Design of Reinforced Concrete Footings: ACI 318-14 and IS456

Reinforced concrete footing are designed based on column loads and moments at base and the soil data. This article shed light on the design of reinforced concrete footing.

Reinforced concrete footing types

Following are the types of foundations in order of preference with a view to economy:

- Individual footings (isolated footing)

- Combined footings (combination of individual footings)

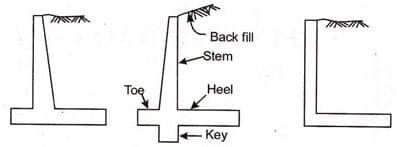

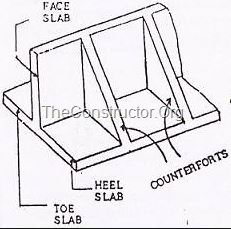

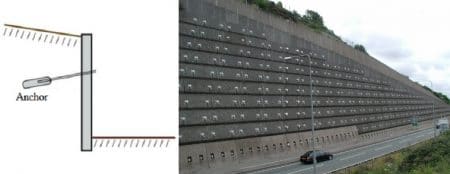

- Strip footings with retaining wall acting as strip beam wherever applicable.

- Raft foundations of the types (a) slab (b) beam-slab.

The brick wall footings can also be designed. Often plinth beams are provided to support brick walls and also to act as earthquake ties in each principal direction.

Important considerations in design of footings

footings are the structural elements which transfer loads from the building or individual columns to the earth.

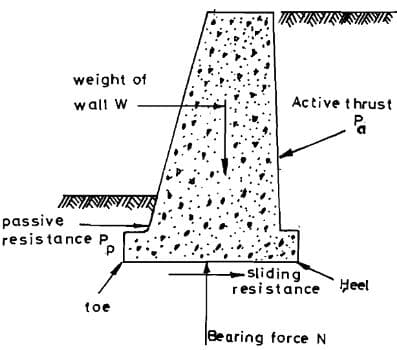

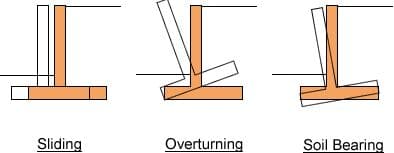

If these loads are to be properly transmitted, footings must be designed to prevent excessive settlement or rotation, to minimize differential settlement and to provide adequate safety against sliding and overturning.

Depth of footing

- As per clause 34.1.3 of IS456: 2000 and section 15.7 of ACI 318-14 the thickness of footing at its edge shall not be less than 15cmm on soils, or less than 30cm for footings on piles.

- Depth of foundation below ground level can be obtained by using Rankine’s formula:

Where:h: minimum depth of foundationp: gross bearing capacity

Where:h: minimum depth of foundationp: gross bearing capacity : density of soil

: density of soil : angle of repose or internal friction of soil.

: angle of repose or internal friction of soil.

Dimension of pedestal

In the case of plain cement concrete pedestals, the angle between the plane passing through the bottom edge of the pedestal and the corresponding junction edge of the column with pedestal and the horizontal plane shall be governed by the expression.

Where:

qo: calculated maximum bearing pressure at the base of the pedestal/footing in N/mm2

Recommendations of IS 456: 2000, Limit state design

To determine the area of foundation required for proper transfer of total load on the soil, the total load (combination of dead load, live load and any other load without multiplying it with any load factor) are considered.

Maximum Bending moment in footings

According to ACI 318- 14 section 15.4.1 and 15.4.2, and IS 456: 2000 clause 34.2.3.1 and 34.2.3.2, The bending moment will be considered at the face of column, pedestal or wall and shall be determined by passing through the section a vertical plane which extends completely across the footing, and over the entire area of the footing or one side of the said plane.

Shear capacity checks for footings

The shear strength of footing is governed by the following two factors:

- The footing acting basically as a wide beam, with a potential diagonal crack intending in a plane across the entire width, the critical section for this condition shall be assumed as a vertical section located from the face of the column, pedestal or wall at a distance equal to the effective depth of the footing in case of footings on soils. For one way shear action, the nominal shear stress in calculated as:

b: width of critical section

d: effective depth

2. For two way shear (or two way bending action or punching shear) of foundation, the following should be checked in punching shear. Punching shear shall be around the perimeter 0.5 times the effective depth away from the face of the column or pedestal.

