Different Types of Beams

A Beam is a structural element that primarily resist loads applied laterally to the beam's axis. It's is mode of deflection is primarily by bending. The loads applied to the beam result in reaction forces at the beam's support points. The total effect of all the forces acting on the beam is to produce the shear forces and bending moment within the beam, that in turn induce internal stresses, strains and deflections of the beam. Beams are characterized by their manner of support, profile(shape of cross section), length and material.

Different types of beams are used in the construction of buildings and structures. These are horizontal structural elements that withstand vertical loads, shear forces, and bending moments. Beams transfer loads that imposed along their length to their endpoints such as walls, columns, foundations, etc.

1. Simply supported beam

2. Fixed beam

3. Cantilever beam

4. Continuous beam

Types of Beams in Constructions

There are different types of beams which are classified based on the following conditions

- Based on Support Conditions

- Based on Construction Materials

- Based on Cross-Section Shapes

- Based on Geometry

- Based on Equilibrium Condition

- Based on Method of Construction

Based on Support Conditions

1. Simply Supported Beam

It is one of the simplest structural elements that both ends rest on supports but is free to rotate. It contains pinned support at one end and a roller support at the other end. Based on the assigned load, it sustains shearing and bending.

2. Fixed Beam

It is supported at both ends and fixed to resist rotation. It is also called a built-in beam. The fixed ends produce moments other than the reactions.

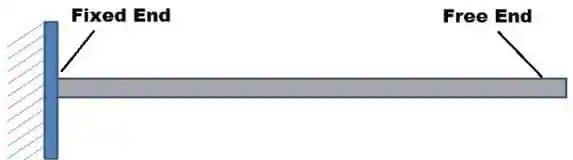

3. Cantilever Beam

If a beam is fixed at one end and set to be free at the other end, it is termed as a cantilever beam. The beam distributes the load back to the support where it is forced against a moment and shear stress. Cantilever beams allow the creation of a bay window, balconies, and some bridges.

4. Continuous Beam

A continuous beam has more than two supports distributed along its entire length.

Based on Construction Materials

It is constructed from concrete and reinforcement as shown in Fig. 5. Sometimes reinforced concrete beam is concealed in reinforced concrete slabs and it is called hidden beam or concealed beam

6. Steel Beams

It is constructed from steels and used in several applications.

7. Timber beams

The timber beam is constructed from timber and used in the past. However, The application of such a beam in the construction industry is significantly declined now.

Composite beams are constructed from two or more different types of materials, such as steel and concrete. Fig. 8 shows Different valid cross-sections for the composite beam.

Based on Cross-Section Shapes

Several cross-sectional shapes of beams are available and used in different parts of structures. These beams can be constructed from reinforced concrete, steel, or composite materials:

Reinforced concrete cross sectional shapes include:

This type of beam is widely used in the construction of reinforced concrete buildings and other structures.

10. T-section beam

This type of beam is mostly constructed monolithically with a reinforced concrete slab. Sometimes, Isolated T-beam is built to increase the compression strength of concrete.

Added to that, inverted T-beam can also be constructed according to the requirements of loading imposed.

11. L-section beam

This type of beam is constructed monolithically with a reinforced concrete slab at the perimeter of the structure, as illustrated in Fig

Steel cross sectional shapes include:

There are various steel beam cross-sectional shapes. Each cross-sectional shape offer superior advantages in a given condition compare with other shapes.

Square, rectangular, circular, I-shaped, T-shaped, H-shaped, C-shaped, and tubular are examples of beam cross-sectional shapes constructed from steel.

Based on Geometry

12. Straight beam

Beam with a straight profile and the majority of beams in structures are straight beams.

13. Curved beam

Beam with curved profile, such as in the case of circular buildings.

14. Tapered beam

Beam with tapered cross section.

5. Based on Equilibrium Condition

15. Statically Determinate Beam

For a statically determinate beam, equilibrium conditions alone can be used to solve reactions. The number of unknown reactions is equal to the number of equations.

16. Statically indeterminate beam

For a statically indeterminate beam, equilibrium conditions are not enough to solve reactions. So, the analysis of this type of beam is more complicated than that of statically determinate beams.

Based on Method of Construction

17. Cast In-situ Concrete Beam

This type of beam is constructed on the project site. So, forms are initially fixed, then fresh concrete is poured and allowed to hardened. Then, loads would be imposed.

This type of beam is manufactured in factories. So, the construction condition is more controllable compare with on-site construction. Consequently, the quality of the concrete of the beam would be greater.

Various cross-sectional shapes can be manufactures such as T- beam, Double T-beam, Inverted T-beam, and many more.

The pre-stressed concrete beam is constructed by stressing strands before applying loads on the beam. Pre-tensioned concrete beam and post-tensioned concrete beams are variations of pre-stressed concrete beam.

20. Deep Beam

A deep beam has considerable depth, as shown in Fig. 21, and its clear span to depth ratio is less than four, as per ACI Code. A substantial load is carried to the supports by a compression force combining the load and the reaction. Consequently, the strain distribution is no longer considered linear, as in the case of conventional beams.

21. Girder

Beams that take heavy loads, generally steel sections are used.