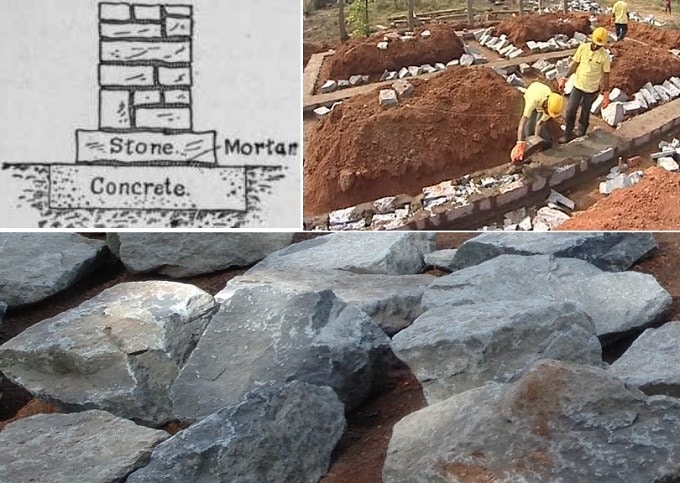

Construction of Stone Masonry Footing

The construction of stones bonded together with mortar is called stone masonry. Stone masonry footing is a structural foundation constructed to support walls. Different aspect of stone masonry footing is discussed.

Purpose of Stone Masonry Footing

The purpose of stone masonry foundation is to support structural walls and transfer load to the soil beneath it. It should serve its purpose without settlement or sinking. The load exerted on stone masonry footing should be vertical.

Fig.1: Stone Masonry Footing

Construction of Stone Masonry Footing

Dimensions of Excavation for Stone Masonry Footing

Prior to the construction of stone masonry footing, a trench with depth ranges from 1m to 1.5 m should be excavated.

The width of excavation would be controlled by amount of loads exerted on the footing. So, the width of footing is specified based on the imposed loads and properties of soil on which the footing is constructed.

Then, the soil at the bottom of the trench needs to be compacted properly. At this stage, the excavation is ready for the construction of stone masonry footing.

Fig.2: Trench excavated for stone masonry footing construction

Properties of Stones for Footing

Stones should possess the following properties otherwise they will be disqualified for the construction of stone masonry footing:

- The stone should durable

- Free from cracks

- Free from cavity

- It need to be hard and tough

Examples of stones which are desirable for stone masonry footing construction include granite, hard laminated stand stone and limestone, and bluestone.

Desired Dimensions of Stones

- The thickness of stones should be one fourth of their width

- If it is possible, the width of each stone used for the construction of footing first course should match the stone masonry footing width. If such stones are not obtainable, then joints can be provided and it is acceptable.

Preparation of Stones for Stone Masonry Construction

Stones need to be adequately wetted before they are laid in the foundation. this measure is considered to prevent water absorption which detrimentally affect the mortar.

Fig.3: Wetting stones for stone masonry footing construction

Concrete Mix Ratio used for Plain Concrete Bed

The plain concrete bed provided at the bottom of the foundation is made of one part of cement four part of sand and eight parts of coarse aggregate. The maximum size of the aggregate is 40mm.

Dimensions of Plain Concrete Bed

The plain concrete bed thickness ranges from 10cm to 15cm. The plain concrete layer should extend about 15cm from the stone masonry foundation on each side of bottom course. So, the width of plain concrete is 30cm wider than the bottom course of stone masonry footing.

Fig.4: Plain concrete at the bottom of stone masonry footing

Mortar Ratio for Stone Masonry Footing

Mortar is used between joints of stones to create required bond between then and seal the joint to avoid the penetration of water. The proportion of the mortar is one portion of cement to six portions of sand.

Stone Masonry Footing Construction Steps

- After the trench is dug and prepared, then a layer of plain concrete will be poured at the bottom of the trench.

- After plain concrete bed is set, the construction of stone masonry footing will begin with laying a layer of mortar on which first stone masonry course will be installed.

- Stones should be placed close to each other and the maximum joint between is 2 cm.

Fig.5: Filling joints between placed stones with mortar

- The face of stone should be arranged to stagger the joints

- Long vertical joints should be avoided since it would be weakness point of the stone masonry footing.

- To improve strength of stone masonry footing, bond stones will be placed at a specified spacing of 1m. This bond stones will run through the thickness of stone masonry footing.

Fig.6: Placing bond stones during the construction of stone masonry footing

- If the thickness of stone masonry footing is large, then the length of bond stone should be increased to achieve its objective. This can be obtained by installing a set of two or more bond stones overlapping each other.

- Heart stones, which are installed at the middle of stone masonry footing, should be as close to each other as possible and smaller stone sizes should be used to fill voids.

Then, heart stones and smaller stone sizes will be covered by mortar and spaces should be filled with mortar to improve footing strength.

Fig.7: Placement of heart stone in the stone masonry footing

Fig.8: Small sized stones are placed to fill voids

Fig.9: Placement of mortar over a course of masonry footing to fill spaces