Tensile Piles or Uplift Piles – Piles Under Tension – Analysis and Design

Pile foundation that is constructed to resist the uplift forces can be called as Tension Piles.These are also called as uplift piles or anchor piles. In those areas where there are chances of extraction of piles from the ground, the uplift piles will work well.

Foundations are broadly classified as deep and shallow foundations based on the load carrying capacity and the properties of the soil at the site. The most widely used type – Pile foundations, come under the category of deep foundations.

Any foundation structure that have a depth greater than three times the breadth of the structure can be categorized as pile foundations. Pile foundations form slender and columnar structures intended to transfer mainly compressive loads from large superstructures. The below-transferring medium may be either weak soil or a stratum that is compressible or a strong rock stratum like structure.

Tension Piles Under Uplift Forces

Different reasons for the development of the uplift forces are the:

- Seismic Forces

- Overturning Moments

- Hydrostatic Pressure

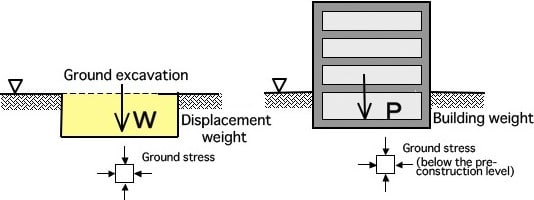

These forces are expected in the construction of large structures like transmission towers, jetties, tall structures, chimneys, jetties etc. Most of the skyscrapers are subjected to higher wind loads or seismic forces that induce overturning moments which in turn result in uplift. Uplift forces can develop because of hydrostatic pressure, seismic activity or overturning moments.

When the structure undergoes overturning, one end is subjected to compression and other tension force. These forces must be transmitted safely to the ground with the help of the foundation (Pile) constructed. This will prevent the uplift caused. The transmission of the loads to the bottom strata is carried throughout the length of the pile.

The construction of tension piles transfers this uplift force safely with the action of friction along the pile length which is acquired by under-reaming. The tension piles use sheet piling walls to resist the horizontal forces if any.

The vertical piles installed to serve this purpose must possess sufficient depth which is the main factor resulting in the shaft friction to resist the uplift forces. Different modifications in the piles can bring reduction of uplift forces to a large extent.

Uplift Resistance of Piles and Tension Piles

It is recommended to have a long pile in depth to take up the uplift load in the shaft friction. In some situation, it may be difficult to incorporate the long depth due to the presence of a hard rock stratum below the soil. So, to mobilize the remaining frictional resistance, it must be augmented through the addition of dead weight to the pile. This will help overcome the uplift forces. Another solution for this issue is the anchoring of the pile to the rock stratum.

Fig.1. Piles Provided Under the Floor for a Shipbuilding Dock

In the other side, the addition of dead weight for the piles is found uneconomical. In some applications like shipbuilding (Figure-1), it is necessary for the piles to take up alternative compressive loads and uplift forces.

An increase in dead weight in such situations will tremendously increase the construction costs and the compression rakers will be subjected to high compression loads. These issues can be solved by providing anchors for the piles that will be taken down to the rock layer.

Design of Piles for Uplift Pressure

The design of the pile foundation (Tension Piles) is performed such a way that no complete overturning or collapse has to occur under extreme conditions of loading or undergo a displacement at any severe combinations of the working loads. This consideration will not affect the functioning of the foundation under severe load conditions.

The country and the followed codes and specifications will define the maximum or the permissible displacement possible for the piles.The ultimate resistance of the pile and the pile group is determined for design when displacement is not a concerned factor. The allowable loads can be calculated by adding a factor of safety to the computed load in the design of pile foundation for uplift pressure.

Analysis of Tension Piles

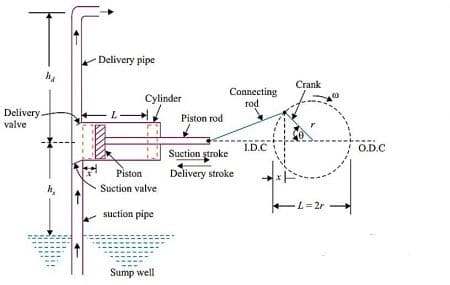

The universal approach followed for the analysis is the Limiting Frictional Approach. The method will evaluate the uplift resistance of the piles. The piles under uplift might be subjected to uplift pressure that will result in the failure surface. The formation of failure surface is one mode of studying or analyzing the failure in the piles. Another method is to derive empirical relations through experimental investigations. In analysis, piles are considered as cylindrical shaft.

Given below is a brief idea of analysis of single pile laying in

1. Clayey Soil

The Ultimate Uplift Resistance Qu = caAs + Wp

Here, ca = average adhesion along the pile shaft

Wp = Weight of the Pile, The embedded pile will possess a surface area As and the undrained cohesion value is cu.

Fig.2. Relationship between Ca/Cu & the Cu (Undrained Shear Strength)

The figure-2 below shows the graph between Ca/Cu and Cu developed by (Sowa, 1970). These values in the chart is developed almost correctly for a pile under downward loading. The ratio Ca/Cu is more for soft clays and the stiffer clays will have lesser value.

2. Sandy Soil

The gross uplift Qu in the case of piles that is placed in sandy soil is dependent on the skin resistance. The skin resistance will be developed between the pile shaft & the soil.

If d is the diameter of the pile, ‘L’ is the embedment length,

Where the coefficient of earth pressure is given by Ks, the soil pile frictional angle is  is given by the effective unit weight of the soil.

is given by the effective unit weight of the soil.