Grading of Bitumen- Different Methods of Bitumen Grading

There are different methods of grading of bitumen such as chewing, penetration grading, viscosity grading and superpave performance grading of bitumen which are discussed in this article.

History of Bitumen Grading

The correlation between the bitumen stiffness and temperature varies with the type of bitumen employed. The bitumen type varies based on their origin as well as a method of refining.

The figure below explains this, where it is observed that bitumen A and Bitumen B have different relationships with temperature.

Fig.1: Graph representing relationship between temperature and stiffness for different bitumen

Due to these variations, it was necessary to fix a test temperature. A temperature at which the grading of bitumen can be carried out. This will also give a way to compare different binders of bitumen. For example, if we have bitumen A and B, bitumen B at 25oC is stiffer than bitumen A at the same temperature. But at 60 degree Celsius the condition is reversed.

The bitumen stiffness at a lower temperature is also an essential criterion to have resistance against thermal cracking. The above explanation of bitumen A and B are from the estimates obtained for three temperatures 25, 60 and 135 degree Celsius as shown in figure-1.

The temperature of 135 degrees is near to those temperatures at which the bitumen mix is used for mixing and compacting during the construction. This temperature would give bitumen possess a motor oil form; thin in layers. This state makes them be easily mixed with aggregates.

To have proper mixing and compaction temperatures for asphalt mixtures, it is necessary to find the stiffness of bitumen. Here the stiffness in terms of kinetic viscosity must be determined.

The temperature 60 degree Celsius is similar to a temperature of the bituminous pavement on an extremely summer day. Here the possible failure caused will be rutting. The determination of stiffness at 60 degrees will be more useful in bringing adequate resistance in the summer season. Based on this value, a minimum stiffness value for the binder can be maintained. Here the stiffness is determined in terms of viscosity.

Fig.2: Rutting Damage Caused in Bituminous Pavement Just after few period of construction

The average annual temperature of an asphalt pavement during a year is almost near to 25 degree Celsius. The stiffness determination of bitumen at 25 degrees will help us to find the maximum stiffness that is needed to resist the damages like fatigue cracking or raveling.

These damages are caused after five to ten years of service life i.e. with age. Rutting is caused just by construction. But raveling is caused after a duration showing the inadequacy of the structure.

Fig.3: Fatigue Crack formed in Bitumen pavement after certain age

Different Methods of Grading of Bitumen

Following are the different methods used for grading of bitumen

- Grading by chewing

- Penetration grading

- Viscosity grading

- Superpave performance grade

Grading of Bitumen by Chewing

During the 19th century, chewing was the method used to determine the stiffness i.e. hardness if the bitumen. This was the time when no penetration test was developed. It was carried out by experienced US inspectors. Based on the test conducted, the sample was either accepted or rejected. The temperature of bitumen tested was such that, it favors human body temperature.

Penetration Grading of Bitumen

The American Society for Testing Materials (ASTM) D 04 carried out bitumen grading at a temperature of 25 degree Celsius for the testing of the road and pavement materials in 1903.

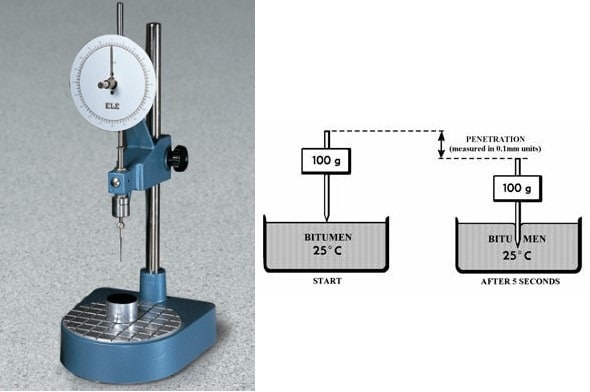

The penetration test involves penetration of a needle that is loaded by 100g, into a bitumen sample maintained at a temperature of 25-degree Celsius in a water bath for a period of 5 seconds. The penetration value is measured in millimeters.

1 penetration unit = 0.1mm.

The greater the penetration value, the softer the bitumen become. The ASTM standard D 946 gives 5 penetration grades for the bitumen binders. They are:

- Hardest Bitumen Grade 40 –50

- 60 –70

- 85-100

- 120-150

- Softest Bitumen Grade 200-300

The penetration grading system is 100 years old bitumen grading method. In India, before 2006, the most widely used grade of bitumen was 60 to 70. For the construction of low volume roads and to perform spraying, penetration value from 80 to 100 was used.

The disadvantages of penetration grading of bitumen are:

- The method of penetration grading is not a fundamental test. It makes use of empirical tests.

- For polymer modified bitumen, this method cannot be employed

- At higher and lower temperatures during service, similitude at 25 degree Celsius affects the performance. As shown in below figure, three bitumen binders with 60 to 70 penetration grade is plotted against stiffness values.

Fig.4: Graph representing relationship between stiffness and temperature of three binders A, B and C with penetration grade 60 -70

The three binders A, B, and C have same stiffness vale of 65 at 25 degree Celsius, but different values at higher and lower temperatures. Hence the bitumen C is subjected to rutting under higher service temperature, as its stiffness is low at higher temperatures.

- To guide the contractors for asphalt mixing and to know the temperature of compaction, no bitumen viscosity is available.

