Defects in Brick Masonry due to Poor Workmanships and its Remedies

Defects in brick masonry due to workmanship is a result of poor supervision of masonry works. Various defects in brick masonry and their remedies are discussed.

Unlike construction of reinforced concrete structure, construction of brick masonry works is generally done by mason without proper supervision as in the case of concrete works.

The strength and durability of any structural member, which is built without proper supervision always remains suspicious and uncertain. The quality of brick masonry structures would be as reliable as concrete if same level of monitoring used as during concrete works.

So, it is crucial for designer and construction engineers to have an appreciation of the workmanship factors which are significant in developing designated strength. This is proven by conducting tests on wall which have had known defects created into them and comparing with test on sound walls.

Practically, these defects in brick masonry are unavoidable and they are present to some extent, but their combination in unsatisfactorily construction lead to decrease masonry strength by as much as half of its expected strength.

It is highly important to properly construct and supervise brick masonry construction to decrease weaknesses caused by workmanship defects to as minimum as possible.

In this article, various defects caused by workmanship in brickworks will be explained.

Defects in Brick Masonry due to Poor Workmanships and its Remedies

Following are the poor workmanship which results in the defects of brick masonry construction:

- Failure to fill bed joints

- Bed joints of excessive thickness

- Deviation from verticality or alignment

- Exposure to adverse weather after laying bricks

- Failure to adjust suction of bricks

- Incorrect mixing and proportioning of mortar

Fig.1: Building Constructed with Brick Masonry

Defects in Brick Masonry due to Failure to Fill Bed Joints

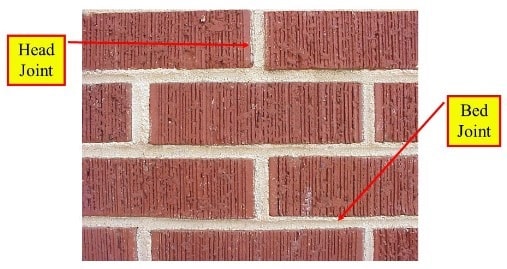

It is considerably significant that the bed joints in brick masonry be filled adequately. Improper bed joint filling or gaps in mortar may be due to too much speed or not paying enough attention or because of practice called furrowing.

Furrowing means the mason creates a gap by using his trowel in the middle of the mortar bed parallel to the face of the masonry wall.

It is demonstrated by test results that inadequate filling of bed joints can decrease masonry strength by almost 33 percent.

It is proven that failure to fill vertical joints will produce more detrimental effect on the flexural strength of masonry wall rather than masonry compressive strength.

Inadequate filling of vertical joints influence not only sound insulation of the building but also resistance against water penetration and it essentially demonstrates carelessness of the bricklayer.

Figure-2 illustrates bed joint of brick masonry walls which can be source of defects because of workmanship errors.

Fig.2: Bed Joint of Brick Masonry

Defects in Brick Masonry due to Excessive Thickness of Bed Joints

It is claimed that increasing the thickness of bed joints of brickwork leads to reduce masonry compressive strength. This is because the larger the thickness of bed joints produce larger lateral tensile stresses in brick masonry compared to the case where bed joint is thin.

Finally, bed joint with the thickness of 16-19 mm will decrease compressive strength of maximum 30% compare with bed joint with thickness of 10 mm.

Defects in Brick Masonry due to Deviation from Verticality or Alignment

Masonry brickwork which is constructed out of plumb and is out of alignment with walls of below or above storeys will lead to increase in the amount of eccentric loads and consequently reduce strength of brickwork.

It is found out that a wall that bowed or out of alignment by 12-20 mm will be approximately weaker by approximately 13-15% compare with those walls which do not have such problem.

Fig.3: Checking Vertical Alignment of Masonry Wall

Defects in Brick Masonry due to Effects of Weather

It is highly recommended to prevent newly constructed brickwork from experiencing substantial heat or freezing situations before the mortar is curried adequately and gain sufficient strength.

When masonry wall expose to hot weather it may loss considerable moisture and this can hinder the completion of cement hydration, and consequently mortar normal strength will not be obtained. It is possible that masonry strength deduces by about 10% due to loss of moisture.

Vertical displacement of masonry wall and corresponding reduction in strength can be occurred due to freezing.

The problem caused by hot weather and freezing conditions could be tackled by using proper means. For example, polythene sheet can be used to cover brickwork in hot conditions to cure it adequately, and heating construction materials may be good strategy when laying of bricks are done in freezing weather.

Fig.4: Defects in Brick Masonry due to Effects of Weather

Failure to Adjust Suction of Bricks

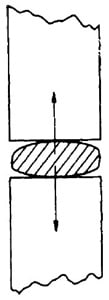

When slender walls need to be constructed with considerably absorptive bricks, small but significant problems might arise. As shown in Figure-5, the mortar shape will be changed from flat to pillow shape because of small side to side movement of the brick.

When water is lost by mortar due to brick suction, the mortar might not be able to return to its original flat shape. This lead to create unstable wall due curving or swelling out shape of mortar bed and consequently the wall might loss half of its anticipated strength which designated while bricks and mortar proportioning are specified.

This problem can be dealt with by wetting bricks prior to lying to decrease brick suction to smaller than 2 Kg/m2/min. Finally, addition an amount of lime to the mortar mixture will be beneficial because it works against brick suction and consequently retain water the mixture.

Fig.5: Effect of Moisture Absorption from Mortar Bed, Pillow Shaped Mortar Created Due to Movement of Bricks After Laying

Defects in Brick Masonry due to Incorrect Mixing and Proportioning of Mortar

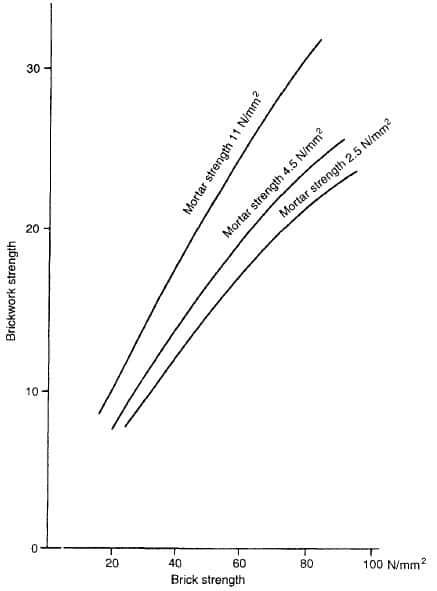

The influence of mortar strength on the masonry strength is illustrated in Figure-6. It can be observed from the figure that, for crushing brick strength of 50N/mm2, decreasing mortar strength from 11N/mm2 to 4.5N/mm2 it is anticipated that brickwork strength decrease from 14N/mm2 to 11N/mm2. And this is equal to reduction of about thirty percent cement in the mortar or changing mortar mix from 1:3 cement: sand to 1:4.5.

Fig.6: Relationship between Brick Crushing Strength and Brickwork Strength for Various Mortar Strengths

Mortar strength may also be deduced because of high water to cement ratio which is used to achieve workable mortar mix. Consequently, it is highly significant to strictly follow specifications related to the proportioning or mortar.

Nonetheless, there are small tolerances which provide enough rooms to accommodate small errors during the proportioning and mixing of the mortar.

Utilization of unnecessary or considerably large amount of plasticizer as a replacement of lime will lead to create a porous and likely weak mortar. That is why it is required to take necessary action during this situation to guard and protect the mortar.