What is Shoring? Types of Shoring and When it Used

What is Shoring?

Shoring is the construction of a temporary structure to support temporarily an unsafe structure. These support walls laterally. Shoring can be used when walls bulge out, when walls crack due to unequal settlement of foundation and repairs are to be carried out to the cracked wall, when an adjacent structure needs pulling down, when openings are to be newly made or enlarged in a wall.

Types of shoring

- Raking shoring

- Flying shoring

- Dead shoring

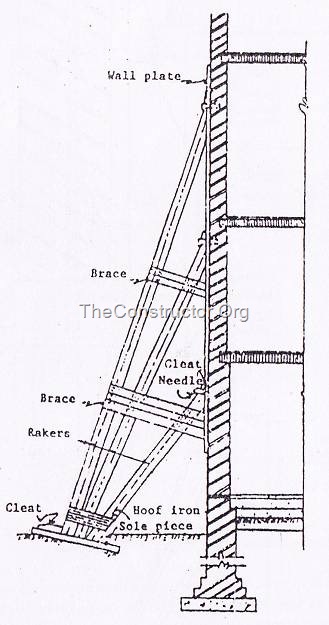

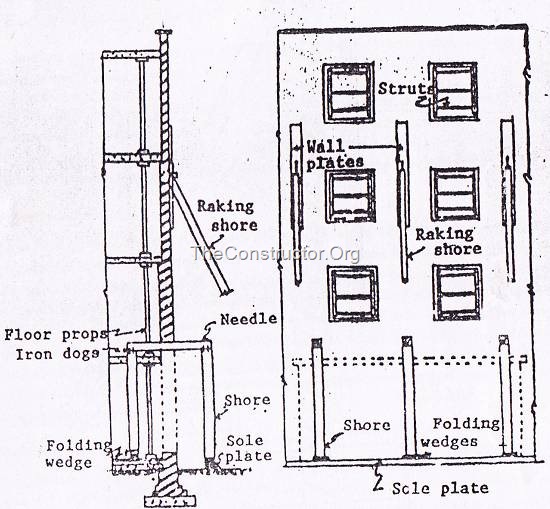

1. Raking Shoring

In this method, inclined members known as rakers are used to give lateral supports to walls (figure 1 to 3). A raking shore consists of the following components:

- Rakers or inclined member

- Wall plate

- Needles

- Cleats

- Bracing

- Sole plate

The following points are to be kept in view for the use of the raking shores:

- Rakers are to be inclined in the ground at 450. However the angle may be between 450and 750.

- For tall buildings, the length of the raker can be reduced by introducing rider raker.

- Rakers should be properly braced at intervals.

- The size of the rakers is to be decided on the basis of anticipated thrust from the wall.

- The centre line of a raker and the wall should meet at floor level.

- Shoring may be spaced at 3 to 4.5m spacing to cover longer length of the bar.

- The sole plate should be properly embedded into the ground on an inclination and should be of proper section and size.

- Wedges should not be used on sole plates since they are likely to give way under vibrations that are likely to occur.

Fig.1: Raking Shores Wall Support

Fig.2: Detail of Head of the Raker Shores

Fig.3: Raking shore for Multistoried Building where inclination of the rakers has to be limited due to short land width available

2. Flying Shoring

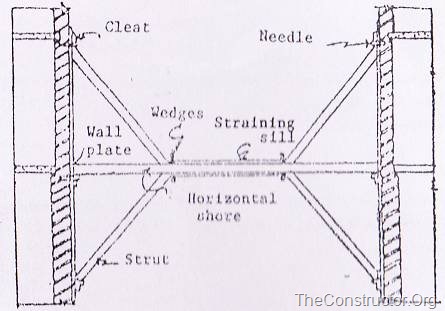

Flying shores is a system of providing temporary supports to the party walls of the two buildings where the intermediate building is to be pulled down and rebuilt (figure 4 and 5). All types of arrangements of supporting the unsafe structure in which the shores do not reach the ground come under this category.

The flying shore consists of wall plates, needles, cleats, horizontal struts (commonly known as horizontal shores) and inclined struts arranged in different forms which varies with the situation. In this system also the wall plates are placed against the wall and secured to it.

A horizontal strut is placed between the wall plates and is supported by a system of needle and cleats. The inclined struts are supported by the needle at their top and by straining pieces at their feet. The straining piece is also known as straining sill and is spiked to the horizontal shore. The width of straining piece is the same as that of the strut.

When the distance between the walls (to be strutted apart) is considerable, a horizontal shore can not be safe and a trussed framework of members is necessary to perform the function of flying shore.

Fig.4: Flying Shore

Fig.5: Flying shore when the distance between two walls is considerable

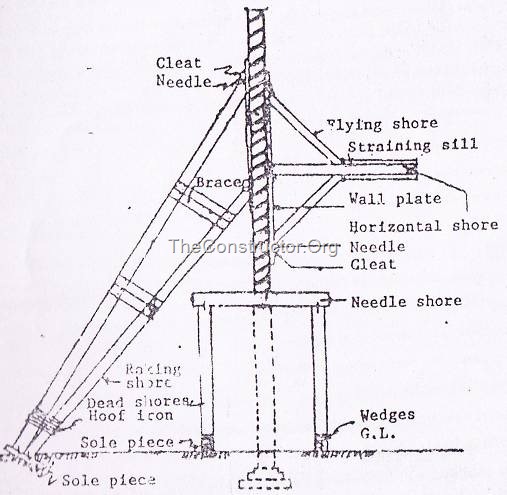

3. Dead Shoring

Dead shore is the system of shoring which is used to render vertical support to walls and roofs, floors, etc when the lower part of a wall has been removed for the purpose of providing an opening in the wall or to rebuild a defective load bearing wall in a structure (figure 6 and 7).

The dead shore consists of an arrangement of beams and posts which are required to support the weight of the structure above and transfer same to the ground on firm foundation below.

Fig.6: Dead Shore

When opening in the wall are to be made, holes are cut in the wall at such a height as to allow sufficient space for insertion of the beam or girder that will be provided permanently to carry the weight of the structure above.

Distance at which the holes are cut depends upon the type of masonry and it varies from 1.2m to 1.8m centre. Beams called needles are placed in the holes and are supported by vertical props called dead shores at their ends on either side of the wall. The needles may be of timber or steel and are of sufficient section to carry the load above.

Fig.7: Section of the elevation showing arrangement of dead shores for making an opening in an existing wall

The dead shores stand away from wall on either side so as to allow for working space when the needle and the props are in position. The props are tightened up by folding wedges provided at their bases while the junction between the prop and the needle is secured with the help of dogs.

Before the dismantling work is started, all the doors, windows or other openings are well strutted. In order to relieve the wall of load of floors and roof above, they are independently supported.

Vibrations and shocks are bound to occur when wall cutting is done as such a measure of safety raking shores are sometimes erected before commencement of wall cutting operation.