What is a hidden beam? Purpose, Applications and Design

What is a Hidden Beam?

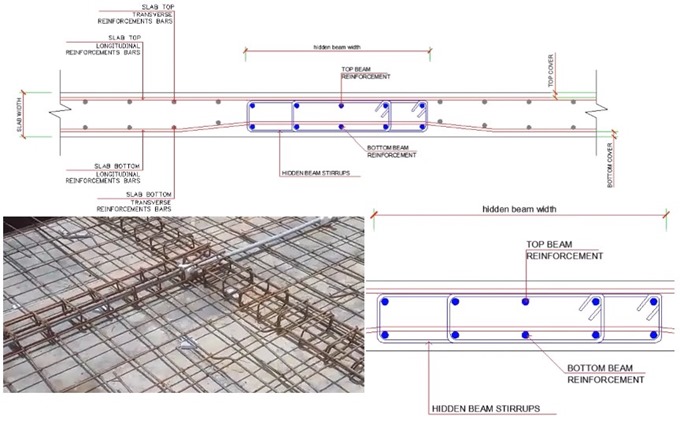

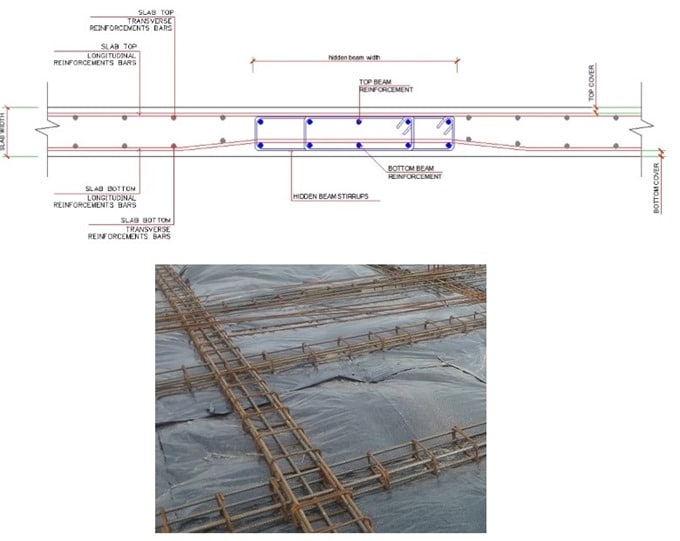

Hidden beam is a reinforced concrete beam, also called concealed beam provided within the depth of supporting slabs. So, the depth of hidden beam is the same as slab depth as it can be noticed in Figure 2. Concealed beams are popular and form an essential part of modern reinforced concrete framed structures.

Lastly, strict and rigid architectural consideration led to the provision of hidden beams. In this manner, the load which might be brick wall will be dealt with and height of the floor will not be compromised.

In this article, different aspect of reinforced concrete hidden beams will be discussed.

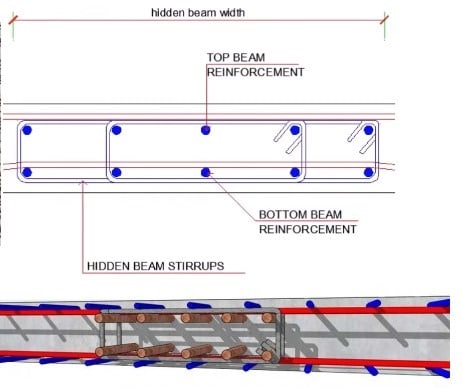

Fig.1: Hidden beams, details of longitudinal reinforcement and stirrup placement

Fig.2: Reinforced concrete hidden beam placed with a slab, its depth is equal to the slab depth

How to Design a Hidden Beam?

The design of hidden beam is the same as conventional beam, but its depth is restricted and should not be greater slab thickness. So, it may be required to increase reinforcement ration and width of the beam to overcome this restriction to a certain degree.

Fig.3: Typical reinforcement and dimension details of hidden beam

Purpose of Hidden Beam

- It is used to help disperse loads imposed on the slab for example weight of brickwork masonry wall

- It allows to use greater span for the slab

- Hidden beams are provided exclusively for architectural aesthetic purposes in the building interior

Advantages of Hidden Beams

Hidden beams are desired structural element because of several advantages which include:

- It saves on floor height clearance

- Hidden beam saves cost of formwork, labor, and materials

- It creates an acceptable aesthetic appearance which permits for efficient interior space partitioning

- Concealed beam clears the way for horizontal electromechanical ductwork

Disadvantages of Hidden Beam

The disadvantage of hidden beam is that it has considerably low ductility due to height reinforcement ratio which is provided to compensate for depth restriction specifically at column connection.

Types of slabs in which hidden beams are introduced

Hidden beams are widely used in three types of slabs which include:

- Waffle slab

- Ribbed slab

- Solid slab