How to Prevent Errors During Setting Out Building Plan on Ground?

Setting out building plan on ground is one of the most significant steps in building constructions and any errors at this stage would cause considerable problems, if it is not tackled immediately.

Errors During Setting Out Building Plan on Ground

There are different types of errors that might be made when a structure is set out for example gross errors, systematic errors and random errors.

These errors should be prevented and there are some measures to tackle these issues. These measures will be discussed in the following sections.

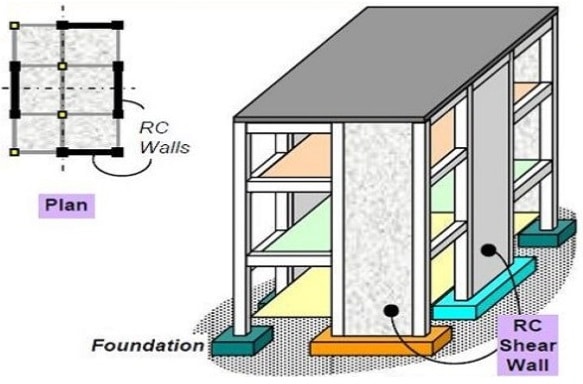

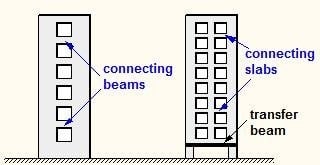

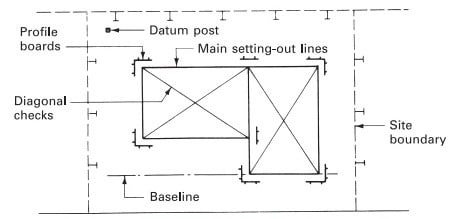

Fig.1: Setting Out of Building Plan on Ground

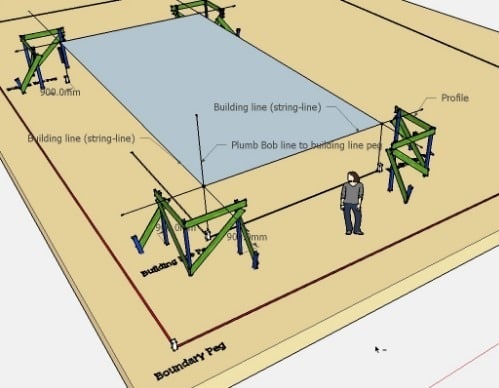

Fig.2: Setting Out Building Plan on Ground

How to Prevent Errors During Setting Out of Building?

Following are the different types of control that should be carried out to prevent any errors during setting out building plan on ground:

- Good practice in office

- On site control

- Equipment and staff

- Checks

- Marking the ground

- Use of grid offset

Good Practice in Office

To successfully set out the building, it is necessary to complete office works with great accuracy. The drawing should be the latest version and if there are any changes in the drawing, it should be checked whether it influences the work in the field or not.

It is required to examine and explore the quality of information, for example, the dimensions should be checked and confirmed with structural dimensions to make sure that it is realistic.

It is recommended to conduct calculation by two independent individual since the person who check the first computation may follow procedures and does not notice errors.

If a program is used to do calculations and solving problems, the user should know the program well and have information that the software does work. The user need to understand the results adequately otherwise unacceptable errors could occur.

On site control of Setting Out Errors

It is required to check both primary baseline and bench marks to make sure that they are accurate. Approximate setting out might be used for excavation but such work with such quality cannot be accepted for concrete work which requires considerable accuracy.

It is advised to continuously check concrete benchmark station since they can be damaged by excavations.

It should be guaranteed that correct stations are used during working and this can be done by noticing and observing stations or by taking measurements to the adjacent stations.

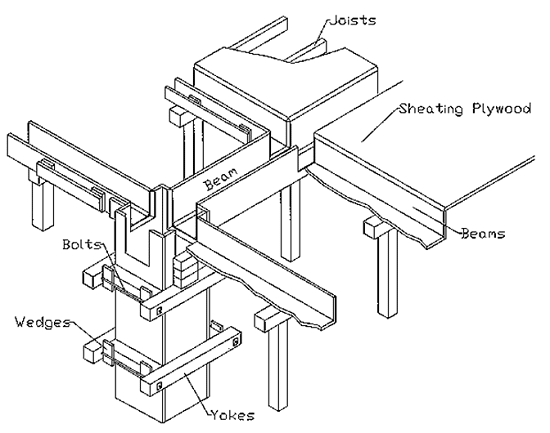

Equipment and Staff

After accurate calculations at office are finished and good control is obtained at construction site, it is considerably crucial to use a suitable instrument and experienced staff to carry out the work and get the required accuracy.

