How to Protect Foundation Structures from Soils and Groundwater Attacks?

Foundation is an essential part of structures and it greatly affects structural integrity of the structure. Foundation structures are commonly subjected to different forms of attacks from underground water and soils and hence necessary protection measures are required to be undertaken.

How to Protect Foundation Structures from Soils and Ground Water Attacks?

In this article, consideration regarding the attacks on foundation structures caused by harmful elements in soils and ground water are discussed as follows:

- Causes of attacks

- Soil and groundwater exploration

- Protection of concrete foundation structures against attacks in soil and ground water

- Protection of steel piles against corrosion

- Protection of timber piles

Causes of Attacks on Foundation Structures

There are different types of attacks that various types of foundation may suffer from. The following states various causes of attacks that different types of foundations namely concrete foundation, steel piles, and timber piles may suffer from and consequently damaged.

Table-1: Types of foundation and causes of attacks

| Types of foundations | Causes of attacks |

| Concrete structure | Chemical wastes and sulfates in the ground, erosion, and mechanical abrasion, Figure-1 |

| Steel piles | Specific environmental conditions could lead to corrosion, Figure-2 |

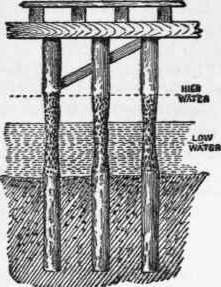

| Timber piles | Organism in soil and water may lead to decaying of timber piles, ships or ice or other floating objects cause abrasion, serious damages may occur due to shingle movement in the case where the foundation exposed to wave action, Figure-3 and Figure-4 |

The degree of the attacks is not only based on the concentration of harmful elements in soil but it is also dependent on climatic conditions and the changes in levels of groundwater table.

Fig.1: Sulfate attack on concrete foundation structure

Fig.2: Corrosion of steel piles

Fig.3: Timber piles used in the bridge construction

Fig.4: Decayed Timber Pile

Soil and Groundwater Exploration

It is substantially significant to determine groundwater table and fluctuation and existence of aggression substances in the soil since proper protection measures can be proposed based on the site condition on which the foundation is constructed on.

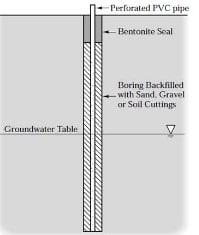

Usually, ground water, disturbed and undisturbed soil samples are taken for chemical analysis. Stand pipes may be placed in boreholes for adequate time so as to take necessary data and determine groundwater level. In this way, not only does the groundwater fluctuation can be determined but also average groundwater level can be obtained.

It is necessary to achieve enough data to specify sulfate content correctly and estimate sulfate content changes as the depth is increased. This is because uneconomical protection measures might be considered based on inadequate data.

Fig.5: Groundwater level determination

Protection of Concrete Foundation Structures against Soil and Ground Water Attacks

The major factor that lead to concrete foundation deterioration is the aggression of sulphate that present in soil and ground water. Apart from sulphate attack, chemical wastes, organic acids, specific deleterious aggregate, corrosion of reinforcement, and sea action could cause concrete foundation damages.

In the following sections, viable protection measure that can be used to protect concrete foundation structure against attacks of soil and ground water will be explained.

Protection Against Sulphate Attack

There are several techniques that may be employed to protect concrete foundation structure form attacks. According to ASTM classification, Type II Portland cement can provide a fair resistance against sulphate attack, and Type V Portland cement possess great resistance against sulphate attacks.

The most serious sulphate aggression from soil and ground water can be dealt with using super-sulphate and high alumina cement. Despite the fact that high alumina cement could suffer from conversion, which is a sudden decline of concrete compressive strength, but this issue may be tackled and there is residual strength in such concrete when it experiences conversion. An indication of high alumina conversion is the reduction of concrete sulphate resistance.

Measure to avoid high alumina conversion involves avoiding application of high percentage of cement, protect the concrete from heat, avoid steam curing, and protect concrete piles from sun in stock yards using proper shading.

For normal foundation construction, suitable compaction of sulphate resistant cement may be adequate in high sulphate concentration areas whereas protective membrane should be used in harsh situations.

