Types of Floors Systems for Multi-Storey Steel Structure Construction

What are the common types of floors systems used in the construction of multi storey steel structure?

Types of floor system used in the construction of multi storey steel structures with span ranges, advantages and criteria considered while floor system is specified for a given structure are discussed.

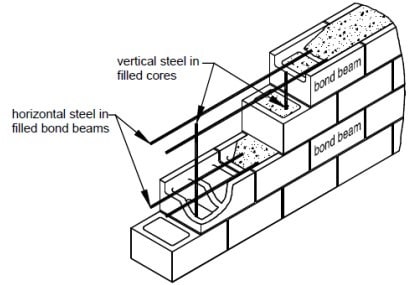

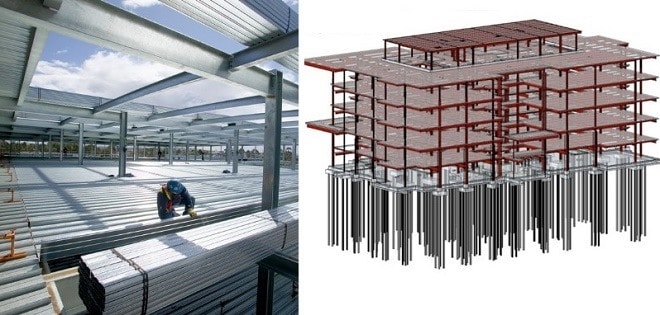

Fig.1: Floor System of Multi Storey Steel Structure

Types of Floors Systems Used for Multi-Storey Steel Structure Construction

Different types of floor system used for steel structures include:

- Short-span composite beams and composite slabs with metal decking

- Slimdek floor system

- Cellular composite beams with composite slabs and steel decking

- Slimflor beams with precast concrete units

- Long-span composite beams and composite slabs with metal decking

- Composite beams with precast concrete units

- Non-composite beams with precast concrete units

Short-Span Composite Beams and Composite Slabs with Metal Decking

As it may be observed from Figure 2, the components of such system consist of steel beam with shear studs fixed on its top flange that create a composite action between the beam and composite slab.

Fig.2: Composite Floor System

The slab consists of steel profile on which in situ concrete are poured. Various steel deck profiles are available and their span ranges are from 3m to 4m.

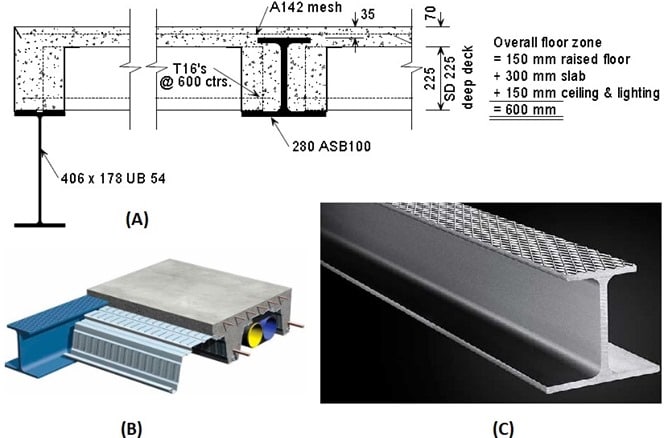

Fig.3: Different Steel Deck Profiles

Moreover, both primary and secondary beams are designed as composite member whereas edge beams could be designed as non-composite element.

The thickness of the beams ranges from 0.9 m to 1.2m; slab thickness is 130mm and steel deck depth is about 60mm. The span of primary beams varies between 6m and 9m and secondary beam span ranges from 6m to 7.5m.

It should be known that services and utilities are run under the slab, so it affects the overall thickness of the slab. Due to the fact that edge beams are mostly deeper than interior beams, therefore the thickness of floor system is controlled by edge beams.

Common advantages of this floor system are cost effective, light weight and requires thinner beams compared with non-composite floor systems.

As far as composite floor disadvantages are concerned, beams need fire protection, large numbers of columns are needed, greater floor thickness compared with other systems.

Slimdek Floor System

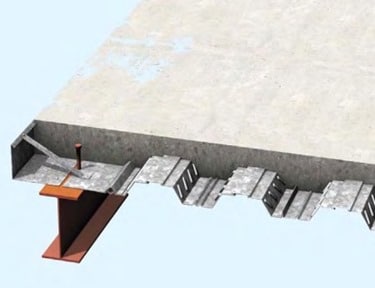

Details of slimdek floor systems are provided in Figure-4. It is composed of asymmetric steel beam that carry a slab with 225mm thickness.

The overall floor thickness is between 500mm to 1200mm. The span of slimdek floor system ranges from 6.5m to 7.5m.

The most outstanding advantages of slimdek floor system is that it provides almost a leveled soffit which simplify utility installation and the thickness of the floor is smaller compared with other systems. Consequently, the total height of the structure can be decreased.

There are certain disadvantages that associated with slimdek floor system. For example, special connection detailing would be required due to the difference between top and bottom flange width. The weight of steel is commonly larger in comparison with other floor systems.

