Typical Detailing of Reinforcements in Beams and Slabs

Detailing of reinforcements in beams and slabs plays an important role in providing strength, durability and cost optimization. Reinforcement details of concrete beams and slabs should specify clearly about cover to reinforcement, length of reinforcement, curtailment of reinforcement, number and diameter of reinforcement to be provided.

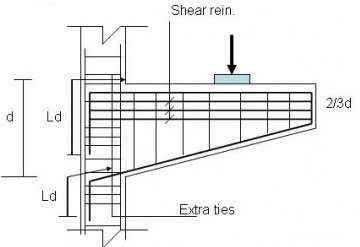

For a simply supported beam and slab, the maximum bending moment occurs at the center of the span and shear force at a distance of d/2 from the face of the support, where d is the effective depth of beam or slab. Considering this, the bending reinforcement is necessary at the center of the span and not required at the support where as shear reinforcements are required at the support.

So, it is not necessary to provide full length bending (tension) reinforcement and 50% of the reinforcement can be curtailed at suitable locations as shown in images below or can be bent upwards to provide as shear reinforcements.

Reinforcement Detailing of Simple Beams and Slabs

1. Reinforcement Details of Simply Supported Beam and Slab

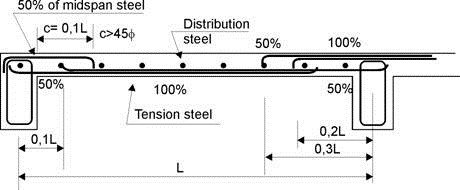

As seen in figure-1 below, for a simply supported beam and slab, 100% reinforcement as per the design is provided as tension reinforcement at the mid span of the beam and slab, and 50% is curtailed at the distance of 0.08L from the center support.

Fig.1: Curtailment of tension steel in simply supported beam and slab

2. Reinforcement Details of Continuous Beams and Slabs

For a continuous beams and slabs, the shear force and bending moment diagrams are drawn and reinforcement details are provided based on the value of the shear force and bending moment.

As can be seen from the figure-2 below, the tension reinforcement are 100% at the mid-span of the beam and slab, while it is curtailed at the distance of 0.1 L from the center of the support at end support and 0.2L at the intermediate support. L is the effective length of the beam and slab.

The shear reinforcements are provided from the support to the distance of 0.1L from the face of support on end support and at a distance of 0.3L from the center of support at intermediate support.

Fig.2: Curtailment of reinforcement in beam and slab construction

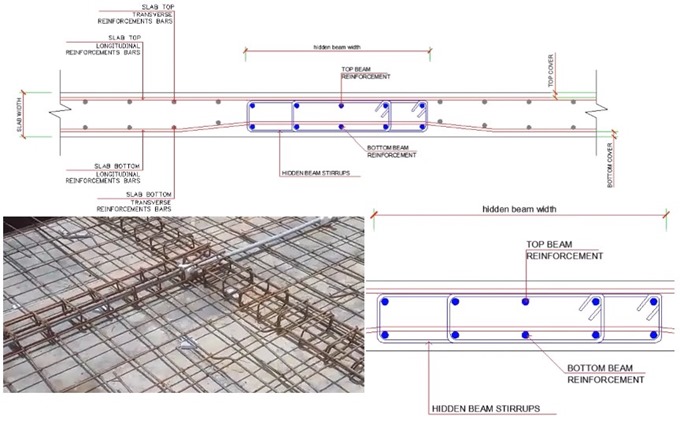

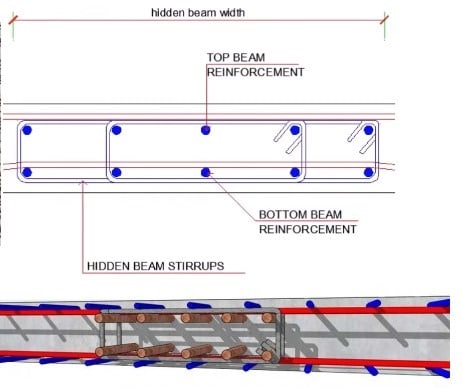

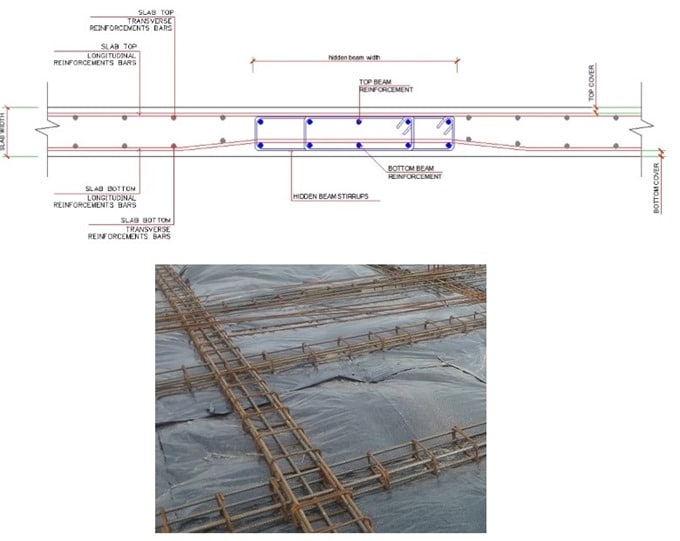

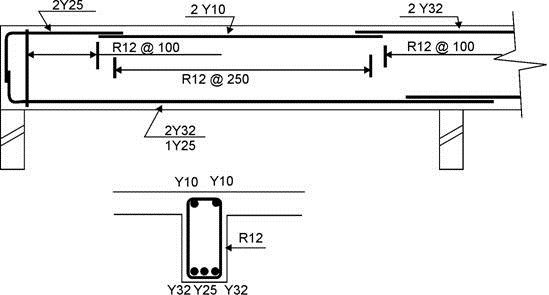

3. Typical reinforcement detail for concrete beam

The typical reinforcement details of a concrete beam shall indicate the number of reinforcements, diameter and length of reinforcement for both top and bottom reinforcements.

Fig.3: Typical reinforcement detail for concrete beam