Construction of steel framed structures includes construction of its foundations, columns, beams and floors systems. Construction phases of structural steel frame are discussed.

Fig.1: Construction of Steel Frame Structure

Construction of Steel Frame Structural Elements

Steel frame structure construction procedures are as follow:

- Construction of steel frame structure foundation

- Steel column construction

- Erection of steel beams

- Floor systems used in the steel frame structure construction

Fig.2: Steel Structure Frame

Construction of Steel Frame Structure Foundation

Steel framed structure construction begins with the construction of its foundation. Generally, the types of foundation required for the given structure is based on the soil bearing capacity.

Soil investigation including surface and subsurface exploration is used to assess the condition of soil on which steel frame structure rests.

For example, when moderate or low loads are imposed, then it is advised to use reinforced concrete bearing pads or strip foundation. These foundation types transfer loads to soil capable of supporting transferred loads.

Fig.3: Reinforced Concrete Bearing Pad Foundation for Steel Frame Structure

If the strength of soil is poor and the imposed load is large, then it is recommended to consider pile foundation. The pile foundation would transfer the load of the structure to the stiff soil.

Fig.4: Pile foundation to transfer loads of steel frame structure though low soil bearing capacity of stiff soil with adequate bearing capacity

Fig.5: Steel Bearing Pile Driven into Ground

Steel Column Construction

The next step of steel frame construction is the placement of steel columns. The section of the steel is specified based on the load imposed.

There are various sizes of steel column section to choose and these steel columns are commonly produced in advance.

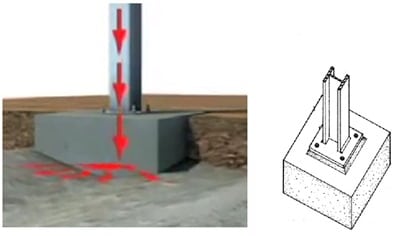

The most significant point in column installation is the connection between foundation and column and splices between columns.

Regarding foundation to column joints, base plates are welded to the end of columns. The most desired shape of base plate is square and rectangular shape. Typical details of column to foundation connection is shown in Figure-6.

It should be known that, the most desired shape of base plate is rectangular and square shape because such plates provide largest spacing between the bolts which is desirable.

Fig.6: Steel Column to Foundation Details, (A) Top bolt places created in base plate, (B) Side view of column base to foundation

As far as column splices are concern, it is provided in every two or three storey to ease erection process in addition to simplify steel column production and deliveries.

The distance between floor and column splice is about 60cm. When circular steel columns are used, weld connection is used to join both steel columns above and below.

Fig.7: Column Splices

Erection of Steel Beams

Various prefabricated beam sections are available to be used in the construction multi storey steel frame structure. Beams commonly transfer loads from floors and roof to the columns.

Steel beam members can span up to 18m, but the most usual range of steel beam spans rang from 3m to 9m.

While steel beams are erected, column to beam connection and beam to beam connections are encountered. There are different types of column to beam connection which are selected based on the type of loads imposed on the column to beam joint.

For example, if the joint is subjected to vertical loads only, then simple connections are used. Flexible end plate, fin plate and double angle cleat are examples of simple connections which are shown in Figure-8.

Fig.8: Different types of column to beam connection suitable for the case where vertical loads are applied solely: (A) Flexible end plate, (B) fin plate, (C) Double angle cleat

If the joint is subjected to both vertical loads (shear force) and torsion forces, then full depth end plate connections and extended end plate connections should be considered as shown in Figure-9.

Fig.9: Full depth and extended end plat connection used when the column to beam connection subjected to both shear and torsion stress

As far as beam to beam connection is concerned, end plate beam to beam connection is used to join secondary steel beams to primary steel beams.

Since top flange of secondary beams support floor system, so it must be leveled with top flange of the primary beams. This can be obtained by notching the top flange of the secondary beam as shown in Figure-10 and Figure-11.

Fig.10: Notched Part of Secondary Beam

Fig.11: End Plate Beam to Beam Connection

Alternatively, projected bracket is welded to the primary beam and then secondary beam is attached without the need for notching secondary steel beams as shown in Figure-12.

Fig.12: Provision of Bracket Welded to Primary Steel Beams

Floor Systems Used in Steel Frame Structure Construction

There are various types of floor systems which can be used in the steel frame structure construction. Floors are commonly installed as the beams are erected.

Not only do the floors systems support vertical applied loads but also they act like diaphragms and resist lateral loads through the use of bracings.

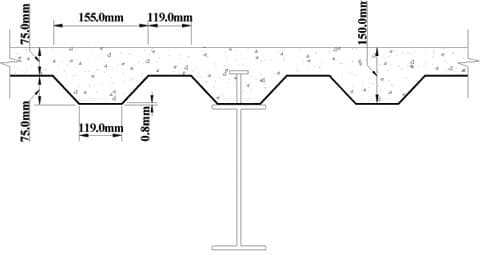

Examples of floor systems include Short-span composite beams and slabs with metal decking, Slimdek, Cellular composite beams with slabs and steel decking, Slimflor beams with precast concrete units, Long-span composite beams and slabs with metal decking, Composite beams with precast concrete units and Non-composite beams with precast concrete units.

Fig.13: Details of Composite Floors used in Steel Frame Structure

Fig.14: Precast Concrete Slab Placed on Structural Steel Frame

Construction of Bracing and Cladding in Steel Framed Structures

Bracings are used to resist lateral forced imposed on structure and it transfer lateral loads to the columns and then to the foundation.

Fig.15: Bracing with Connection Details

Regarding cladding of steel frame structure, various types of cladding such as brick cladding and sheet cladding can be used to protect the inside area of the structure.