Bamboo as a Building Material – its Uses and Advantages in Construction Works

Bamboo as a building material has high compressive strength and low weight has been one of the most used building material as support for concrete, especially in those locations where it is found in abundance.

Bamboo as a building material is used for the construction of scaffolding, bridges and structures, houses.

Due to a distinctive rhizome-dependent system, bamboos are one of the fastest-growing plants in the world and their growth is three times faster than most other species of plants. They are renewable and extremely versatile resource with multi-purpose usage. Among many uses of bamboo, Housing is one of the major areas applications especially in the wake of residential shortages around the globe.

Bamboo as a building material is conventionally associated with the region of Southeast Asia and South America where climate is best suitable for its cultivation. In many of the nations, bamboo is used to hold up suspension bridges or simply make places of dwelling.

Various Structural Shapes of Bamboo as a Building Material

Bamboos are treated in such a way that they assume desired shapes and structures while they grow:

- Squared cross-section can be obtained by compressing the growing stalk of bamboo within a square section.

- Arch shapes of bamboo can also be created by compressing the bamboo’s growth into the desired shape. This would cost lesser than it would to get the same form with normal timber.

- Curved and Flat shapes of bamboo are achieved through traditional techniques like applying heat and pressure.

Methods of Working on Bamboo

For a bamboo to be used as a building material, it must be worked on to create desired shape, bend and length to be used for structural or other purposes.

Following are the different works involved with use of bamboo:

- Splitting

- Shaping

- Bending

Splitting of Bamboo

The bamboo canes are split into halves or quarter sections using a knife ideal for the job and setting them apart by a wedge. About four or eight segments can be acquired which are used as canes, strips or battens. Canes can be peeled to make strings and ropes up to the age of 18 months.

Splitting of a bamboo cane

Splitting bamboo with a knife frame

Shaping of Bamboo

Even though bamboos are naturally circular in form but if they are grown in a box of square shape they acquire a shape as desired.

Bending of Bamboo

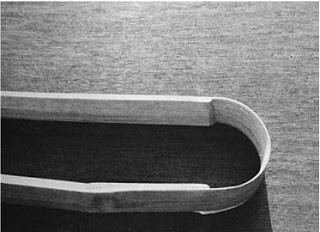

Bamboos can be bent while they are freshly cut by heating them above the temperature of 150° C. Bamboo will retain this shape even after cooling and drying off.

Bamboo being subjected to bending

Preservation of Bamboo

A thorough treatment of Bamboo is required to protect it against insects and rot before it is put into use. Commonly a mixture of Borax and Boric acid are utilized for this purpose. Another procedure generally employed is to boil cut bamboo to remove the starches that draw insects.

Bamboo as a Building Material

Utilization of Bamboo for construction is achieved by a structural frame technique which is related to same approach applied in usual timber frame design and construction.

In the case bamboo, floor, walls and roof are interconnected and often rely on the other for overall stability. Bamboo has played a vital role in the growth of enterprises and the rural transformation.

Bamboo for Foundations

There is very limited use of bamboo as foundation material because when in contact with moisture laden surface they decay fast. However, this issue can be tackled to quite an extent though proper treatment using appropriate chemicals.

The various types of foundations constructed with bamboo are:

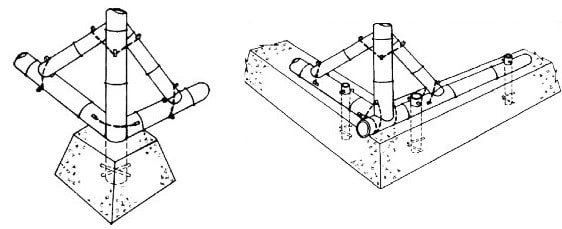

a) Bamboo which is in direct contact with ground surface.

b) Bamboo fixed to rock or preformed concrete footings

c) Composite bamboo or concrete columns

d) Bamboo piles

Bamboos are used in various shapes and forms to build foundation. Some of the common shapes of bamboos are:

a) Flattened bamboo shape which is acquired by splitting freshly cut bamboo stalks and then rolling and flattening them.

b) Bamboo mats as thin as 5-6mm or 10-15mm in size are woven according to design prerequisite. Phenolic resins are used in structures employing bamboo mats.

c) Bamboo plastic composite is a pioneering technology in which bamboo fiber as raw material is blended with plastic as the core material. These mats are highly resistant to moisture and structurally more stable.

