Jacketing and Collars for Concrete Column Beam Strengthening

Jacketing and Collars for Strengthening of Concrete Structures

Jacketing is the process whereby a section of an existing structural member is restored to original dimensions or increased in size by encasement using suitable materials. A steel reinforcement cage or composite material wrap can be constructed around the damaged section onto which shotcrete or cast-in- place concrete is placed.

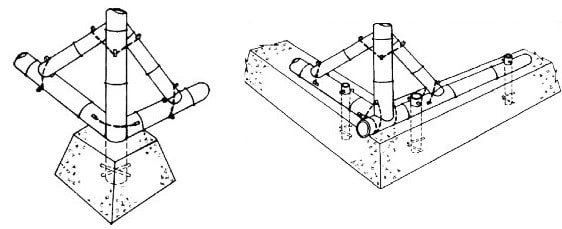

Collars are jackets that surround only for a part of a column or pier. These are usually used to provide increased support to the slab or beam at the top of the column.

The form for the jacket consists of timber, corrugated metal, precast concrete, rubber, fiberglass, or special fabric; and may be permanent in some cases. The form must be provided with spacers to ensure equal clearance between it and the existing member.

Materials, like conventional concrete and mortar, epoxy mortar, grout, and latex-modified mortar and concrete, are used as encasement materials. For jacketing, the void between the form and the existing member is filled using pumping, tremie, or preplaced aggregate concrete.

Jacketing is particularly used for the repair of deteriorated columns, piers, and piles and may easily be employed in underwater applications. The method is applicable for protecting concrete, steel, and timber sections against further deterioration and for strengthening.

Permanent forms are preferred where protection against weathering, abrasion, and chemical pollution is desired. The collar provides increased shear capacity for the slab, and it decreases the effective length of the column. Architecturally collars are considered better than jacketing but performing the same structural function.

Before applying jackets or collars, all deteriorated concrete must be removed, cracks must be repaired, existing reinforcement must be cleaned, and surfaces must be prepared. The surface preparation improves the bond of the newly placed materials with the existing structure, which is difficult for underwater repairs. For underwater conditions, a plastic shell may be applied at the splash zone to help minimize abrasion. A drawback of jackets and collars is that they occupy space that was earlier available for other uses.

Timber, cardboard and corrugated steel forms may be used as temporary or permanent forms. Permanent fiberglass, rubber, and fabric forms have gained considerable popularity because they provide resistance to chemical attack after the repair is complete.

Jacketing used for purposes other than covering the deteriorated concrete and providing lateral confinement, such as to bear longitudinal loads, needs special considerations. The existing column may have undergone full shrinkage and most of the creep and also has elastic strains due to carried loads, whereas the shrinkage and creep of the new material has to occur.

The load transfer to jacketing is also a big issue. It is better to use jacking to release the load on the member before jacketing, to use non-shrinking materials for jacketing and to hammer steel shims at the transfer points of the jacketing after curing.

If the material used for jacketing is cement mortar or concrete, the cement content must be exactly according to the requirements; both excessive and less cement contents may be dangerous. Use clean, stable and the largest possible size aggregates. In order to reduce shrinkage, control the temperature of the materials and the immediate surroundings during placing and curing.

Use of admixtures such as plasticizers, air-entraining agents, retarders, accelerators and waterproofing admixtures is more beneficial in repair than even the ordinary construction.

Expanding mortars / concretes can be made by adding aluminum powder to the matrix to overcome the setting shrinkage and some part of the drying shrinkage. The use of iron fillings or powder can also perform this function if moisture and air are available.

In case grout is used for filling the forms, it is allowed to settle for about 20 minutes after fulfilling and then is filled to overflowing condition. The top of the jacket must be finished with pneumatically projected or hand placed concrete.