Consolidation Test on Soil by Consolidometer or Oedometer

Consolidation Test is used to determine the rate and magnitude of settlement in soils. The settlement values obtained by this test are due to primary consolidation only which is 90% of the total consolidation. The results of consolidation test are very much helpful in the design of foundations.

Apparatus Required for Consolidation Test

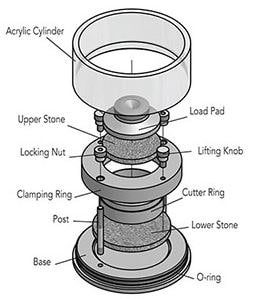

- Consolidometer or oedometer

- Consolidation ring

- Two porous stones

- Two filter papers

- Loading pad

- Dial gauge (accuracy of 0.002mm)

- Stop watch

- Knife or spatula or fine metal wires

- Weighing balance (accuracy of 0.01g)

- Vernier calipers

- Oven

- Water reservoir

Consolidation Test Procedure

Test procedure for consolidation test of soil contains following steps:

- First step is to collect the soil specimen using consolidation metal ring. The ring should be clean and dried and its weight, inner diameter and height are measured using weighing balance and calipers respectively.

- Now press the metal ring into the soil sample using hands and it is taken out with soil specimen.

- The soil specimen should project about 10 mm on either side of metal ring.

- Now trim the excess soil content on top and bottom of the rings using Knife or spatula or fine metal wires. This excess soil can be used to measure the water content of soil sample.

- Make sure that the ring should not contain any soil on its outer part and weight the metal ring with soil specimen.

- Take two porous stones and saturate them by boiling (15 minutes) or by submerging (4 to 8 hours) in distilled water.

- Assemble the consolidometer. Place the parts of consolidometer from bottom to top in the order beginning with bottom porous stone, filter paper, specimen ring, filter paper and top porous stone.

Fig 2: Arrangement of Consolidometer Parts - Place the loading pad on the top porous stone and lock the consolidometer using metal screws provided.

- Mount the whole assembly on the loading frame and center it such that the load applied is axial.

- Arrange the dial gauge in a position in such a way that it should allow sufficient space for swelling of soil specimen.

Fig 3: Dial Gauge Position - Water reservoir is connected to the mounted assembly to saturate the soil. The water level in the water reservoir should be of same level as the soil specimen.

- Now apply the initial trail load which should not allow any swelling in the soil. In general 5 kN/m2 initial load applied for ordinary soils and 2.5 kN/m2 is applied for very soft soils.

- Leave the load until there is no change in dial gauge reading or for 24 hours and note down the final reading of dial gauge for initial load.

- First load increment of 10 kN/m2 is applied and start the stop watch immediately and note down the readings of dial gauge at various time intervals. In general, readings are taken at 0.25, 1, 2.5, 4, 6.25, 9, 16, 25, 30 minutes, 1, 2, 4, 8, 24 hrs.

- In general primary consolidation of soil (90% of consolidation) is reached within 24 hours. Hence readings are noted up to 24 hours.

Fig 4: Applying Loads on Consolidometers - Next apply the second load increment of 20 kN/m2 and repeat same procedure as said in 14 th step.

- Similarly apply the load increments 50, 100, 200, 400 and 800 kN/m2 and repeat the same procedure and note down the readings.

- When values of last load increment are noted, now reduce the load to ¼ of the last load value and leave it for 24 hours. At this point note down the dial gauge reading. Reduce the load again and again and repeat the procedure until the load gets 10 kN/m2. At every point note down the final gauge readings.

- Now remove the assembly from loading frame and dismantle it.

- Take out the specimen ring and wipe out the excess water and Weigh the specimen ring and note down.

- Finally Put the specimen in oven and determine the dry weight of specimen.

Observations for Consolidation Test of Soil

Observation of consolidation test are

- Height of ring =

- Diameter of ring =

- Area of ring =

- Volume of ring =

- Weight of ring =

- Specific Gravity of Solids, G =

- Weight of ring + soil specimen =

- Initial water content =

- Initial height of specimen, H =

- Final Water Content =

- Final weight of soil specimen =

Table 1: Dial gauge readings for different loads at different times

| Intensity of load (kN/m2) Horizontal | 10 | 20 | 50 | 100 | 200 | 400 | 800 |

| Time Interval (vertical) | |||||||

| 0 minutes | |||||||

| 0.25 minutes | |||||||

| 1.0 minutes | |||||||

| 2.5 minutes | |||||||

| 4 minutes | |||||||

| 6.25 minutes | |||||||

| 9 minutes | |||||||

| 16 minutes | |||||||

| 25 minutes | |||||||

| 30 minutes | |||||||

| 1 hour | |||||||

| 2 hours | |||||||

| 4 hours | |||||||

| 8 hours | |||||||

| 24 hours |

Calculations for Consolidation Test of Soil

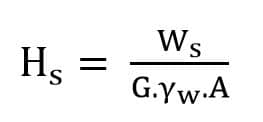

Height of solids,

Height Voids, Hv = H – Hs

Void ratio, e = Hv/Hs

Table 2: Void ratio calculation for different pressure intensities

| Intensity Pressure ( kN/m2) | Initial Dial Reading | Final Dial Reading | Specimen height, H | Height of solids, Hs | Height of voids, Hv | Void Ratio, e |

| 10 | ||||||

| 20 | ||||||

| 50 | ||||||

| 100 | ||||||

| 200 | ||||||

| 400 | ||||||

| 800 |

Graphs to be Plotted

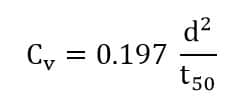

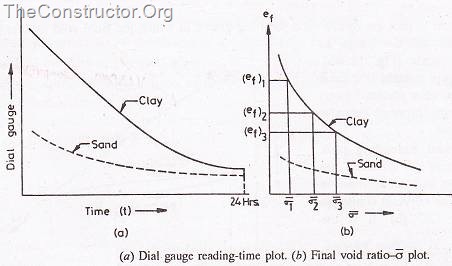

- Dial gauge reading Vs. logarithmic of time – to determine the coefficient of consolidation (Cv).

- Dial gauge reading Vs. square root of time – to determine the coefficient of consolidation (Cv).

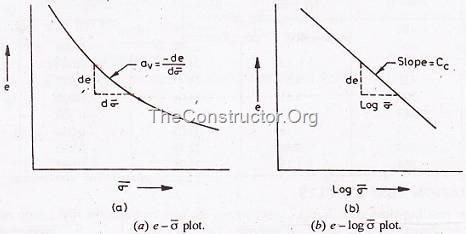

- Final void ratio Vs. Effective stress – to determine coefficient of compressibility (av) and coefficient of volume change (mv).

- Final void ration Vs logarithmic of effective stress – To determine Compression Index (Cc).

Fig 6: Void Ratio Vs logarithmic Effective Stress Graphs

Results of Consolidation Test of Soil

Consolidation Test of soils gives the following Results

- Coefficient of compressibility (av) =

- Coefficient of volume change (mv) =

- Compression Index (Cc) =

- Coefficient of consolidation (Cv) =