Corrosion of Steel Reinforcement in Concrete -Causes and Protection

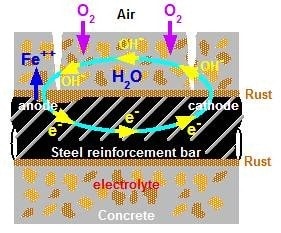

The corrosion of steel reinforcement in concrete is complex, but basically it is an electrochemical reaction similar to that of a simple battery. The composition of mild steel varies along its length and potential anodic (more negatively charged) and cathodic (positively charged) sites can be set up at various points.

From the days of yore when the great pyramids of Egypt or the Hanging Garden of Babylon, were constructed, mankind were in search of a construction material that can withstand the vagaries of nature, without any maintenance. In quest of such material, mankind ultimately found a wonder material ‘Portland Cement’.

For the last one and a half century, cement concrete has been extensively used for various structures which man could dream or conceive of with the misconception that they will last forever. Most of the failures or non functioning of the structure to its desired service condition is mainly attributed to the lack of understanding of the environmental condition and lack of proper, systematic and scientific maintenance.

Valuable assets of a country are created through construction. Construction plays a vital role in economic development. It is a forerunner activity and hallmark of development process of any nation.

Steel reinforcement which is used in RCC, though on one side complements the concrete for its weakness in tension (tensile stress), it also impairs the durability and longevity of concrete, due to its proneness to corrosion.

Repairs and rehabilitation of concrete structures, which of late has become an activity comparable to construction itself worldwide, is mostly because deterioration of concrete due to corrosion of embedded steel.

In the earlier part of this century when the Reinforced Concrete Construction began to be widely used, replacing almost completely the hitherto used construction materials viz. Timber, (stone) Masonry and steel sections etc., the life expectation of the R. C. structures was of the order of 100 years. However, at the turn of century we find these expectations belied and ironically newer constructions say 20 to 25 years old, show serious deterioration and distress.

The durability of concrete has become a highly discussed topic in global development. Even though several factors are responsible for early distress in reinforced concrete structures it is observed that in majority of cases, it is because of the corrosion of steel.

The corrosion seems to be an all-pervasive phenomenon causing widespread destruction of all types of structures in all countries across the world and has come to be termed as ‘Cancer’ for concrete.

Ideally speaking, a good concrete is supposed to provide adequate protection to the embedded steel. This is due to the protective alkaline environment (pH value as high as 12.5) provided by fresh concrete resulting in formation of protective coating on the surface of the steel, which passivates it from further corrosion.

However, over the passage of time, due to carbonation or ingress of chloride ions, pH value starts declining slowly and alkaline surrounding of the reinforcement bar is lost, heralding the corrosion process, which in turn causes cracks and spalling of concrete. It would thus be realized that the crucial factor giving quality and durability of concrete appears to be its impermeability, which can be ensured by providing sufficient cement content, low w/c ratio, complete compaction and curing. The same can be further improved by using proper admixtures and providing increased concrete cover.

However, these measures are firstly difficult to realize in practice fully and secondly the same are not found good enough in aggressive environment. Thus, it becomes necessary to provide additional protection to reinforcement steel, especially because of chloride induced corrosion (worse than carbonation corrosion) which can develop even in good quality concrete.

Most of the deterioration of RCC structures is mainly due to corrosion of reinforcement. Therefore, basic understanding of corrosion technology for both durability of structure and rehabilitation work is a must.

Steel embedded in hydrating cement paste rapidly forms a thin passivity layer of oxide which strongly adheres to the underlying steel and gives it complete protection from reaction with oxygen and water, that is from formation of rust or corrosion. This state of the steel is known as passivation.

Maintenance of passivation is conditional on an adequately high pH of the pore water in contact with the passivating layer. Thus, when the low pH front reaches the vicinity of the surface of the reinforcing steel, the protective oxide film is removed and corrosion can take place, provided oxygen and moisture necessary for the reactions of corrosion are present.

Causes of Corrosion of Steel Reinforcement in Concrete

Corrosion of steel in concrete is an electrochemical process. The electrochemical potentials to form the corrosion cells may be generated in two ways:

(a) Composition cells may be formed when two dissimilar metals are embedded in concrete, such as steel rebars and aluminum conduit pipes, or when significant variations exist in surface characteristics of the steel.

(b) Concentration cells may be formed due to differences in concentration of dissolved ions near steel, such as alkalies, chlorides, and oxygen.

The differences in electrochemical potential can arise from differences in the environment of the concrete. Electrochemical cells form also due to a variation in salt concentration in the pore water or due to a non-uniform access to oxygen.

Thus, one of the two metals (or some parts of the metal when only one metal is present) becomes anodic and the other cathodic. The fundamental chemical changes occurring at the anodic and cathodic areas are as follows.

