Types of High-Rise Buildings Structural Systems

A multistory building higher than 21m or 21 to 29 floor buildings with unknown height described as high-rise structure. Various structural systems are available to be used in the construction of high rise building.

In this article, different types of high rise structural systems are presented.

Types of High-Rise Buildings Structural Systems

1. Braced frame structural system

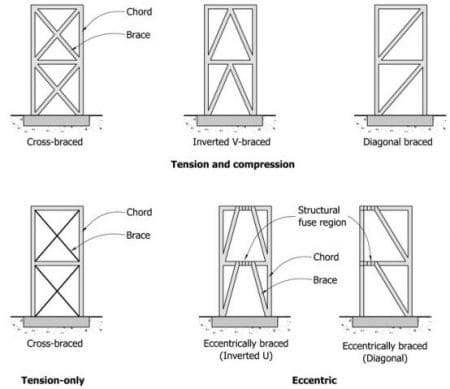

- Braced frames are cantilevered vertical trusses resisting laterals loads primarily diagonal members that together with the girders, form the “web” of the vertical truss, with the columns acting as the “chords’’.

- Bracing members eliminate bending in beams and columns.

Fig.1:Different bracing types

- It is used in steel construction

- This system is suitable for multistory building in the low to mid height range.

- efficient and economical for enhancing the lateral stiffness and resistance of rigid frame system.

- This system permits the use of slender members in a building.

- An outstanding advantage of braced frame is that, it can be repetitive up the height of the building with obvious economy in design and fabrication.

- However, it might obstruct internal planning and the location of doors and windows. That is why it shall be incorporated internally along with lines of walls and partitions.

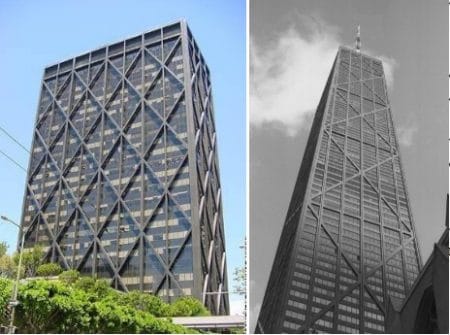

Fig.2:Braced frame structure

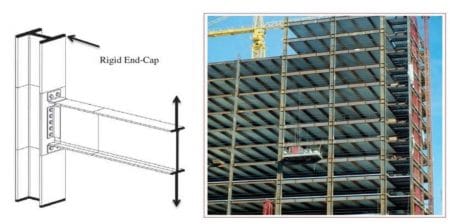

2. Rigid frame structural system

- In rigid frame structure, beams and columns are constructed monolithically to withstand moments imposed due to loads.

- The lateral stiffness of a rigid frame depends on the bending stiffness of the columns, girders and connections in-plane

- It is suitable for reinforced concrete buildings.

- It may be used in steel construction as well, but the connections will be costly.

- One of the advantages of rigid frames is the likelihood of planning and fitting of windows due to open rectangular arrangement.

- Members of rigid frame system withstand bending moment, shear force, and axial loads.

- 20 to 25 storey buildings can be constructed using rigid frame system.

- Advantages of rigid frame include ease of construction, labors can learn construction skills easily, construct rapidly, and can be designed economically.

- Maximum beam span is 12.2m and larger span beams would suffer lateral deflection.

- A disadvantage is that the self-weight is resisted by the action from rigid frames.

- Finally, Burj Al Khalifa which is the tallest structure in the world is constructed using rigid frame system.

Fig.3:Rigid frame structural system

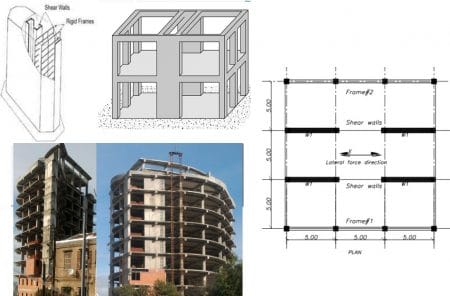

3. Wall-frame system (dual system)

- It consists of wall and frame that interact horizontally to provide stronger and stiffer system.

- The walls are usually solid (not perforated by openings) and they can be found around the stairwells, elevator shafts, and/or at the perimeter of the building.

- The walls may have a positive effect on the performance of the frames such as by preventing a soft storey collapse.

- Wall-frame system suitable for buildings with storey number ranges from 40-60 storey which is greater than that of shear or rigid frame separately.