Fig.4: Slimdek floor system; (A) details of beams, reinforcement and thickness, (B) 3D view of Slimdek floor system and (C) Slimdek steel which its top flange is smaller than bottom flange

Cellular Composite Beams with Composite Slabs And Steel Decking

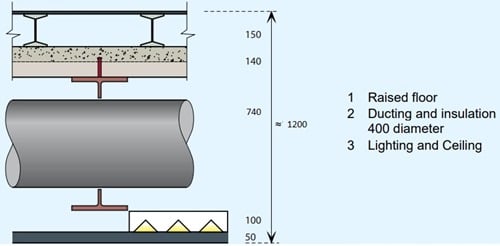

It is composed of cellular beams that support composite slab that consist of steel deck profile and top concrete. The span of the beams ranges from 10m to 18m and openings are provided in close intervals.

Commonly, the shapes of openings are circular but other shapes are feasible to employ. It is recommended to omit openings at high shear locations such as regions close to supports.

Fig.5: Beams with Various Opening Shapes

The total thickness of such floor system is around 1200mm for span of 15m and opening of 400mm. Secondary beams are normally placed at 3-4m spacing.

Advantages of this floor system are provision of large clear area without the need of columns, use lightweight utilized beams compared with other systems with the same span ranges and are cost effective.

The only disadvantage is high cost of fabrication in comparison with plain section.

Fig.6: Cellular Beam with Composite Floor Slab and Utilities

Slimflor Beams with Precast Concrete Units

Slimflor consist of slim beam and precast concrete slab that rests on the beam and reinforced concrete is used to join units together. Composite beams and non-composite beams can be used in this type of floor system.

The slim beam produced by welding 15mm thick plate to underside of beams section and exceed bottom flange by 100mm on either side.

Fig.7: Slimflor Beam

The depth of the beams is restricted to the floor depth and its span ranges from 4.5m to 7.5m and occasionally up to 10m. However, deflection of shallow beams should be contained within the code specifications.

Regarding the thickness of precast concrete slab, it is governed by the span of the slab, for example, 150mm for span of 6m, 200mm for span of 7.5m and 260-300 mm for span of 9m.

The overall floor thickness is 600mm and 1000mm for small and large services respectively.

Advantages include no need for beam fire protection for 60min, small floor thickness permits the decrease of overall structure height and shear studs can be welded off site so on-site operations are reduced.

Disadvantages are heavy steel work, extra fabrication, great connection details and more works required to deliver and install precast slabs compared with composite slab.

Fig.8: Slimflor Construction

Fig.9: Precast Concrete Slab Placed on Slimflor Beam

Long-Span Composite Beams and Composite Slabs with Metal Decking

It is composed of primary and secondary steel beams and composite slab. There are two main beam arrangements for this floor system. The slab is supported by long span beams at spacing of 3 to 4m and act as secondary beams. These secondary beams are carried by short span primary beams.

Alternatively, the slab is supported by short span secondary beams and these beams are supported by long span primary beams.

The span of long beams ranges from 10 to 15m and their spacing is 6-9m when it is used as a primary beam and 3-4m spacing used for long span secondary beam.

The overall thickness is based on the span used, for instance, 1000mm for span of 13.5m and 1200 for span of 15m.

The most outstanding advantage is the provision of large clearance area without the need for columns. Nonetheless, floor thickness is large, fire protection needed and heavy steel works required compared with short span floor systems.

Fig.10: Long Span Composite Beam and Composite Slab Construction

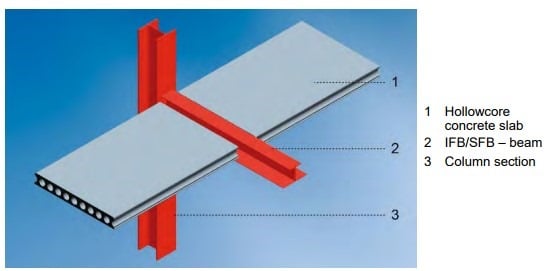

Composite Beams with Precast Concrete Units

This floor system is composed of hollow or solid precast concrete units placed on steel beams on which shear studs are welded.

The thickness of the concrete precast units is 150-160mm for hollow units and 75-100mm for solid units.

Reinforced concrete toppings are placed on the beams to connect units as can be seen in Figure-11.

It is necessary to provide adequate flange with to provide sufficient seat for the precast units.

Fig.11: Composite Beam with Precast Construction

The span of both beams and precast concrete units are between 6m and 9m, and the entire floor thickness if around 900mm.

Advantages of this floor system are smaller numbers of secondary beams are needed compared to other systems due to large concrete unit spans. Shear connectors can be welded offsite that leads to reduced onsite works.

Disadvantages include the likelihood of lateral tensional buckling of beams, careful detailing needed to encase precast concrete units and greater works are needed to transport, lift and place precast concrete units.

It is necessary to provide temporary lateral supports for beams to prevent lateral tensional buckling during construction.

Fig.12: Composite Beams with Precast Unit Construction

Non-Composite Beams with Precast Concrete Units

It consists of precast concrete units placed on steel beam flanges or shelves which are bolted or welded to the web of the beams. The shelves are used to decrease the overall thickness of floor system. Overall floor thickness is around 800mm.

Hollow core and solid precast units are suitable to be used with the same thickness used for composite construction. The span of both beams and precast concrete units ranges from 6-7.5m.

Fig.13: Hollow Precast Concrete Slab

Grouting is used for the precast concrete units after they have been placed in their position.

The advantages of non-composite beams with precast units include fewer secondary beams are needed due to long precast concrete spans.

Disadvantages involve the need for lateral temporary support for beams to prevent lateral tensional buckling, sequential precast concrete installation needed and more work are required for individual lifting and placement of precast units.

Fig.14: Non-Composite Beam with Precast Concrete Units