PRECAST METHOD OF BRIDGE CONSTRUCTION

Precast Method of Bridge Construction:

(i) Precast Beams:

Precast beam decks are generally used for short span bridges ranging between 5m to 50m – these may be railway or motorway bridges. Standard inverted tee beams or M-beams are chosen and positioned by crane.

Where precast beams are considered for a motorway bridge construction, the bridge cross-section for a typical carriageway will generally consist of four beams. Erection time of such bridge should have a rate of construction of four beams per day. A cast-in-situ slab top deck is normally used with an expected rate of construction of one span a week.

(ii) Precast Decks:

Precast deck construction is often used for the construction of long viaducts. It is a time saving method which is beneficial for long bridges where construction time for the final completion stage is tight.

A long viaduct can have a complete precast deck speedily placed with this method. The decks are positioned using either a large crane or purpose made gantry. A rate of construction of two spans per day is considered normal where a gantry system is in use, if this pace is maintained a one kilometer deck can be placed in three weeks.

However, if this method of construction is chosen it is imperative that the engineer has clearly organized the deck construction schedule. The speed of this method depends on the timely delivery of prefabricated decks, the engineer and deck contractor must set out a rate of construction which allows the supplier to produce a sufficient decks to time while the deck contractor must be ready to place and store decks on receipt of delivery.

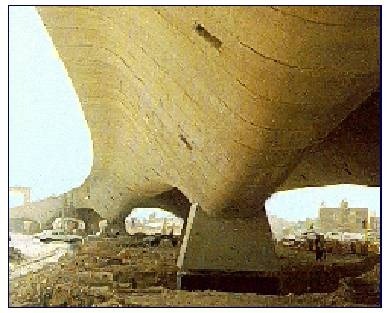

(iii) Precast segmental decks:

Precast segmental deck construction is used for long bridges where the deck depth is difficult for cast in situ construction. Box girder deck segments are generally used where the segment can be 2m or less deep, between 2.5m and 4m long carrying a deck upto 15m wide are generally used.

Where in-situ post-tensioning is favoured the segments can be prestressed either internally or externally. Internal tendons must be protected from moisture attack.

The repetitive nature of this method allows for a variety of modern placement techniques to be used, though balanced or free cantilever about a pier is a preferred choice. With this method a crane or self launching gantry system can place upto six segments per day.

The rate of construction for internally prestressed segments is considered to be a span per week. If externally prestressed tendons are used it should be feasible to complete three spans per week.

No comments:

Post a Comment