- braced frames and steel rigid frames provide similar advantages of horizontal interaction.

Fig.4:wall frame system

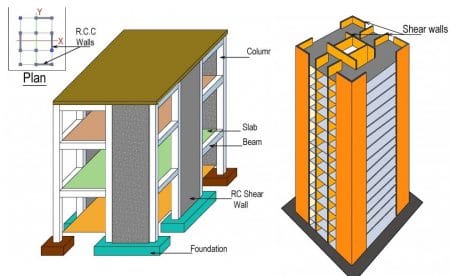

4. Shear wall system

- It is a continuous vertical wall constructed from reinforced concrete or masonry wall.

- Shear walls withstand both gravity and lateral loads, and it acts as narrow deep cantilever beam.

- Commonly, constructed as a core of buildings

- It is highly suitable for bracing tall buildings either reinforced concrete or steel structure. This because shear walls have substantial in plane stiffness and strength.

- Shear wall system is appropriate for hotel and residential buildings where the floor-by floor repetitive planning allows the walls to be vertically continuous.

- It may serve as excellent acoustic and fire insulators between rooms and apartments.

- shear wall structural system can be economical up to 35 stories building structure.

- Shear walls need not to be symmetrical in plan, but symmetry is preferred in order to avoid torsional effects.

Fig.5:shear walls system

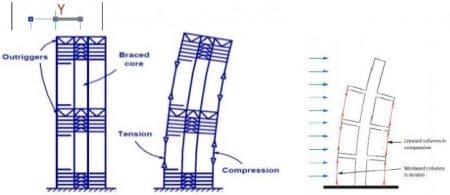

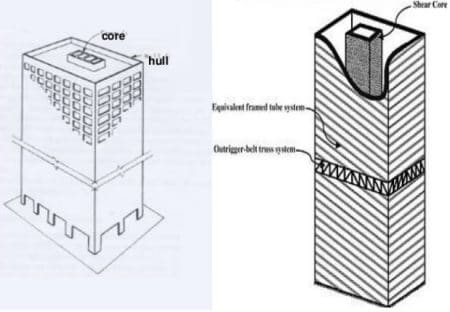

5. Core and outrigger structural system

- Outrigger are rigid horizontal structures designed to improve building overturning stiffness and strength by connecting the core or spine to closely spaced outer columns

- The central core contains shear walls or braced frames.

- Outrigger systems functions by tying together two structural systems (core system and a perimeter system), and render the building to behave nearly as composite cantilever.

- The outriggers are in form of walls in reinforced concrete building and trusses in steel structures.

- Multilevel outrigger systems can provide up to five times the moment resistance of a single outrigger system.

- Practically, Outrigger systems used for buildings up to 70 stories. Nonetheless, it can be used for higher buildings.

- Not only does the outrigger system decline building deformations resulting from the overturning moments but also greater efficiency is achieved in resisting forces.

Fig.6:Outtrigger structure system

6. Infilled frame structural system

- Infilled frame structure system consists of beam and column framework that some of the bays infilled with masonry, reinforced concrete, or block walls.

- Infill walls can be part-height or completely fill the frame.

- The walls may or may not be connected to the formwork.

- Great in plan stiffness and strength of the walls prevent bending of beams and columns under horizontal loads. As a result, frame structural performance will be improved.

- During an earthquake, diagonal compression struts form in the infills so the structure behaves more like a Braced Frame rather than a Moment Frame.

- It can build up to 30 storey buildings.

Fig.7:Infilled frame structure system

7. Flat plate and flat slab structural system

- This system consists of slabs (flat or plate) connected to columns (without the use of beams).

- flat plate is a two-way reinforced concrete framing system utilizing a slab of uniform thickness, the simplest of structural shapes.

- The flat slab is a two-way reinforced structural system that includes either drop panels or column capitals at columns to resist heavier loads and thus permit longer spans.

- Lateral resistance depends on the flexural stiffness of the components and their connections, with the slab corresponding to the girder of the rigid frame.

- Suitable for building up to 25 stories.