For two way shear action, the nominal shear stress is calculated in accordance with clause 31.6.2 of IS456: 2000 as follows:

d : effective depth

When shear reinforcement is not provided, the nominal shear stress at the critical section should not exceed

Where:

Bc: short dimension of column or pedestal / long dimension of column or pedestal

The result of equation 6 is in N/mm2

Note: It is general practice to make the base deep enough so that shear reinforcement is not required.

Development length of reinforcement bars in footing

According to ACI 318-14 section 15.6 and IS 456: 2000 clause 34.2.4.3, the critical section for checking the development length in a footing shall be assumed at the following planes:

- At the face of the column, pedestal or wall, for footings supporting a concrete column, pedestal or wall.

- Halfway between the centre-line and the edge of the wall, for footings under masonry walls.

- Halfway between the face of the column or pedestal and the edge of the gussetted base, for footings under gussetted bases.

- All other vertical planes where abrupt changes in section occur.

Reinforcement in footings

The minimum reinforcement in footing slab specified by the code is 0.12% and maximum spacing specified is 3 times the effective depth or 450mm whichever is less. (clause 34.3).

In one-way reinforced footing; two-way reinforced square footing; and long direction of two way rectangular footing, the-reinforcement extending in each direction shall be distributed uniformly across the full width of the footing.

However, there shall be a central band, equal to the width of the footing for short direction of two way rectangular footings. The reinforcement in the central band shall be provided in accordance with the following equation.

Where B is the ratio of long side of the footing to its short side.

Transfer of load at the base of column

According to IS 456: 2000, Clause: 34.4, forces and moments at the base of column, walls, or reinforced pedestal shall be transferred by bearing to the top of supporting pedestal or footing.

The bearing pressure on the loaded area shall not exceed the permissible bearing stress in direct compression multiplied by a value equal to  but not greater than 2.

but not greater than 2.

Where:

For limit state design, the permissible bearing stress specified is 45 fck.

If the permissible bearing stress is exceeded either in the column concrete or in footing concrete, reinforcement must be provided for developing the excess force. The reinforcement may be provided either extending the longitudinal bars into the footing or by providing dowels in accordance with the code as given by the following:

- Minimum area of extended longitudinal bars or dowels must be 0.5% of cross-sectional area of the supported column or pedestal.

- A minimum of four bars must be provided.

- If dowels are used their diameter should not exceed the diameter of the column bars by more than 3mm.

- Enough development length should be provided to transfer the compression or tension to the supporting member.

- Column bars of diameter larger than 36mm, in compression only can be dowelled at the footing with bars of smaller diameters. The dowel must extend into the column a distance equal to the development length of the column bar. At the same time, the dowels must extend vertically into the footing a distance equal to the development length of the dowel.

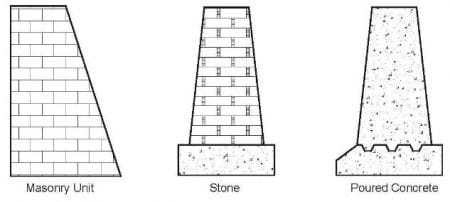

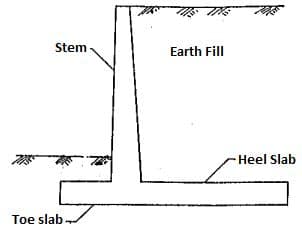

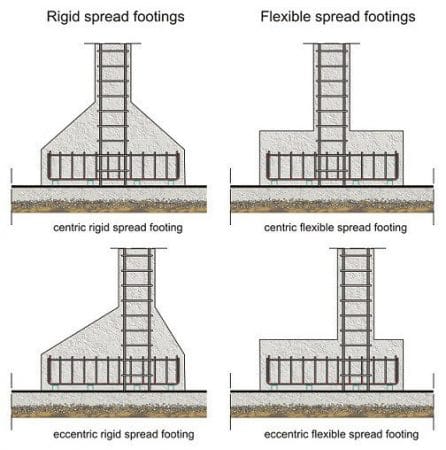

Fig.4: different types of footing with reinforcement details