Underground Surveying Methods and Applications

What is Underground Surveying?

Underground surveying embraces the survey operations performed beneath the surface of the earth in connection with tunneling, exploration and construction in subterranean passageways. It is quite different from surveying on the surface.

The following peculiarities of underground surveys indicate how they differ from surface surveys:

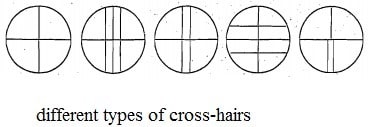

- Artificial illumination is required to view instrument crosshairs, to read verniers, to sight targets etc. Because of poor lighting.

- Working space in passageways is often cramped.

- Instrument stations and benchmarks for levelling must often be set into the roof of a passageway to minimize disturbance from the operations being carried on in the workings.

- Instrument stations are set with some difficulty since plugs must be driven into drill holes in rock.

- In many instances the underground workings arc wet, with considerable water dripping from the roofs of passage ways and running along the floors.

Applications of Underground Surveys

The major application of underground surveysis in the construction of tunnels and other underground utilities. The tunnel is constructed when open excavation becomes uneconomical usually when it is more than 20 m. It

- Reduces the grade

- Shortens the distance between given points separated by a dividing mountain or ridge.

- Meets the demand of-modern rapid transit in a city.

- Engineering operations to be performed

- Exact alignment

- Proper gradient

- Establishment of permanent stations marking the proposed route.

The survey work in connection with tunneling can be divided into:

- Surface survey

- Transferring the alignment underground

- Levels in tunnels

Surface survey:

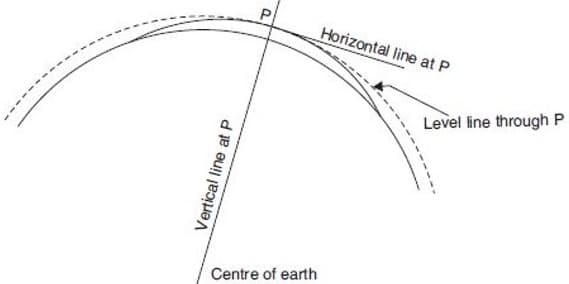

Surface survey connects points representing each portal of a tunnel. A traverse connecting the portal points determines the azimuth, distance and differences in elevation of each end of the proposed tunnel. Based on the local conditions and proposed length of the tunnel the methods of working are adopted.

It is always advisable that the survey is based on the suitable local coordinate system. The alignment is permanently referenced by a system of monuments within an area outside each tunnel portal. And here is sketch regarding how the tunneling work proceeds.

Central line and grade stakes within the tunnel are usually set in the roof to avoid displacement and destruction by the constant flow of people and machinery as construction proceeds. If the stakes are set on the floor they should be offset into an area along the tunnel’s edge.

Transferring the alignment underground

For long tunnel excavation is carried inward from both parties. But vertical shafts are also sunk up to the required depth along the alignment of the tunnel at intermediate locations along the routes. The vertical alignment can be done by

- Plumb bob

- Optical collimator

- Laser

A heavy plumb bob (5 to 10 kg) is suspended on either a wire of heavy twine. Oscillations of the bob can be controlled by suspending it in a pot with high viscosity oil. The bob is suspended from a removable bracket attached to the surface side of the shaft.

Optical plumbing becomes important with the increase in depth of internal shaft. Various types of plummet are available for upwards and downward sighting to allow the establishment of a vertical line and these are normally manufactured so as to be interchangeable with theodolites on their tripods.

As the line of sight of a theodolite in adjustment will transit in a vertical plane, it can also be used to check perpendicularity.

The advantages of an optical collimator are:

- More convenient than a plumb bob.

- Can be used to set marks directly on the floor of a completed shaft

- No wires as in case of plumb bob.

A laser equipment can be, used to, provide a vertical line of sight. The laser generates a light beam of high intensity and of low angular divergence and can be projected over long distances since the spread of the beam is very small to provide a visible line for constant reference

Levels in tunnels:

In transferring levels underground, little difficulty is encountered at the ends of the tunnel, but at the shaft use is made of

- Steel tape

- Chain

- Constructed rods

- Steel wires

Now a days EDMI is also used. But in all cases the main idea is to deduct the height of the shaft measured from the top of a benchmark of known value.

Figure showing how the depth is measured by steel tape

Figure showing Depth measured by EDM

The important features of EDM are:

- EDMI unit and reflectors should be in the same vertical line.

- Both are mounted on stable support.

- Visibility should be good for EDMI to operate.