Waterproofing Admixtures for Concrete – Requirement, Functions, Dosage and Mechanism

What is Waterproofing Admixture for Concrete?

Waterproofing admixture is a type of admixture which prevents the passage of water through hardened concrete under a pressure head. It is also called as water resisting admixture or permeability reducing admixture or damp proofing admixture.

Requirement of Waterproofing Admixture for Concrete

Water is a vital part of concrete construction from the mixing of concrete to the curing of concrete. But once the concrete has gained its required strength, thereafter any moisture or water penetration in concrete can cause damage to the concrete. The damage can be due to corrosion of reinforcement or due to freeze thaw.

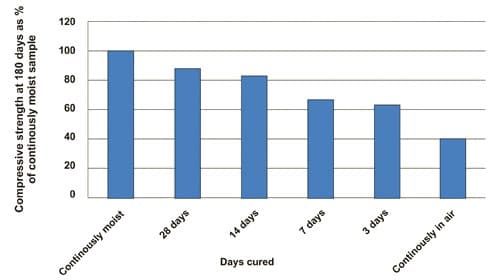

When a concrete work has finished and curing completed, the water content evaporates and leaves voids inside the concrete. Thus for a good durable concrete construction, low water/cement ratio is recommended so that porosity of concrete can be reduced. But then also, a concrete cannot be completely made waterproof even by using the minimum water/cement ratio.

Concrete is a porous material and water can penetrate through pores and micro-cracks of concrete due to capillary actions. Thus there is a need of an admixture which can control the porosity of concrete.

Functions of Waterproofing Admixtures

A permeability reducing concrete admixture or waterproofing admixtures function in following ways:

- It reduces the size of capillary pores, their numbers and continuity inside the concrete structure.

- It blocks the capillary pores of concrete, or

- It may line the capillary pores with hydrophobic materials. This prevents the absorption of water in the pores due to capillary absorption.

Capillary absorption is the passage of water through pores in concrete due to presence of an externally applied hydraulic head.

These water resisting admixtures cannot significantly prevent the movement of water through cracks in concrete or through poorly compacted concrete which are the most common reasons for water leakage in concrete.

There are many products in the market now a day which are available to protect the concrete structure from damage due to water penetration. For example, coatings, sealers, membranes etc. are used to prevent water penetration. But all these require huge amount of money and time. These process can be simplified by the use of water resisting admixture which prevent the ingress of water through concrete by making it waterproof.

American Concrete Institute (ACI) Committee 212 offers guidance on use of this admixture in its ACI 212.3 Rev10 titled “Report on Chemical Admixtures for Concrete “. Details about permeability reducing admixtures are covered in Chapter – 15 of the report.

Materials Required to Prepare Waterproofing Admixtures

The ACI 212.3 Rev.10 in its report states that following types of materials to be used in waterproofing admixtures:

- Hydrophobic or water-repellent chemicals such as oils, petroleum products which can block the entry of water into the pores by forming a layer along the pores in concrete. These materials do not fill the pores.

- Finely divided solid particles (powders)of inert and chemically active fillers to act as densifiers and restrict the movement of water through pores.

- Crystalline materials with hydrophilic nature which increases the density of calcium silicate hydrate and / or generate the pore-blocking deposits to resist water penetration.

The report does not limit the use of materials only to as mentioned above. Any material can be used as water-resisting admixture which can block the water penetration. These materials can be used as single or combination of two or more.

Dosage of Waterproofing Admixtures for Concrete:

Dosage of these admixtures vary depending on the type of admixture and the level of performance required. 2% of hydrophobic type admixture is commonly used, and may be 5% or more for the pore blocker types. These percentage is calculated based on weight or volume of concrete and not on cement.

Mechanism of Water Resisting Admixtures:

The mechanism of water resisting admixtures is to reduce the porosity of concrete. To reduce the porosity of concrete, the water content or the water cement ratio must be reduced. If water cement ratio is decreased below 0.45, the porosity of concrete reduced considerably.

If we further reduce the water/cement ratio, the workability of concrete decreases. This can be prevented by the use of water-reducing admixture that can ensure sufficient workability of concrete for full compaction and reduce shrinkage cracking.

If it is not possible to reduce water cement ratio, then there is another mechanism in which pore blocking admixtures are used. These are small in size roughly 0.1 microns and fine reactive or unreactive or insoluble polymer emulsions. During hydration process, they can settle in the pores of concrete and block them which helps the concrete to prevent further absorption of water.

The hydrophobic admixtures are soluble with the concrete but they react with calcium in fresh concrete and forms a layer which is adsorbed by the surfaces of capillaries. After the process of hydration, this layer prevents the penetration of water into the pores. But the resistance of hydrophobic admixture is limited and depends hydraulic head, the quality of the concrete and the effectiveness of the admixture.,