What are the Requirements of Partition Walls in Buildings

There are several requirements that a partition wall need to meet otherwise its purpose will be compromised.

So, it is necessary to understand partition wall requirements in order to build it with high quality and provide satisfactory performance.

This article will shed light on the partition wall requirements briefly.

Partition wall requirements are as follows:

- It shall have small thickness (thin). Thus, largest possible floor area is being used.

- Partition wall need to provide sufficient privacy in rooms in such away that occupants feel comfortable in terms of both sound and sight.

- It needs to be adequately rigid so as to be able to withstand vibrations caused by loads.

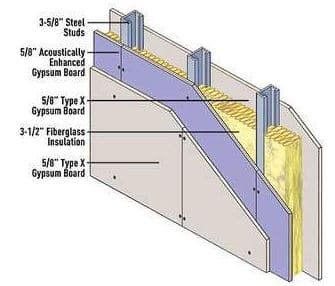

- Materials used for the construction of partition wall shall be fairly light in weight, uniform, sound, durable, and sound insulator. Fig.1 shows a soundproof partition wall.

- The partition wall materials need to have fire resistance properties so that the wall does not catch fire due to sudden short circuit or any other factors that may cause fire. Fig.2 shows fire resistant partition wall.

- The wall shall withstand heat, dampness, and fungus.

- ease of construction is another partition wall requirements.

- Partition walls are required to carry sanitary fittings and heavy fixtures for example a piece of equipment or furniture that is fixed in position.

- It should be economical.

- Finally, the partition wall need to cohere the structural wall properly.

Fig.1: Sound Proof partition wall; it withstand fire for an hour

Fig.2: Fire resistant partition wall