Operations in Embankment Dam Construction

Construction of Embankment Dam

The construction operation of embankment dams is divided into four major groups of construction activities which include:

- Material source development activities

- Foundation preparation activities

- Fill construction operation

- Ancillary works construction activities

Fig.1: Embankment Dam Construction

Material Source Development Activities

The material source development activities include opening out quarries from which necessary materials are obtained, installation of fixed plants for instance crushers, and conveyor which is employed to transfer crushed materials to a specified location.

Construction of roads between various areas of quarries and the embankment dam is another material source development activity. These roads are commonly utilized to haul and transport materials to the embankment dam, in addition to move transportation and haulage plant between various parts of the quarry.

Fig.2: Installation of plants and conveyor and road construction to haul materials

Foundation Preparation Activities

One of the first works needs to be tackled properly is drying up the foundation area. This usually can be done through the construction of temporary diversion tunnel at the sides of the embankment dam.

Fig.3: Inlet portal of diversion tunnel used in the construction of hoover dam in the united states

Such tunnel may host outlet works as well. Sometimes, the outlet culvert through or under the embankment dam is built instead of diversion tunnel and this outlet culvert would be used for river diversion.

Earth fill source development is another construction activity at this stage. This can be carried out along with river diversion works. After the previous works finished, weathered materials, which migrated due to water and weak soil at the top surface would be removed at the project site.

There are cases in which soil foundation strength needs improvement. In addition to consolidate the area in advance and install sand drains. Necessary instruments and tools are also installed at this phase.

Not only do these devices used to measure pore water pressure but also observe the performance of cutoff point. Finally, the foundation construction stage is finished with the drainage blanket placement beneath downstream shoulder.

Fig.4: Drainage blanket placement in embankment dam

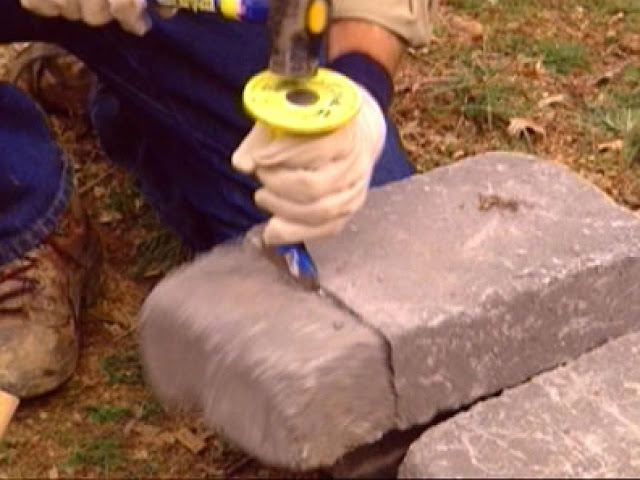

Fill Construction Operation

It is another dam construction activity that could be easily carried out. The material used should be conformed to the requirements of applicable code. As far as fill placement is concerned, it could be affected by weather conditions in addition to possible variations in material characteristics.

Fig.5: Placement of earth fill material

The quality of the construction is governed by number of factors for instance water content, thickness of soil layer being compacted, and compaction effort.

So, fill placement cannot be carried out properly unless the works is supervised and monitored adequately. The quality and uniformity of compacted core fill is considerably significant and need to be taken into consideration.

Then, the placement of horizontal drain layer in both shoulders at a vertical distance of 3-6m is proceeded. This construction activity is required to control construction pore water pressure and increase speed of consolidation in cohesive materials of low permeability.

While fill material are placed, devices and instruments needed to be placed in the core and shoulders are installed. The final activity of this stage is the construction of protection measures for instance placement of armoring layer at the upstream of the embankment dam.

Ancillary Works Construction Activities

It may involve the construction of spillway, stilling basin, tunnel or culvert for outlet works, valve towers, drainage works, wave wall, road way, and grassing of downstream face of embankment dam in the locations where weather condition would not spoil it.

Fig.6: Spillway of Darbandikhan Dam In Kurdistan Region-Iraq

Fig.7: Removing excess water using spillway of Darbandikhan dam in Kurdistan region-Iraq

Fig.8: Grassing downstream of an embankment dam