can be done in any of 3 stages:

- While placing concrete, a premoulded strip may be inserted into the concrete to create a plane of weakness. Metal strips inserted into terrazzo or preformed plastic strips can be inserted into concrete pavements to avoid cracks.

- Saw cut joints or dry cut joints can be made after the placing of concrete. Saw-cut joints should be done within 4 to 12 hours after the concrete has been finished. Dry-cut joints should be made between 1 to 4 hours after completion of finishing. In this method, joints are made using hand grover or concrete saw and the concrete is cut at regular intervals and a permeable material is placed that bonds with concrete well.

- Once the concrete has hardened sufficiently, a sawn joint may be formed. The joint should be made as early as possible and prior to drying shrinkage starting to occur. Delay can result in unplanned cracking of the pavement. The sawn joint is then filled with a joint sealant to prevent dirt and other debris entering it, as unsealed joints tend to fill with dirt and become ineffective.

Materials used on concrete joints must be flexible enough to absorb or deform as needed and then being able to restore back to their original state.

Location of Contraction Joint

Generally these joints are pre-defined in the drawings given by designer or architect. If not defined, they will be in a regular pattern or be an integral part of the architectural features.

Contraction joints form a convenient point at which to stop concrete work at the end of the day. Construction joints should never be formed in the middle of a bay.

Contraction joint is placed at the location of highest concentration of tensile stresses resulting from shrinkage are expected:

- At abrupt changes of cross-section; and

- In long walls, slabs.

No comments:

Post a Comment