Types of Bonds in Brick Masonry Wall Construction and their Uses

Types of bonds in brick masonry wall construction are classified based on laying and bonding style of bricks in walls. The bonds in brick masonry is developed by the mortar filling between layers of bricks and in grooves when bricks are laid adjacent to each other and in layers in walls.

Mostly used material for bonds in brick masonry is cement mortar. Lime mortar and mud mortar are also used.

Types of Bonds in Brick Masonry Wall Construction :

The most commonly used types of bonds in brick masonry are:

- Stretcher bond

- Header bond

- English bond and

- Flemish bond

Other Types of bonds are:

- Facing bond

- Dutch bond

- English cross bond

- Brick on edge bond

- Raking bond

- Zigzag bond

- Garden wall bond

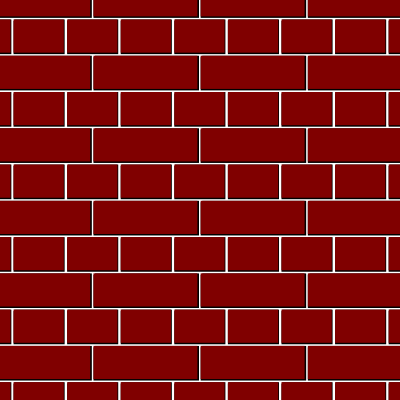

1. Stretcher bond

Longer narrow face of the brick is called as stretcher as shown in the elevation of figure below. Stretcher bond, also called as running bond, is created when bricks are laid with only their stretchers showing, overlapping midway with the courses of bricks below and above.

Stretche bond in the brick is the simplest repeating pattern. But the limitation of stretcher bond is that it cannot make effective bonding with adjacent bricks in full width thick brick walls. They are suitably used only for one-half brick thick walls such as for the construction half brick thick partition wall.

Walls constructed with stretcher bonds are not stable enough to stand alone in case of longer span and height. Thus they Then need supporting structure such as brick masonry columns at regular intervals.

Stretcher bonds are commonly used in the steel or reinforced concrete framed structures as the outer facing. These are also used as the outer facing of cavity walls. Other common applications of such walls are the boundary walls, gardens etc.

Fig-1: Stretcher Bond

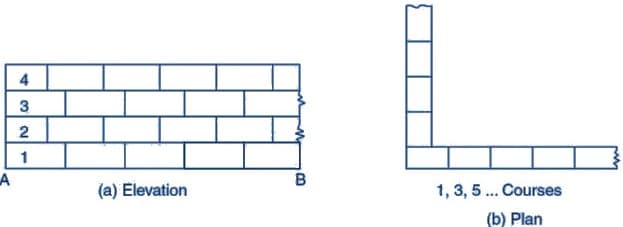

2. Header bond

Header is the shorter square face of the brick which measures 9cm x 9cm. Header bond is also known as heading bond. In header bonds, all bricks in each course are placed as headers on the faces of the walls. While Stretcher bond is used for the construction of walls of half brick thickness whereas header bond is used for the construction of walls with full brick thickness which measures 18cm. In header bonds, the overlap is kept equal to half width of the brick. To achieve this, three quarter brick bats are used in alternate courses as quoins.

Fig-2: Header Bond

Fig-3: Header Bond Isometric View

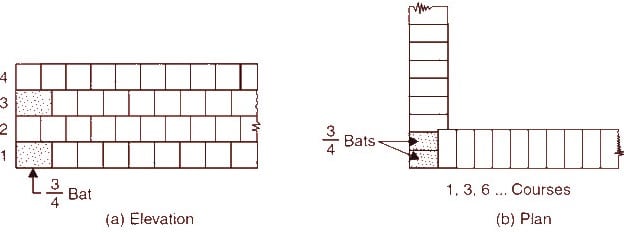

3. English Bond

English bond in brick masonry has one course of stretcher only and a course of header above it, i.e. it has two alternating courses of stretchers and headers. Headers are laid centered on the stretchers in course below and each alternate row is vertically aligned.

To break the continuity of vertical joints, quoin closer is used in the beginning and end of a wall after first header. A quoin close is a brick cut lengthwise into two halves and used at corners in brick walls.

Fig-4: English Bond

Fig-4: English Bond – Isometric View

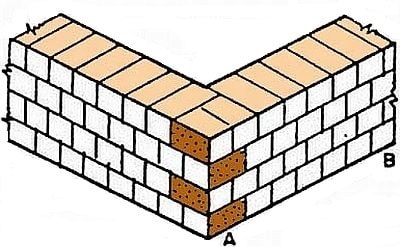

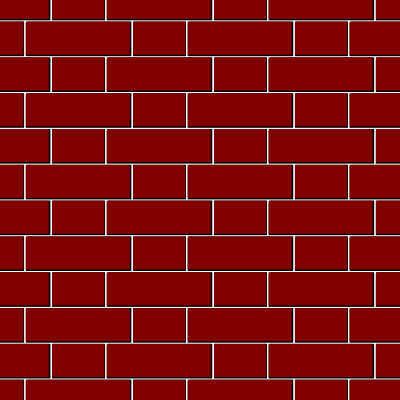

4. Flemish Bond

For the breaking of vertical joints in the successive courses, closers are inserted in alternate courses next to the quoin header. In walls having their thickness equal to odd number of half bricks, bats are essentially used to achieve the bond.

Flemish bond, also known as Dutch bond, is created by laying alternate headers and stretchers in a single course. The next course of brick is laid such that header lies in the middle of the stretcher in the course below, i.e. the alternate headers of each course are centered on the stretcher of course below. Every alternate course of Flemish bond starts with header at the corner.

The thickness of Flemish bond is minimum one full brick. The disadvantage of using Flemish bond is that construction of Flemish bond is difficult and requires greater skill to lay it properly as all vertical mortar joints need to be aligned vertically for best effects. For the breaking of vertical joints in the successive courses, closers are inserted in alternate courses next to the quoin header. In walls having their thickness equal to odd number of half bricks, bats are used to achieve the bond.

Flemish bonds have better appearance but are weaker than English bonds for load bearing wall construction. Thus, if the pointing has to be done for brick masonry walls, then Flemish bond may be used for better aesthetic view. If the walls have to be plastered, then it is better to use English bond.

Fig-5: Flemish Bond

Fig-6: Flemish Bond Front Appearance

Flemish bonds are classified as:

- Single Flemish Bond

- Double Flemish Bond

Single Flemish bond is a combination of English bond and Flemish bond. In this type of construction, the front exposed surface of wall consists of Flemish bond and the back surface of the wall consists of English bond in each course. Minimum thickness required for single Flemish bond is one and a half brick thickness. The main purpose of using single Flemish bond is to provide greater aesthetic appearance on the front surface with required strength in the brickwork with English bond.

Double Flemish Bond has the same appearance both in the front and back elevations, i.e. each course consists of alternate header and stretcher. This type of bonding is comparatively weaker than English bond.