Standard Size of Rooms in Residential Building and their Locations

Knowledge of standard size of rooms and their location in a residential building is important for planning of residential construction project. The room sizes and their location provides spaces for movement, sunlight and natural air for residents.

Standard Size of Rooms in Residential Building and their Locations

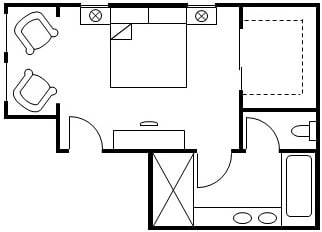

1. Size of Drawing or Living Room:

Drawing room or living room is a common, comfortable and attractive place for sitting of family members and to receive friends and guests. Sometime it is used as reception room and dining room and special occasions.

Drawing room should be located in the middle of the building and should be connected to the front verandah and dining place. It should be well-lighted and ventilated.

Generally, drawing or living room is the biggest room of the building so that it can be utilized for some ceremonial function in the house. Size of the drawing room should be determined by type of furniture to be used.

Standard size of drawing room may range from: 4200mm (14ft) X 4800 mm (16ft) to 5400mm (18ft) X 7200mm (24ft)

2. Size of Bedrooms:

Bedrooms should be so located that they are well ventilated and at the same time provide privacy. Generally, they should be located on the sides of the building so that at least one wall is exposed for good ventilation and lighting.

The bedroom should be located on the side of the direction of prevailing wind. The location should be such that the bedroom receives sunlight during morning hours. The minimum window area should be 1:10th of the floor area. In bedrooms 9.5 cubic meter per adult and 5.5cubic meter per child space should be available and suitable allowance should be made for furniture.

If good water supply and drainage system is available, a bedroom should have an attached bathroom and water closet.

Standard size of bedrooms may range from:3000mm (10ft) X 3600mm (12ft) to 4200mm (14ft) X 4800mm (16ft)

3. Size of Guest Room:

Guest room should be well lighted and ventilated. It should be located on one side of the building, generally by the side of the drawing room.

Guest should be disconnected from inside of the house and should have separated bathroom and water closet.

Standard size of guest rooms may be: 3000mm (10ft) X 3600mm (12ft)

4. Size of Verandah:

The best location for verandah is south and west. If the frontage of the building is east then they are located in east also. The verandah also serves the purpose of a waiting room. It segregates the private apartment from the entrance area.

The veranda should shade the walls of the building during greater part of the day. For this it is necessary that it must not have openings of a height greater than 2:3rd of the floor width.

Each house should have one front and rear verandah. If space doesn’t permit, the rear verandah can be omitted.

Verandah have width ranging from 1800mm (6ft) to 3000mm (10ft)

Verandah opening should always have a chajja projection for protection from sunlight and rain water.

5. Size of Office Room:

Office rooms should be on one side of front verandah, disconnected from other rooms. Sometimes an office room serves the purpose of guest room and vice versa.

Standard size of office room may be: 3000mm (10ft) X 3600mm (12ft)

6. Size of Dining Room:

Generally, the dining room should be provided in rear of the drawing or living room and near the kitchen. In modern houses drawing room and dining room are combined to have a big room for special occasions. For orthodox families dining room is kept separate.

Size of bedrooms may range from: 3600mm (12ft) X 4200mm (14ft) to 4200mm (14ft)X4800mm (16ft)

7. Size of Kitchen:

The kitchen should be provided in rear corner of the building but NE corner is the best. It should be connected with dining room and should have one approach from outside also.

If possible, the kitchen should be so located that sun light should come in the morning hours, when it is used most.

It should have windows for good ventilation and chimney for smoke escape. The window space should be min. of 15% of floor area.

Sink should be provided for washing and sufficient number of shelves should also be provided. Sometimes storeroom and kitchen are combined together, if less space is available.

Standard size of kitchen rooms may range from: 2500mm (8ft) X 3900mm (13ft) to 3000mm (10ft) X 3600mm (12ft)

8. Store Room:

Store rooms should be located near the kitchen and should have sufficient number of racks.

Standard size of store room may range from: 2500mm (8ft) X 2500mm (8ft) to 3000mm (10ft) X 3000mm (10ft)

9. Pantry:

Pantry is a small room adjacent to dining room for keeping cooked food. It should have sufficient numbers of cup-boards and shelves. For ordinary building, kitchen serves the purpose of pantry.

Size of pantry may range from: 2500mm (8ft) X 3000mm (10ft)

10. Size of Bathroom and WC:

Now-a-days it has become common practice to provide attached bathroom and water closets with each bedroom. This is preferable only when good drainage and water supply is available.

It is not attached to the bedrooms, bath and WC should be provided in rear of the building separately so that the two can be used at a time. Good ventilation should be provided for bath and WC.

There should be two windows in a bathroom. One for ventilation at a height of 2000mm above outside ground level and another at usual low level with frosted glass shutters for admitting light and maintaining privacy.

Sometimes ceiling height is kept low (2100mm or 7ft) and upper space is used for storage purpose

Common sizes of bathroom and water closet may be:

Bath and WC (combined): 1800mm X 1800mm to 1800mm X 2500mm

Bathroom (separate): 1200mm X 1800mm

WC (separate): 1200mm X 1200mm