Building Cracks-Causes and Remedies

Cracks in concrete have several causes. They may show total extent of damage or problems of greater magnitude.

Added to that, they may represent critical structural distress, lack of durability, or they might influence appearance only. The importance of cracks dependent on the nature of cracking and type of structure.

Causes of different types of building cracks and their remedies will be discussed below.

The principal causes of cracks in a building are as follows:

- Permeability of concrete

- Thermal movement

- Creep movement

- Corrosion of reinforcement

- Moisture movement

- Poor construction practices

- Improper structural design and specifications

- Poor maintenance

- Movement due to chemical reactions

- other factors

1.Permeability of concrete

As deterioration process in concrete begins with penetration of various aggressive agents. it dictates the ability of concrete to withstand weathering action, chemical attack, or any process of deterioration. Therefore, low permeability is a key factor to concrete durability.

There are number of factors that controls concrete permeability like water-cement ratio, use of admixtures, curing, air voids due to deficient compaction, micro-cracks due to loading, cyclic exposure to thermal variations, and age of concrete.

The first three are allied to the concrete strength as well. The permeability of cement paste is a function of water-cement ratio given good quality materials, satisfactory proportioning and good construction practice; the permeability of the concrete is a direct function of the porosity and interconnection of pores of the cement paste.

Remedial measures

The above discussion suggests suitable measure to decrease concrete permeability and hence cracks.

2.Thermal movement

Thermal movement is one of the most potent causes of cracking in buildings. All materials more or less expand on heating and contract on cooling.

Ambient temperature changes and loss of heat of hydration in portion of structure at different rate lead to temperature variations and subsequent thermal movement.

The thermal movement in a component depends on a number of factors such as temperature variations, dimensions, coefficient of thermal expansion and some other physical properties of materials.

Thermal variations in the internal walls and intermediate floors are not much and thus do not cause cracking.

It is mainly the external walls especially thin walls exposed to direct solar radiation and the roof which are subject to substantial thermal variation that are liable to cracking.

Fig.1: Concrete cracking due to temperature variations

Fig.2: Cracking due to thermal movement

Remedial Measures

Joints shall be considered during the design and constructed properly. For example, expansion joints, construction joints, control joints, and slip joints.

Fig.3: Joints to prevent cracking due to thermal movement

3.Creep Movement

Gradual and slow time dependent deformation of concrete structure under sustained loads is known as creep. It may generate excessive stress and lead to the crack development.

Creep increases with increase in water and cement content, water cement ratio and temperature.

Added to that, admixtures and pozzolans will increase creep. The increase of temperature in steel bars will increase creep as well.

However, it decreases with increase in humidity of surrounding atmosphere and age of material at the time of loading.

Fig.4:concrete building cracks due to creep movement

Remedial measures

- Use minimum possible quantity of water.

- Employ large course aggregate.

- Provide compression reinforcement if possible

- Avoid formwork removal at early ages.

- Cure concrete properly.

- assign proper cross section for the concrete element.

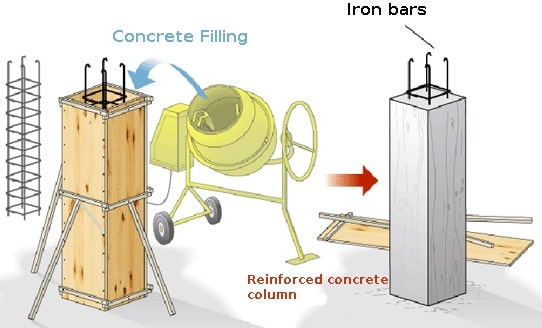

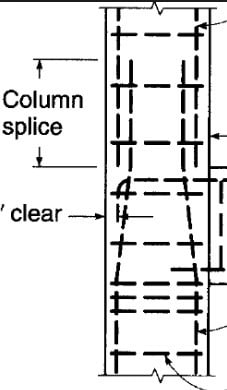

4.Corrosion of Reinforcement

Reinforcement corrosion will produce iron oxide and hydroxide on steel bar surface, consequently its volume increases.

This increase in volume causes high radial bursting stresses around reinforcing bars and result in local radial cracks. These splitting cracks results in the formation of longitudinal cracks parallel to the bar.

Reinforcement corrosion will occur unless it is protected properly. Steel reinforcement can be protected by providing adequate impervious concrete cover. This will prevent the ingression of moisture and other aggressive elements.

Steel corrosion will also not occur as long as concrete surrounding it is alkaline in nature having a high pH value.

Fig.5: Cracking due to corrosion of reinforcement

Fig.6:Concrete cracking due corrosion of reinforcement

Remedial Measures

- Use low permeable concrete

- Provide adequate cover thickness

- Make sure concrete-steel bond is as good as possible. This is because concrete alone is not capable of resisting tensile forces to which it is often subjected. Otherwise, concrete may crack and allow harmful substance materials to attack steel bars.

5.Moisture Movement

Most of the building materials with pores in their structure in the form of inter-molecular space expand on absorbing moisture and shrink on drying.

These movements are cyclic in nature and are caused by increase or decrease in inter pore pressure with moisture changes.