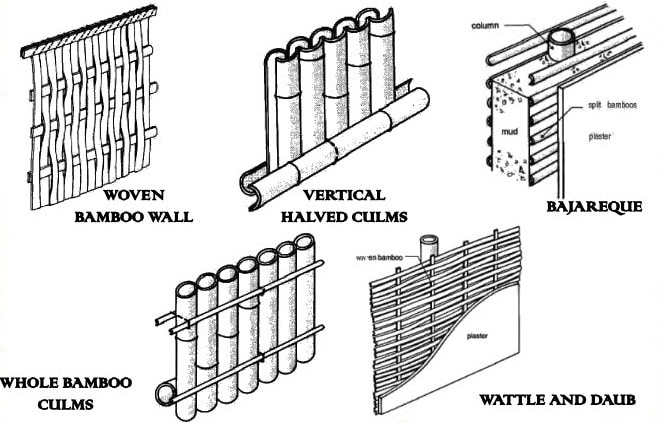

Walls Construction with Bamboo as a Building Material

Bamboo is extensively used for construction of walls and partitions. Posts and beams are the main elements normally constructed with bamboo provide structural framework for walls. They positioned in a way to be able to withstand forces of nature. An infill is used between framing elements to add strength and stability to the walls.

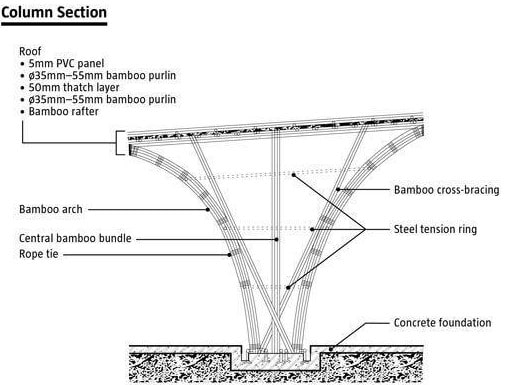

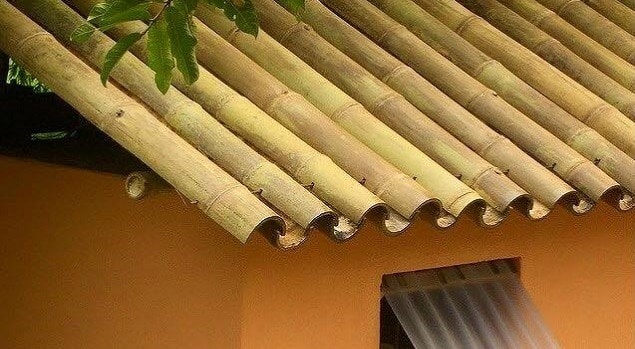

Roofing with Bamboo as a Building Material

Bamboo is one of the best roofing materials and provides ample sturdiness to the structure. It is a proven shield against forces of nature or animals and are considerably light weighted which makes them easy to install. The bamboo roofs encompass purlins, rafters and trusses.

Scaffolding with Bamboo as a Building Material

Due to advantageous properties of bearing heavy load bamboos are considered as one of the highly-endorsed materials for scaffolding even for tall structures.

For the construction of scaffolding, cane extensions are obtained by lashing cane ends using several ropes. The ties are positioned in such a way that forces acting vertically downwards lodge the nodes in the lashing.

This technique has immense significance since the joints can be re-aligned in the right degree.

Advantages of Bamboo as a Building Material

The various advantages of bamboo are as mentioned below:

- Tensile strength: Bamboo has higher tensile strength than steel because its fibers run axially.

- Fire Resistance: Capability of bamboo to resist fire is very high and it can withstand temperature up to 4000 C. This is due to the presence of high value of silicate acid and water.

- Elasticity: Bamboo is widely preferred in earthquake prone regions due to its elastic features.

- Weight of bamboo: Bamboos due to their low weight are easily displaced or installed making it very easier for transportation and construction.

- Unlike other building materials like cement and asbestos, bamboo poses no danger to health.

- They are cost effective and easy to use.

- They are especially in great demand in earthquake prone areas.

Disadvantages of Bamboo

Bamboos come with their own set of drawbacks such as:

- They require preservation

- Shrinkage: Bamboo shrinks much greater than any other type of timber especially when it loses water.

- Durability: Bamboo should be sufficiently treated against insect or fungus attack before being utilized for building purposes.

- Jointing: Despite prevalence of various techniques of jointing, structural reliability of bamboo is questionable.

No comments:

Post a Comment