Methods to Reduce Efflorescence in Newly Constructed Masonry Walls

Several methods and techniques are available

to reduce the efflorescence in newly constructed masonry walls. Efflorescence reduction systems should be thoroughly executed otherwise the required result will not be achieved.

Satisfactoy implementation of these methods requires extensive knowledge and adequate understanding of each system. Therefore, this article will explore various methods used to decrease potential efflorescence on bricks.

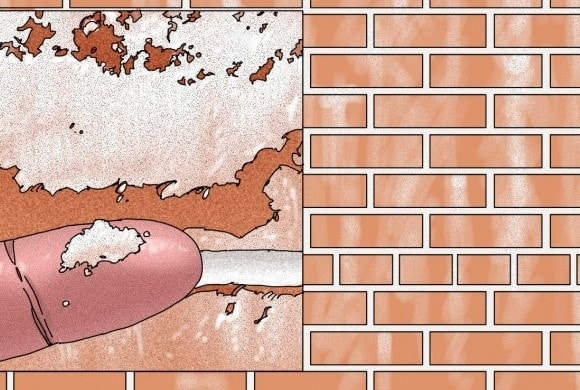

Fig.1: Efflorescence on Brick Masonry Walls

Methods to Reduce Efflorescence in Newly Constructed Masonry Walls

Reduction methods for Potential efflorescence in newly constructed masonry walls are as follow:

- Reduction of water penetration into masonry wall

- Expelling Penetrated or condensed water out of masonry wall quickly

- Prevent the contact between bricks which are different in chemicals composition

- Reduce quantity of efflorescence compounds in materials of masonry wall

Reduction of Water Penetration Especially Wind Driven Rain Water into Masonry Wall

There are several measures which can be used during the construction of masonry walls to decrease water that may ingress the wall. These measures are as follow:

- Form a good bond between masonry units and mortar: A satisfactory bond between masonry units can be obtained if certain construction measures are considered while masonry wall are constructed.

- For example, utilizing mortar compatible with masonry units, fill both bed and head mortar joints sufficiently when solid units are used, adequately fill bed and face shell joints if hollow masonry units are used, consolidate mortar joint from ousted face of the wall.

- Take necessary measures to avoid water penetration, especially rain, into partially constructed walls and wall opening

- Movement joints in the masonry wall should be designed, placed and filled in the best possible way.

- Seal masonry wall-roof interface using flashing.

- Protect masonry wall from rain water by building overhangs.

- It is advised to either add suitable water repellent admixture to concrete masonry units or applying water repellent coating to the concrete masonry wall.

- Masonry building components such as chimney cops, sills and copings should be constructed from solid masonry units, reinforced concrete, corrosion resistant metals or stone.

These components should be extended and exceed masonry wall face by 2.5cm and flashings and weep holes should be provided.

It is recommended to slope (preferably 1:4) these components and attached to the masonry walls. Not only does the movement joints should be properly sized and positioned but also sealed sufficiently.

Expelling Penetrated or Condensed Water Out of Masonry Wall Quickly

Penetrated and condensed water in masonry wall can be discharged by considering the following techniques:

- Installing sound and durable weep holes and flashing at critical location of the masonry wall such as below window copings and sills, above lintels, masonry wall openings, roof-wall intersection and above ground level at the base of the wall.

- Another way to quickly drain water out of masonry wall is through drainage placed in the air space of the drainage wall.

Fig.2: Masonry Wall Drainage System

Prevent the Contact Between Bricks which are Different in Chemicals Composition

Contacts between different bricks in masonry wall can be prevented as follows:

- Install separator between different materials of masonry walls.

- Provide flashing or separator between masonry wall and other structural elements build from different materials for instance chimney caps, sills, and copings.

- If cavity wall is constructed, it is necessary to provide at least 5cm between exterior masonry Wythe and interior wall constructed form different materials.

Reduce Quantity of Efflorescence Compounds in Materials of Masonry Wall

The reduction of efflorescence compounds in materials of masonry walls can be obtained through the following approaches:

- Materials used on the construction of masonry walls such as masonry materials, water, admixtures and cleaning agents are recommended to be tested prior to the masonry wall construction.

- The results of materials tests in combination with construction methods need to be estimated to find out their combine effect on the efflorescence in the future.

- Masonry materials should be stored properly to prevent materials from moisture and contact with dissimilar materials otherwise the likelihood of efflorescence would increase.

- Protect masonry construction materials during delivery to avoid contamination

- If newly constructed masonry walls are cleaned, it is necessary to apply appropriate materials and procedure.

No comments:

Post a Comment