Shrinkage can be of plastic or dry. Factors that cause cement or mortar to experience shrinkage include excessive water, and cement quantity; rich cement mixtures suffer greater shrinkage.

Fig.7:Crack above window due shrinkage

Fig.8:concrete cracking due to moisture movement

Remedial measures

- Provide movement joints

- Use minimum possible quantity of water for mixing cement concrete or cement mortar

- Compact concrete properly; vibrated concrete suffers lesser shrinkage compare with manually compacted concrete

- Finally, avoid the use of excessive cement.

6.Poor Construction practices

There are broad variety of construction practices that lead to concrete cracking. Normally, improper construction practices are due to ignorance, carelessness, greed or negligence.

main causes for poor construction practices:

- Improper selection of materials.

- Selection of poor quality cheap materials.

- Inadequate and improper proportioning of mix constituents of concrete, mortar etc.

- Inadequate control on various steps of concrete production such as batching, mixing, transporting, placing, finishing and curing

- Construction overloads induced during construction can frequently be more serious than those imposed during service.

- Inadequate quality control and supervision causing large voids (honey combs) and cracks resulting in leakages and ultimately causing faster deterioration of concrete.

- Improper construction joints between subsequent concrete pours or between concrete framework and masonry.

- Addition of excess water in concrete and mortar mixes.

- Lastly, poor quality of plumbing and sanitation materials and practices.

Fig.9:Concrete building cracking due to poor construction practice; water added to fresh concrete

Remedial measure

- monitoring construction process properly.

- Utilize good quality materials at the time of construction.

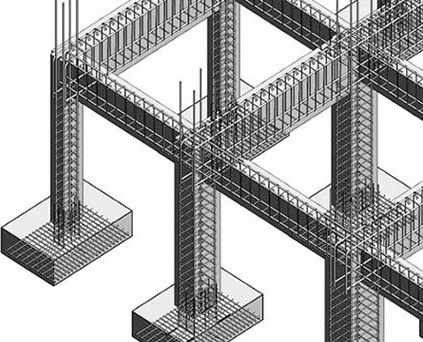

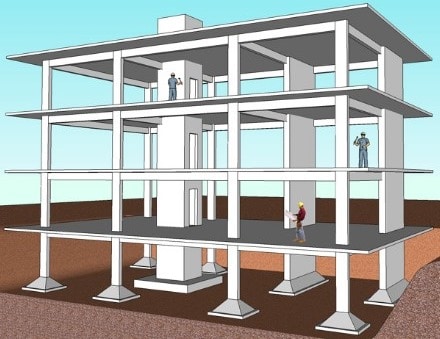

7.Improper structural design and specifications

Several problems can occur due to incorrect structural design, detailing, and specifications.

Errors that may occur at this stage include inadequate thickness, insufficient reinforcement, incorrect geometry, improper utilization of materials, and incorrect detailing.

Problems encountered due to those errors include cracking due to insufficient reinforcement, excessive differential movement due to improper foundation design, increased concentration of stresses as a result of poorly design re-entrant etc.…

Additionally, it is of crucial that the designer consider the environmental conditions existing around the building site.

Fig.10:Major structural crack in beam due to poor detailing practice

Remedial measures

Architects, Structural Consultants and Specifiers shall consider the following measure to avoid cracking and subsequent deterioration of structures:

- Proper specification for concrete materials and concrete.

- Proper specifications to take care of environmental as well as sub – soil conditions.

- Constructible and adequate structural design.

- Proper quality and thickness of concrete cover around the reinforcement steel.

- Planning proper reinforcement layout and detailing the same in slender structures to facilitate proper placing of concrete without segregation.

- Selection of proper agency to construct their designs.

8.Poor Maintenance

A structure needs to be maintained after a lapse of certain period from its construction completion.

Some structures may need a very early look into their deterioration problems, while others can sustain themselves very well for many years depending on the quality of design and construction.

Moreover, regular external painting of the building to some extent helps in protecting the building against moisture and other chemical attacks.

Water-proofing and protective coating on reinforcement steel or concrete are all second line of defense and the success of their protection will greatly depend on the quality of concrete.

Leakages should be attended to at the earliest possible before corrosion of steel inside concrete starts and spalling of concrete takes place.

Furthermore, Spalled concrete will lose its strength and stiffness. besides, The rate of corrosion increases because the rusted steel is entirely exposed to aggressive environment.

Finally, it is not only essential to repair the deteriorated concrete but it is equally important to prevent the moisture and aggressive chemicals to enter concrete and prevent further deterioration.

Fig.11:Leakage from roof slab

9.Movement due to Chemical reactions

The concrete may crack as a result of expansive reactions between aggregate, which contains active silica, and alkaline derived from cement hydration.

The alkali silica reaction results in the formation of swelling gel. This tends to draw water from other portions of concrete. Consequently, local expansion occur and results in cracks in the structure.

Fig.12:Cracking due to alkali-silica reactions

Remedial measures

- Use low alkali cement

- Employ pozzolana

- Select proper aggregates.

10.Others factors

- Brutal decoration, free to remove the load-bearing walls or holes, causing cracks.

- Fires caused by accidents, fires, mild earthquakes, etc.