When there exists a difference in electrical potential along the steel in concrete, an electrochemical cell is set up: there form anodic and cathodic regions, connected by the electrolyte in the form of the pore water in the hardened cement paste.

The positively charged ferrous ions Fe++ at the anode pass into solution while the negatively charged free electrons e– pass through the steel into the cathode where they are absorbed by the constituents of the electrolyte and combine with water and oxygen to form hydroxyl ions (OH)–. These travels through the electrolyte and combine with the ferrous ions to form ferric hydroxide which is converted by further oxidation to rust. The reactions involved are as follows:

Anodic reactions:

Fe -> Fe++ + 2e–

Fe++ + 2(OH)– -> Fe(OH)2 (ferrous hydroxide)

4Fe(OH)2 + 2H2O + O2 -> 4Fe(OH)3 (ferric hydroxide)

(Water) (Air) 2Fe(OH)3 -> Fe2 × O3 × H2O + 2H2O — Hydrated ferric oxide (rust).

Cathodic reaction:

4e– + O2 + 2H2O -> 4(OH)–

It can be seen that oxygen is consumed and water is regenerated but it is needed for the process to continue. Thus, there is no corrosion in, dry concrete, probably below a relative humidity of 60 percent; nor is there corrosion in concrete fully immersed in water, except when water can entrain air, for example by wave action.

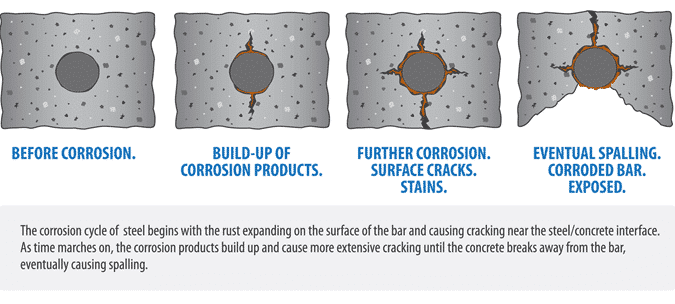

The transformation of metallic iron to rust is accompanied by an increase in volume, which depending on the state of oxidation, may be as large as 600 percent of the original metal. This volume increase is believed to be the principal cause of concrete expansion and cracking. It should be noted that the anodic reaction involving ionization of metallic iron will not progress far unless the electron flow to the cathode is maintained by consumption of the electrons at the cathode; for this the presence of both air and water at the surface of the cathode is absolutely necessary.

In the absence of chloride ions in the solution, the protective film on steel is reported to be stable if the pH of the solution stays above 11.5. Normally there is sufficient alkalinity in the system to maintain the pH above 12. In exceptional conditions (e.g., when concrete has high permeability and alkalies and most of the calcium hydroxide are either carbonated or neutralized by an acidic solution), the pH of concrete near steel may be reduced to less than 11.5, thus destroying the passivity of steel and setting the stage for the corrosion process.

In the presence of chloride ions, depending on the C1– / OH– ratio, it is reported that the protective film may be destroyed even at pH values considerably above 11.5.

For corrosion to be initiated, the passivity layer must be penetrated. Chloride ions activate the surface of the steel to form an anode, the passivated surface being the cathode. The reactions involved are as follows:

Fe++ + 2Cl– -> FeCl2

FeCl2 + 2H2O -> Fe(OH)2 + 2HCl

Carbonation of Embedded Steel

It is recognized that steel embedded in a heavily alkaline medium with pH values from 9 upwards will not rust. During the setting of concrete, cement begins to hydrate, this chemical reaction between cement and water in the concrete causes calcium hydroxide to be formed from the cement clinker. This ensures the concrete’s alkalinity, producing a pH value of more than 12.6 which renders the steel surface passive.

Protection of the reinforcement from corrosion is thus provided by the alkalinity of the concrete, which leads to passivation of the steel. The reserve of calcium hydroxide is very high, so there is no need to expect steel corrosion even when water penetrates to the reinforcement of the concrete. because of this, even the occurrence of small cracks (up to 0.1 mm in width) or blemishes in the concrete need not necessarily lead to damage.

Fig: Carbonation leads to the general corrosion along the full length of the bar.

The above figure shows the first outward signs of general corrosion taking place is surface cracking of the concrete along the line of the steel.

The above fig. shows that as the corrosion proceeds, the concrete will spall away completely to expose the steel.

Environmental influences and carbon dioxide in particular, will reduce the concrete’s pH value (carbonation) and thus removed the passivating effect, in conjunction with existing humidity, the result is corrosion of the reinforcement.

Carbonation is the effect of CO2 from the atmosphere reacting with alkaline component in concrete Ca(OH)2 in the presence of moisture thereby converting the calcium hydroxide to CaCO3. The calcium carbonate is slightly soluble in water.

