14 Uses of Sedimentary Rocks in Civil Engineering

Uses of sedimentary rock can be found in almost all buildings and public structures. This makes it substantially important construction material in civil engineering projects.

The sedimentary rock is formed by the settlement and subsequent cementation of mineral or organic particles on the floor of oceans or other collections of water. The application of sedimentary rock in civil engineering is discussed.

Types of sedimentary rocks

There are number of sedimentary rock types. These are provided so as to discuss uses of sedimentary rocks based on its types.

- Clastic sedimentary rocks

- Conglomerates and breccias

- Sandstones includes Quartz , Feldspathic, Lithic,”Clean” sandstones, Muddy sandstones

- Biochemical sedimentary rocks

- Limestone; coreals, mollusks, foraminifera, and coal

- Chemical sedimentary rocks

- Pyroclastic flows, impact breccias, and volcanic breccias

Uses of Sedimentary Rocks

There are many uses of sedimentary rocks in civil engineering. The main applications of this type of rock is provided below:1. Building Construction

Sandstone

- Sandstone, which is easy to work with, has been broadly utilized in the construction of buildings specifically in areas where large quantity of sandstone is available.

- For example, The Cliffe Castle Museum in England is composed completely of sandstone. In addition to Red Fort building stone in India.

- Marble is also used mainly in building construction.

- Famous marble buildings are Taj Mahal in India ,the leaning tower of Pisa in Italy, the Parthenon in Greece

Limestone

Limestone has been used in several important building constructions for instance monuments.

Fig. 1: Redfort building in India, Sandstone application in building construction

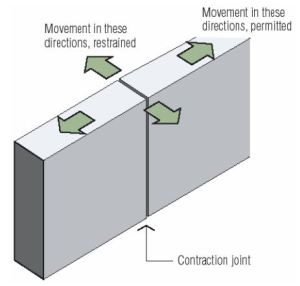

Fig. 2: Cliffe castle museum in England 2. Structural Wall Construction

Both sandstone and limestone are suitable for the construction of structural walls. Nonetheless, sandstone shall be considered carefully because it might be excessively porous and fragile for load bearing structures.

Fig. 3: Wall constructed from sandstone 3. Cement Production

- Limestone is the main source material for the production of Portland cement.

- Shale is used as a component in cement production

Fig. 4: Limestone hauled for cement production 4. Concrete Production

Sedimentary rock used as aggregate in concrete production to withstand pressure.

Fig. 5: Limestone aggregate for concrete production 5. Pavement and Road Construction

- Sandstone and limestone have been used for the construction of pavement stone and road stone.

- Shale is used as aggregate in road construction

- Sedimentary rocks are used in highway roadbed.

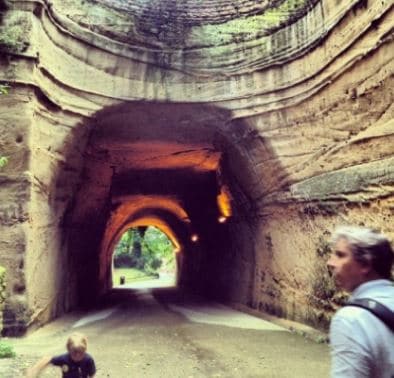

Fig. 6: Road stone 6. Tunneling

- Sandstone is suitable type of rock for tunneling especially thick bedded, well cemented, and siliceous or ferruginous sandstone.

- It is strong and easily workable

- Lining is not needed

- Sandstone does not influence geological structures and ground condition detrimentally.

- Tunneling is easily progressed in shale formation due to its softness, but proper lining shall be provided.

Fig. 7: Tunneling work, sedimentary rock 7. Brick and Tile Manufacturing

Shale is used as one components of materials used in the construction of bricks and tiles.

Fig. 8: Tile manufactured from limestone 8. Architectural and Monumental Stone

- There are certain types of sedimentary rock that can be used as a architectural and monumental stone for example Portland stone (a white -grey limestone).

- It can withstand weathering affects adequately. More importantly,Portland stone can be cut and craved comfortably by masons which is a crucial advantage. That is why it is one of the most favored architectural and monumental stone.

- Portland stone has been used in the construction of St. Paul’s Cathedral, Buckingham Palace, Westminster palace, British Museum, the Bank of England.

Fig. 9: Buckingham palace 9. Building Interior Decoration

Marble is recrystallized and then used for decoration of building interior. It is also used for statues , table surfaces and novelties.

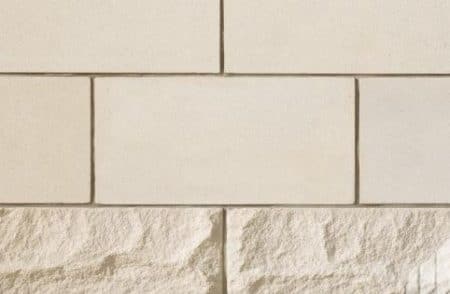

Fig. 10: Sandstone 10. Façade Construction

- Portland stone can be used for the construction of facades of reinforced concrete buildings.

- Conglomerate used in decoration

Fig. 11: Exterior wall decoration 11. Filler in Paint

Shale which is a type of sedimentary rock that can be employed as a filler in many paints12. Sheetrock and Plaster

Gypsum is a major ingredient in sheetrock and plaster.13. Wallboard

Gypsum is ground up and employed for the production of wallboard.14. Others

Sedimentary rocks are used in the construction of earthen dam, railroad ballast, canals, and as a rock fill.

Fig. 12: Rail road ballast - Clastic sedimentary rocks