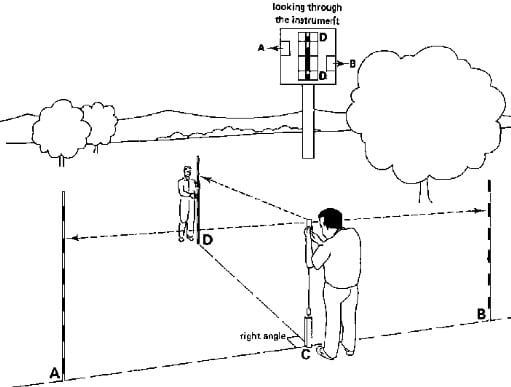

Fig:3: Equipment and Staff to Prevent Setting Out Errors

Checks to Prevent Setting Out Errors

It is recommended to do cross checks to specify any errors that have been made. For example, when a rectangular shape is set out, diagonals should be computed prior to the works to determine errors during the work in the field.

Cross checks need to be used for completed works to examine their accuracy and find out errors in the work if any exist.

It is advised to begin setting out from the major control lines and then proceed to other parts of the building to prevent accumulative errors.

It is recommended to establish secondary control points from the main control point instead of using other secondary control points to set a new one. This is because any error in one secondary control point would be repeated for other points and might increase.

For example, one houses is set out, it is preferable to set each house from the main control point rather than from another house since errors would cause considerable issues. In this case, there might not be enough space for the last house to be set.

Use of common sense at the end of the works is the last check that should not be avoided because great mistakes can be noticed and considerable cost could be saved.

Marking the Ground for Building Set Out

It is recommended to use mark setting out using proper means to make it easy to understand. The setting out would not serve any purpose if it cannot be understood by user.

The information provided on setting out should be adequate and the provision of too much information needs to be avoided. It is advised to ask the person that will use the setting out and find out what he wants about the work.

It is possible to use marks and expiations along the lines and on the wall unless it is a finished surface. Regarding offsets, they should be sensible and proper dimensions shall be used such as 1000mm.

It may be required to explain the setting out by the individual who carried out the work for a person who is going to use the setting out.

Use of Grid Offset

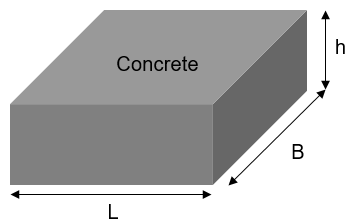

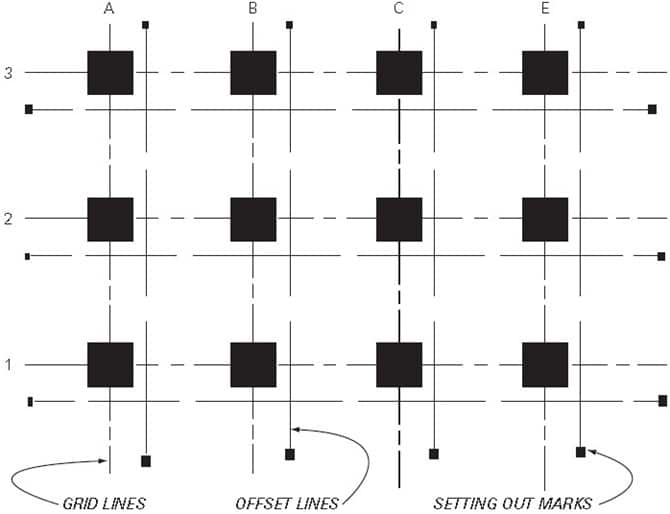

It is required to offset gridline from actual position to a new sight of line to keep the line of sight as clear as possible. This offset is recommended to be adequately large to account for size of columns and formworks.

Errors in out of square taping would be insignificant if the offset is kept small to a practical limit. In summary, no matter how offsets are established, it should not cause errors at construction site.

Regarding change in offsets, the variation should be obvious and clear such as a meter or half of a meter.

Fig.4: Gridline and Offset Line for Building Setting Out