STRUCTURAL DESIGN PROCESS

The entire process of structural planning and design requires not only imagination and conceptual thinking but also sound knowledge of practical aspects, such as recent design codes and bye-laws, backed up by ample experience, institution and judgment.

It is emphasized that any structure to be constructed must satisfy the need efficiency for which it is intended and shall be durable for its desired life span. Thus, the design of any structure is categorizes into following two main types:-

1. Functional design

2. Structural design

FUNCTIONAL DESIGN:

The structure to be constructed should primarily serve the basic purpose for which it is to be used and must have a pleasing look.

The building should provide happy environment inside as well as outside. Therefore, the functional planning of a building must take into account the proper arrangements of room/halls to satisfy the need of the client, good ventilation, lighting, acoustics, unobstructed view in the case of community halls, cinema theatres, etc.

STRUCTURAL DESIGN:

Once the form of the structure is selected, the structural design process starts. Structural design is an art and science of understanding the behavior of structural members subjected to loads and designing them with economy and elegance to give a safe, serviceable and durable structure.

STAGES IN STRUCTURAL DESIGN:

The process of structural design involves the following stages.

1) Structural planning.

2) Action of forces and computation of loads.

3) Methods of analysis.

4) Member design.

5) Detailing, Drawing and Preparation of schedules.

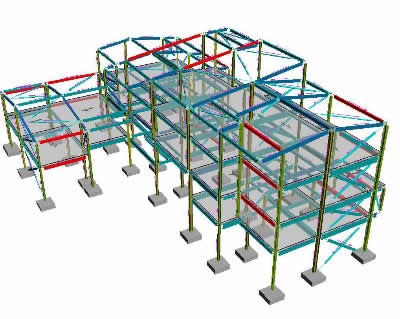

1. STRUCTURAL PLANNING:

After getting an architectural plan of the buildings, the structural planning of the building frame is done. This involves determination of the following.

a. Position and orientation of columns.

b. Positioning of beams.

c. Spanning of slabs.

d. Layouts of stairs.

e. Selecting proper type of footing.

1. Positioning and orientation of columns:Following are some of the building principles, which help in deciding the columns positions.

1. Columns should preferably be located at (or) near the corners of a building, and at the intersection of beams/walls.

2. Select the position of columns so as to reduce bending moments in beams.

3. Avoid larger spans of beams.

4. Avoid larger centre-to-centre distance between columns.

5. Columns on property line.

Orientation of columns:

1. Avoid projection of columns:

The projection of columns outside the wall in the room should be avoided as they not only give bad appearance but also obstruct the use of floor space, creating problems in placing furniture flush with the wall. The width of the column is required to be kept not less than 200mm to prevent the column from being slender. The spacing of the column should be considerably reduced so that the load on column on each floor is less and the necessity of large sections for columns does not arise.

2. Orient the column so that the depth of the column is contained in the major plane of bending or is perpendicular to the major axis of bending.

This is provided to increase moment of inertia and hence greater moment resisting capacity. It will also reduce Leff/d ratio resulting in increase in the load carrying capacity of the column.

2. POSITIONING OF BEAMS:

1. Beams shall normally be provided under the walls or below a heavy concentrated load to avoid these loads directly coming on slabs.

2. Avoid larger spacing of beams from deflection and cracking criteria. (The deflection varies directly with the cube of the span and inversely with the cube of the depth i.e. L3/D3. Consequently, increase in span L which results in greater deflection for larger span).

3. SPANNING OF SLABS:

This is decided by supporting arrangements. When the supports are only on opposite edges or only in one direction, then the slab acts as a one way supported slab. When the rectangular slab is supported along its four edges it acts as a one way slab when Ly/Lx < 2.

The two way action of slab not only depends on the aspect ratio but also on the ratio of reinforcement on the directions. In one way slab, main steel is provided along with short span only and the load is transferred to two opposite supports. The steel along the long span just acts as the distribution steel and is not designed for transferring the load but to distribute the load and to resist shrinkage and temperature stresses.

A slab is made to act as a one way slab spanning across the short span by providing main steel along the short span and only distribution steel along the long span. The provision of more steel in one direction increases the stiffness of the slab in that direction.

According to elastic theory, the distribution of load being proportional to stiffness in two orthogonal directions, major load is transferred along the stiffer short span and the slab behaves as one way. Since, the slab is also supported over the short edge there is a tendency of the load on the slab by the side of support to get transferred to the nearer support causing tension at top across this short supporting edge. Since, there does not exist any steel at top across this short edge in a one way slab interconnecting the slab and the side beam, cracks develop at the top along that edge. The cracks may run through the depth of the slab due to differential deflection between the slab and the supporting short edge beam/wall. Therefore, care should be taken to provide minimum steel at top across the short edge support to avoid this cracking.

A two way slab is generally economical compare to one way slab because steel along both the spans acts as main steel and transfers the load to all its four supports. The two way action is advantageous essentially for large spans (>3m) and for live loads (>3kN/m2). For short spans and light loads, steel required for two way slabs does not differ appreciably as compared to steel for two way slab because of the requirements of minimum steel.

FOOTING:

The type of footing depends upon the load carried by the column and the bearing capacity of the supporting soil. The soil under the foundation is more susceptible to large variations. Even under one small building the soil may vary from soft clay to a hard murum. The nature and properties of soil may change with season and weather, like swelling in wet weather. Increase in moisture content results in substantial loss of bearing capacity in case of certain soils which may lead to differential settlements. It is necessary to conduct the survey in the areas for soil properties. For framed structure, isolated column footings are normally preferred except in case of exists for great depths, pile foundations can be an appropriate choice. If columns are very closely spaced and bearing capacity of the soil is low, raft foundation can be an alternative solution. For a column on the boundary line, a combined footing or a raft footing may be provided.

ASSUMPTIONS

The following are the assumptions made in the earthquake resistant design of structures:

• Earthquake causes impulsive ground motions, which are complex and irregular in character, changing in period and amplitude each lasting for small duration. Therefore resonance of the type as visualized under steady-state sinusoidal excitations, will not occur as it would need time to build up such amplitudes.

• Earthquake is not likely to occur simultaneously with wind or max. Flood or max. sea waves.

• The value of elastic modulus of materials, wherever required, maybe taken as per static analysis.

No comments:

Post a Comment