It is recommended to employ and wrap plastic sheets or bituminous around concrete pad and strip foundation.

Heavy duty plastic sheeting can be used to protect cast in place and driven concrete piles and this protection layer is possible to be teared by fastenings. So, galvanized corrugated cylindrical sheeting steel sheeting or rigid PVC tubing can be used instead but it would be more expensive.

Protection of Concrete Foundation Against Organic Acid Attacks in Soils and Groundwater

Natural acids may present in peat soils and water, and free Sulphuric acid may formed as a result of oxidation of pyrite or marcasite. The former type is less aggressive if impermeable concrete is provided whereas the latter is greatly harmful for concrete.

High sulphate content and pH values are used as a sign of the occurrence of free Sulphuric and based on the pH values protection considerations are recommended. For example, if the value of pH is equal to 6 of greater, no measure is needed to consider but smaller values would require the use of sulphate resistance cement, rapid hardening cement in combination with fly ash or ground granulated blast furnace slag would provide desired protection.

Protection of Concrete Foundation Against Chemical and Industrial Wastes

Harmful chemical substances could be present in chemical works and dumped wastes. This material is difficult to deal with since concentration of chemical would vary and their identification is considerably difficult.

Therefore, if the construction site contained aggressive chemical substances such as acid waste, then it is advised to employ pile foundation that made up of precast concrete shell, hollow interior having a PVC pipe placed and filled with concrete and the outer shell work as a sacrificial over the length of the shaft in the ground that contaminated with chemical wastes.

Protection of Steel Piles Against Corrosion

Steel piles may suffer from corrosion in soils and ground water since both air and water are basic requirements for the occurrence of steel pile corrosion. Commonly, certain regions of the steel pile will act as anode areas and other areas as cathode. Consequently, rust will be formed in cathode areas whereas pitting will be created in anode regions.

Corrosion of steel piles in soil and ground water is a serious problem and it needs to be tackled properly. In the following sections, measures recommended to protect steel pile in soil and ground water from corrosion will be explored briefly.

Steel Pile Paint Treatment Protection

In this technique, sand or grit blasting treatment is initially utilized for the structure so as to achieve white metal situation. After that, a thickness of 50-75 micrometer of zinc silicate prime coat is applied on the clean metal surface. Lastly, epoxy or vinyl painting is provided as a top coat. It should be remembered that the prime coat should be in harmony with top coat.

Protection by paint treatment is used for regions of marine structures above the splash zone.

Lastly, it should be bore in mind that paint treatment is not applicable for long service life of the structure in splash zone. So, it is advised to introduce either steel plates to protect the structure or increase the thickness of the steel piles.

Fig.6: Corrosion of steel pile in marine condition

Cathodic Protection of Steel Piles

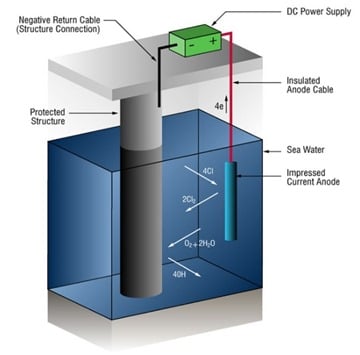

The application of characteristic electrochemical potential of metals is the basis of cathodic protection system. In this technique, the structure is turned to cathodic which avoid the migration of metals from the structure to soils or groundwater or any solution.

Power supply supplied system or sacrificial anode may be used in cathodic protection method. In the former case, anodes take the form of sizable lump carbon or scrap iron pieces. A D.C generator or other suitable means is employed to provide D.C current which is needed for the flow from the anode to the cathode.

It should be noted that by keeping the exposed surface of the structure as minimum as possible the wastage of anode will be decline and the requirements of power supply will be eased.

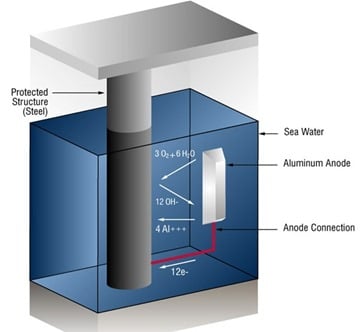

As far as the application of sacrificial anode is concerned, it composed of considerably large masses of anode metals that corrode while it offers protection during the service life of the structure.

