Methods for Repair of Small and Large Cracks in Concrete

Repair of small, medium and large cracks in concrete and repair of crushed concrete is required to enhance the strength and durability of damaged concrete members.

Repair of small and medium cracks in concrete

Small and medium cracks in reinforced concrete and masonry structures reduce their strength considerably to bear the design loads. Thus repair of such cracks is necessary to restore the designed strength of members.

The repair of small and medium cracks is done by first marking out the critical damaged zones in concrete members. Then these cracks can be repaired by injecting cement grout or chemical grouts or by providing jacketing.

The smaller cracks less than 0.75 mm width can be effectively repair by using pressure injection of epoxy.

The surface of the member near cracks is thoroughly cleaned. Loose materials are removed and plastic injection ports are placed along the length of crack at an interval equal to the thickness of the structural member. These ports are placed on both sides of the member and secured in placed with the help of epoxy seal.

When the epoxy seal has hardened, the low viscosity resin is injected into one port at a time starting from the port at lowest level and moving upwards.

The injection through port is continued till the resin flows out from the adjacent port or from the other side of the member. Then the current injection port is closed and epoxy injection is continued from the adjacent port.

This process is carried out in sequence till all the ports and cracks are filled with the grout. This method can be used for all types of structural members such are beams, columns, walls and slabs.

This method can also to repair of small cracks in individual masonry blocks or for filling large continuous cracks.

Repair of Large Cracks and Crushed Concrete:

Repair of large cracks (cracks wider than 5mm) and crushed concrete and masonry structure cannot be done using pressure injection or grouting.

For repair of large cracks and crushed concrete, following procedure can be adopted:

1. The surface of cracks or crushed concrete is cleaned and all the loose materials are removed. These are then filled with quick setting cement mortar grouts.

2. If the cracks are large, then these cracks are dressed to have a V groove at both sides of the member for easy placement of grouts.

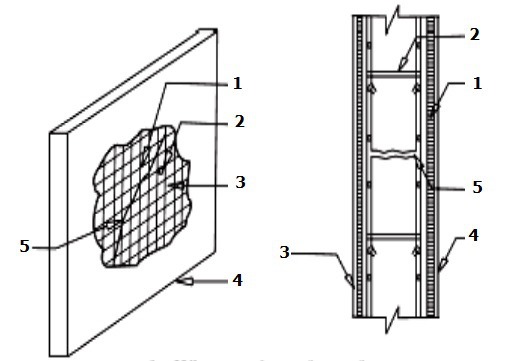

Fig: Filling of cement mortar and stone chips in large cracks in masonry walls.

3. For cracks which are very large, filler materials such as stone chips can be used.

4. Additional reinforcement and shear reinforcements can be used for heavily damaged concrete members or wherever necessary based on requirements.

These additional reinforcement should be protected from corrosion by using polymer mortar or epoxy coatings.

5. For damaged walls and roofs, additional reinforcement in the form of mesh is used on one side or both sides of the members. These mesh should sufficiently tied with existing members.

Fig: Reinforcement meshes in repair of roof slabs and walls. 1. Wire mesh on front face, 2. Clamps, 3. Wire mesh on back face, 4. Cement plaster, 5. Crack in member.

6. Stitching of cracks are done to prevent the widening of the existing cracks. In this case, holes of 6 to 10mm are drilled on both sides of the crack. Then these drilled holes are cleaned, legs of stitching dogs are anchored with short legs.

The stitching of cracks is not a method of crack repair or to gain the lost strength, this method is used to prevent the cracks from propagating and widening.