Fig.8:Flat slab and flat plate structure system

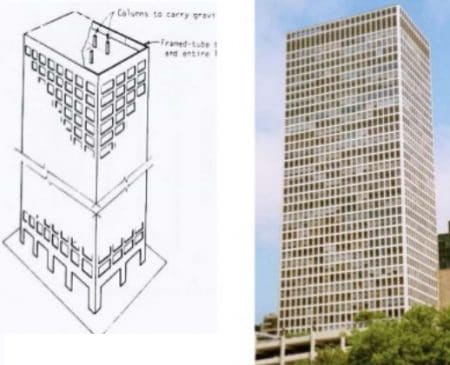

8. Tube structural system

- This system consists of exterior columns and beams that create rigid frame, and interior part of the system which is simple frame designed to support gravity loads.

- The building behaves like equivalent hollow tube.

- It is substantially economic and need half of material required for the construction of ordinary framed buildings.

- Lateral loads are resisted by various connections, rigid or semi-rigid, supplemented where necessary by bracing and truss elements.

- It is used for the construction of buildings up to 60 storeys.

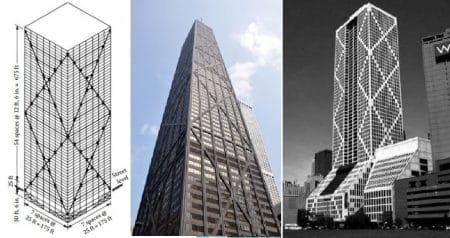

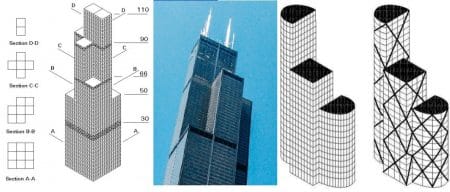

- Types of tube structure system include framed tube system (fig.9), trussed tube system (fig.10), bundled tube system (fig.11), and tube in tube system (fig.12).

- Trussed tube system is formed when external bracing added to make a structure stiffer. This structure type suitable for building up to 100 storeys.

- Bundled tube system consists of connected tubes and it withstand massive loads.

- A tube-in-tube system (hull core) is obtained, if the core is placed inside the tube frame structure.

Fig.9:Framed tube structure system

Fig.10:Trussed tube system

Fig.11:Bundled tube structure system

Fig.12:Tube in a tube system

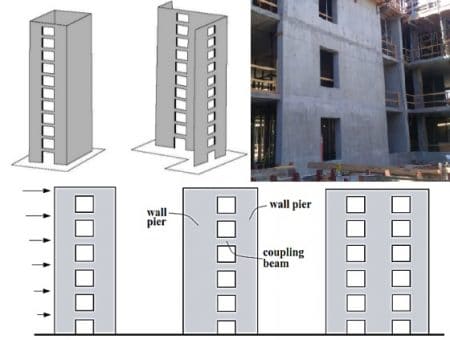

9. Coupled wall system

- This system composed of two or more interconnected shear walls

- Shear walls connected at the floor levels by beam or stiff slabs.

- Stiffness of the whole system is far greater than that of its components.

- The effect of the shear-resistant connecting members is to cause the sets of walls to behave in their partly as a composite cantilever, bending about the common centroidal axis of the walls.

- The system is suitable for buildings up to 40 storey height.

- Since planer shear walls support loads in their plane only, walls in two orthogonal directions need to withstand lateral loads in two directions.

Fig.13:Coupled wall system

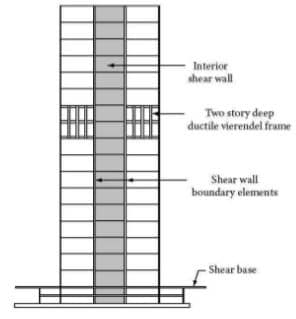

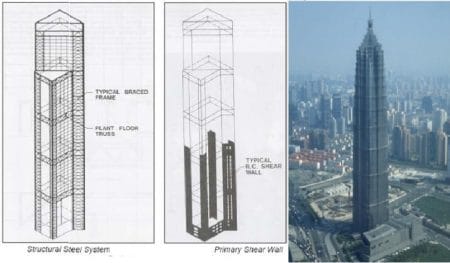

10. Hybrid structural system

- It is the combination of two or more of basic structural forms either by direct combination or by adopting different forms in different parts of the structure.

- Its lack of torsional stiffness requires that additional measures be taken, which resulted in one bay vertical exterior bracing and a number of levels of perimeter vierendeel “bandages”

Fig.14:Vierendeel frame

- It can be used for the buildings of as high as 300m.

- According to chines code (JGJ3-2002), hybrid system can be used for the construction of buildings with maximum 150m height in seismic regions.

Fig.15:Hybrid structure system

No comments:

Post a Comment