Therefore, sacrificial anodes might need replacement after a while especially in marine environment. Moreover, electromotive series of sacrificial anode should be greater than that of structure that intended to be protected.

Lastly, it is believed that the use of sacrificial anode in marine structures is more feasible compare to power supply approach since the latter need cables which might be damaged by ships or other objects. However, the replacement of sacrificial anode need underwater replacement that may not be conducted easily.

Fig.7: Cathodic protection of steel pile using power supply

Fig.8: Sacrificial anode used to protect steel pile in water

Protection of Timber Piles

Timber used as a pile, bracing, and fences in marine conditions, so the timber decaying due to biological organism is highly possible. However, when the timber is buried, it would rarely affect by such deteriorated factors provided that it is being kept wet.

Moreover, if the timber is subjected to partial wetting and drying, then it would seriously deteriorate. Such situation may come across when buried timber piles is used in regions where water table changes.

Lastly, there are number of protection measures that may be employed to avoid pile timber damages. In the following sections, these measures will be explained.

Preservation of timber piles by creosote

It is reported that, the use of creosote to impregnate timber foundation is considerably effective way to prevent timber from deterioration due to biological and other detrimental influences.

Creosote impregnation will increase the ability of timber piles to stand for longer time and this liquid is claimed to be the most favorable among all other types of liquids used to protect timber for example water solvent and soluble types.

The effectiveness of creosote is greater in the case of softwood compare with hardwood. This is because the creosote can be impregnated to a greater depth in former case in comparison with the latter case.

It is reported that, the impregnation depth of 75mm can be obtained in the case of softwood whereas hardwood cannot be impregnated properly so it would be set under maintained pressure for a while until reasonable treatment is achieved.

Lastly, due to the fact that hardwood cannot be treated adequately, so it is advised to creosote bolt holes suitably.

Fig.9: Impregnated timber with creosote

Protection of timber piles using concrete

This approach is considered in the case where the use of creosote would not generate required final result. For example, creosote cannot be used in conditions where the level of water table changes.

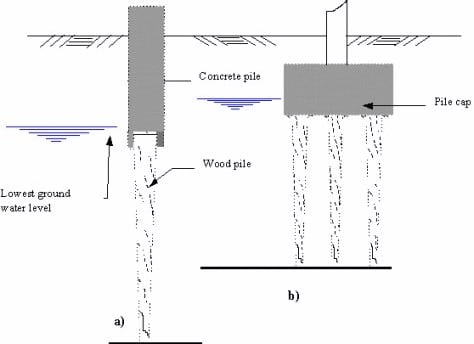

If the water table is considerably deep, then it is recommended to use composite pile which means the lower part of the pile is completely submerged which is timber whereas the upper part would be concrete.

However, when the depth of water table is reasonably shallow, then the pile is cut and the pile cap is placed at this water table level. Figure 7 illustrates the use of concrete to preserve timber pile and increase its life service.

Fig.10: The use of concrete to prevent damage of timber pile. a is considered in the case deep water table level whereas b is practices in the case of shallow water table level

Protection of Timber Piles Against Marine Borer

it is recommended to employ timber that can withstand borers at first place rather than using timber piles and providing protections against such risk. There are several timbers that naturally resist borer for example African padauk (Figure 8), Belian, Afrormosia (Figure 9), and many other types of timber piles.

Fig.11: African Padauk timber has the ability to withstand borer

Fig.12: Afromosia pile which can resist borer

It should be said that the sapwood of such timbers should be removed otherwise treatments by creosote need to be introduced. This is because sapwood of such timbers is susceptible to borer aggression.

The continuity of the treat on the surface of the timber out layer is greatly influence the treatment effectiveness. Damages of treatment by any means for example piercing the treatment layer with hooks, which may be used during lifting, or bolts or saw cut would permit the penetration or borer and cause deterioration of the timber.