- The temperature susceptibility of the binders is not controlled by the penetration grading. The temperature susceptibility is the slope of temperature v/s stiffness line. Steep slope curve represents high temperature susceptible binders, which are not appreciated. This is because, at high temperatures, they are very soft and low temperatures they are stiff.

Viscosity Grading of Bitumen

In the 1970s, US introduced the method of viscosity grading at 60 degree Celsius. This was to ensure a solution for construction problems and to have high temperature performance. These were tender mixes that must undergo mix pushing and shoving under the roller, without which it cannot be rolled properly.

Prior to 1970s, the US construction used 60 to 70 penetration grade that shows variation towards rutting action. They showed lower viscosity at 135 degree Celsius. This caused tender mix problems during the construction process.

The viscosity test, unlike penetration grading, is a fundamental test carried out at 60 degree Celsius. This temperature is the maximum temperature to which the road pavement is subjected to at summer. The measurement is in terms of Poise.

In India, the equipment for testing the viscosity at 60 and 135 degrees are available. They are very simple to handle with. In the US, Six Asphalt Cement (AC) viscosity grades were specified. They are,

Grade

|

Viscosity at 60 degree Celsius, Poises

|

| AC -2.5 SOFTEST | 250±/-50 |

| AC-5 | 500±/-100 |

| AC-10 | 1000±/-200 |

| AC-20 | 2000±/-400 |

| AC-30 | 3000±/-600 |

| AC-40 HARDEST | 4000 ±/-800 |

In the US, Bitumen is mentioned as asphalt cement or asphalt. The grades with lower viscosity i.e. AC-2.5 and AC-5 were used for cold service temperatures; areas like Canada. In Northern tier states, AC-10 was used. Mostly in the US, AC-2- was used.

Only five grades excluding AC-30 was initially determined. These have a mean viscosity that will double from grade to grade. This resulted in no overlap in viscosity range. But the problem of AC-20 to be too soft and AC-40 to be too hard, that was faced by countries Florida, Georgia, and Alabama made AC-30 to be incorporated and hence six grades.

The figure below shows the AC-30 bitumen viscosity grade which is equivalent to VG-30 in India.

Fig.5: Graph representing temperature and stiffness (in terms of viscosity) relationship of AC-30 (VG-30) Bitumen

Advantages of Viscosity Grading of Bitumen

The advantages of viscosity grading system are:

- Same rutting performance is given by the binders of same viscosity grade, unlike the case of penetration grades.

- The viscosity grading system retains minimum performance in terms of fatigue cracking. This will enable acceptable performance. This is for an average yearly temperature of 25 degrees.

- The potential on tender mixes can be minimized with the minimum specified values of kinematic viscosity at a temperature of 135 degrees Celsius.

- The maximum allowable temperature susceptibility can be established by specifying the minimum value of penetration at 25 degrees and the kinematic viscosity at 135 degrees.

- For a wide variety of temperatures, the viscosity binders were employed. A temperature of 60 degrees for rutting, 25 degrees for raveling or fatigue problems or 135 degrees for construction activity.

- The suppliers can provide the users with accurate asphalt mixing and temperature values for construction. This is possible because of the measurement of viscosity at two temperatures.

Superpave Performance Grading of Bitumen

The performance grading of bitumen is based on the evaluation of the material performance when in use, unlike being rational as in viscosity grading system. The viscosity grading system is more into experience based method of grading. And this has proved to have excellent performance for over 20 years in US pavement construction.

The Superpave grading was developed as a part of a 5year strategic highway research planning (SHRP) from 1987 to 1992, to have a performance based grading system for bitumen. These were developed based on the engineering features that will help in solving many of the engineering problems.

Features of Superpave Performance Grading of Bitumen

The Superpave performance grading system make use of a new set of bitumen tests. The method incorporates the following salient features:

- The system includes tests and specification for bitumen binders. This bitumen binder may have either modified or unmodified bitumen.

- The field performance by the engineering principles will influence the physical properties determined from the Superpave bitumen tests. That is, it is not achieved by experience alone.

- The bitumen simulation for a period of 5 to 10 years, to understand its performance with age was developed. This is a long-term bitumen aging test.

- The tests and specification of Superpave system intend to avoid three main damages in bitumen i.e. raveling, fatigue cracking and thermal cracking. These failures happen at high, intermediate and low temperature respectively.

- The pavement is taken for testing for the entire range of temperature as shown in the figure below. A rotational viscometer is taken to determine the viscosity at 135 degree Celsius. The viscoelastic property of bitumen at two temperatures is determined with the help of a dynamic shear rheometer. The first temperature is “high temperatures” maximum 7-day temperature during a hot summer day of the project site. The second one is “intermediate temperature”, which is the average annual temperature of the pavement at the project site.

- During Winter a bending beam rheometer and direct tension tester are used to measure the bitumen rheological properties at the project site.

Fig.6: The testing carried on the pavement at project site for entire range of temperature in a Superpave grading system (As per FHWA)

The performance of Superpave is dependent on climate. The Superpave performance grade (PG) for project location where the temperature during 7 days is greater than 64 degree Celsius and a minimum temperature of -22 degrees are PG 64 to 22.

The available higher grades are PG 52, PG 58, PG 64, PG 70, PG 76 and PG 82. The lower grades are -4, -10, -16, -22, -28, -34 and so on. Both the temperature levels increment at a rate of 6 degrees.

If in Rajasthan the project site has maximum 7-day record temperature of pavement as 70 degrees and a minimum temperature of -3 degree, PG 70 to 4 bitumen will be specified for that project.