The pH value of the pore water is generally between 12.5 to 13.5 but due to carbonation the pH is reduced to less than 9. The reinforcement therefore is no longer in the passivating range and corrosion occurs. The corrosion is accelerated in the presence of further moisture and oxygen.

Ca(OH)2 + CO2 + H2O = CaCO3 + 2 H2O

The process of carbonation reaches the depth of cover.

The factors influencing the depth of carbonation are:

- Depth of cover

- Permeability of concrete

- Grade of concrete

- Time

- Whether the concrete is protected or unprotected

- The environmental influences.

The ultimate result cracking, spalling and corrosion.

Chlorides

Chlorides are generally acidic in nature and can come from a number of different sources, the most common being, de-icing salts, use of unwashed marine aggregates, sea water spray, and certain accelerating admixtures (their use is now prohibited).

In the presence of chlorides localized pitting corrosion occurs which does not always have associated with it the early warning signs of surface cracking.

Chlorides induced corrosion is potentially more dangerous than that resulting from carbonation. Like most of the aspects of concrete durability, deterioration due to corrosion of the reinforcement can take place years (5 to 20) to manifest itself.

Factors Influencing Corrosion of Steel Reinforcement

The factors which generally influence corrosion of reinforcement in RC structures are:

- pH value,

- Moisture,

- Oxygen,

- Carbonation,

- Chlorides,

- Ambient temperature and relative humidity,

- Severity of exposure,

- Quality of construction materials,

- Quality of concrete,

- Cover to the reinforcement,

- Initial curing conditions, and

- Formation of cracks.

Damages to Concrete Due to Corrosion of Steel Reinforcement

The process of corrosion, once set off, results in deterioration and distress of the RC member. The various stages of destruction are as follows:

Stage 1: Formation of white patches

If the reinforcement is embedded in a concrete which is pervious enough to allow the passage of water and carbon dioxide then carbonation advances from surface to interior concrete. Carbon dioxide reacts with calcium hydroxide in the cement paste to form calcium carbonate. The free movement of water carries the unstable calcium carbonates towards the surface and forms white patches. The white patches at the concrete surface indicates the occurrence of carbonation.

Stage 2: Brown patches along reinforcement

When reinforcement starts corroding, a layer of ferric oxide is formed on the reinforcement surface. This brown product resulting from corrosion may permeate along with moisture to the concrete surface without cracking of the concrete. Usually it accompanies cracking or cracking of the concrete occurs shortly thereafter.

Stage 3: Occurrence of cracks

The products of corrosion normally occupy a much greater volume about 6 to 10 times than the parent metal. The increase in volume exerts considerable bursting pressure on the surrounding concrete resulting in cracking.

The hair line crack in the concrete surface lying directly above the reinforcement and running parallel to it is the positive visible indication that reinforcement is corroding. These cracks indicate that the expanding rust has grown enough to split the concrete. Even at this stage the reinforcement looks as though it is rust free if the concrete is chipped off.

Stage 4: Formation of multiple cracks

As corrosion progresses, there will be formation of multiple layers of ferric oxide on the reinforcement which in turn exert considerable pressure on the surrounding concrete resulting in widening of hair cracks. In addition, several new hair cracks are also formed. The bond between concrete and the reinforcement is considerably reduced. There will be a hollow sound when the concrete is tapped at the surface with a light hammer.

Stage 5: Spalling of cover concrete

Due to loss in bond between steel and concrete and formation of multiple layers of scales, the cover concrete starts peeling off. At this stage, there is considerable reduction of the size of the bar.

Stage 6: Snapping of bars

The continued reduction in the size of bars, results in snapping of the bars. Usually snapping occurs in ties / stirrups first. At this stage, there will also be a considerable reduction in the size of the main bars.

Stage 7: Buckling of bars and bulging of concrete

The spalling of the cover concrete and snapping of ties (in compression member) causes the main bars to buckle, thus resulting in the bulging of concrete in that region. This follows a collapse of the structure.

Minimizing the Risk of Steel Reinforcement Corrosion

The quality and depth of concrete in the cover zone are all important in minimizing the risk of corrosion as shown in fig. below.

Quality of Concrete

Quality is controlled largely by minimizing permeability.

Depth of Reinforcement Steel Cover

Recommendations for minimum depths of cover are given in the codes of practice and are based on exposure conditions and minimum cement contents. Higher cement contents infer lower water cement rations leading to permitted reductions in cover.

At no time should the normal cover be less than the maximum size of aggregates+5mm.

Materials of Concrete Construction

Blended cements made from combinations of PC/PFA and PC/GGBS can lead to significant reduction in chloride penetration. However, in situations where these materials are not cured properly there is a risk of increased carbonation. Care must be taken that all aggregates and admixtures contain limited amount of chlorides.

No comments:

Post a Comment