Methods of Bridge Column Casing -Properties, Details and Uses

The purpose of providing bridge column casing is to improve ductility, shear and flexural capacity of the column and occasionally restricting bridge column radial dilating strain at plastic hinge areas.

There are different methods employed for bridge column casing such as steel casing, concrete casing, fiber reinforced plastic composite casing, and wire wrap casing.

Methods of Bridge Column Casing

- Steel casing

- Bridge concrete column casing

- Fiber reinforced plastic composite casings

- Wire wrap casings

Steel Casing of Bridge Columns

Generally, there are three classes of steel casing which is being practiced and used to improve seismic performance of bridge columns. The first type termed as class F type of column casing is completely grouted and it covers up the entire height of the column.

Not only does it utilized to enhance flexural capacity of the column but also improves shear capacity. Therefore, it is suitable for column with shear and flexural deficiency.

It almost completely prevents slippage of column lap splice and decline radial dilating strain to less than 0.001.

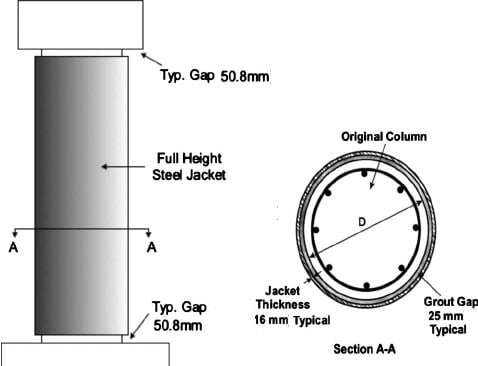

So important is the class F steel casing that increase confinement and improve shear strength considerably. Figure-1 and Figure-2 show detailing and execution of Class F type of steel casing of bridge column.

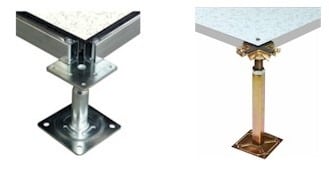

Fig.1: Detail of Class F Type of Column Casing

Fig.2: Bridge Column Steel Casing

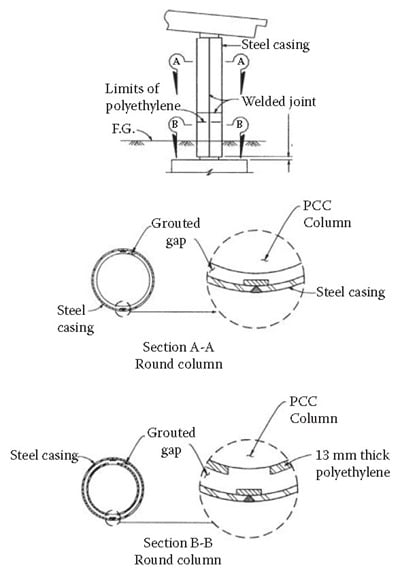

As far as the partial height column casing is concerned, it is the second category of column casing that covers part of column height. The main difference between class F and class P type is a layer of polyethylene which is not provided in the former type as it is shown in Figure-3.

It should be bore in mind that, this class of steel casing is not suitable for improving shear capacity of the member. Added to that, the class P type allows dilating strain greater than 0.001 and a pin would be created at the base of the column.

It is allowed to extended partial casing to the full height of the column for aesthetic purposes in locations where the column is highly visible.

Fig.3: Details of Class P Type of Bridge Column Steel Casing

Fig.4: Application of Class P Type of Column Casing

The third class of the column bridge steel casing is composed of the combination of the two aforementioned classes. The third class of bridge casing can be employed to improve column that does not have adequate shear strength. The details of third class steel casing is provided in Figure-5.

Fig.5: Details of Third Class Bridge Column Casing

Bridge Concrete Column Casing

Concrete casing of bridge column is considered to be a suitable option when the column shape is not common and it needs to be maintained after the retrofit for aesthetic purposes.

The requirements of new column design are employed for the design of bridge column jacking. Not only does this method increase flexural capacity of the bridge column but also enhance its shear strength in addition to improve column confinement.

The practical work includes the placement stirrups or hoop reinforcement around the column followed by drilling and bonding bars into the column as it can be seen from Figure-6.

Finally, concrete will be placed and the aesthetic appearance of the column will be maintained. It should be remembered that the practical works is messy and could be costly.

Fig.6: Placing and Bonding of Reinforcement Bars around Concrete Column

Fiber Reinforced Plastic Composite Casings of Columns

This method can be used to increase shear capacity and confinement of bridge column. it could be an economic approach for enhancing bridge column apart from the cases where the restriction the of lap splice slippage inside the anticipated plastic hinge areas is needed.

Fiber reinforced plastic composite is flexible and can be wrapped around bridge column which means the original shape of the column would be maintained. This is especially significant when the aesthetic appeal of the element is intended to be kept.

Fig.7: Bride Column Casing using Fiber Reinforced Plastic Composite

Wire Wrap Casings of Bridge Columns

This technique includes hand wrapping of prestressing strands onto the column and placing wedges between strand column interface. This system can be employed to various column shapes similar to fiber reinforced plastic composite casing.

It should be mentioned that, the wire wrap technique need extensive labor work to execute and it currently adopted for circular columns.